Hot Dip Galvanized Bolts - Hebei Longze | High Strength, Corrosion Resistance

Ağu . 01, 2025 01:20 Back to list

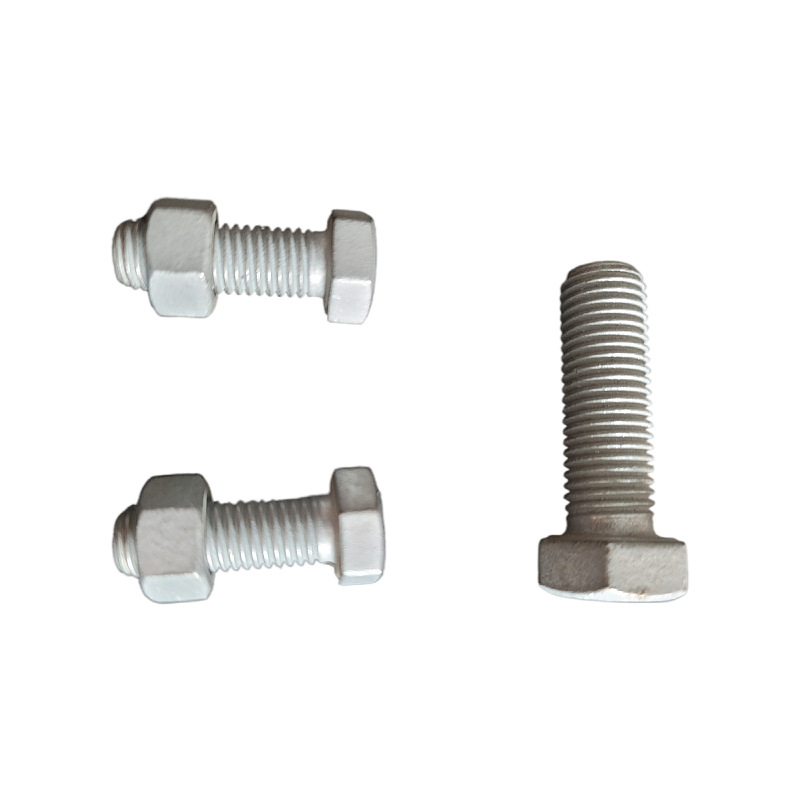

Hot Dip Galvanized Bolts - Hebei Longze | High Strength, Corrosion Resistance

Hot dip galvanized bolts are critical components in modern engineering and construction, offering exceptional durability and corrosion resistance. This article delves into the features, technical specifications, and applications of high-strength hot dip galvanized bolts, while also exploring the industry standards and the company behind this innovative product: Hebei Longze Metal Products Manufacturing Co., Ltd..

Product Features and Advantages

Hot dip galvanized bolts are designed to withstand harsh environmental conditions, making them ideal for both industrial and commercial applications. The hot dip galvanizing process involves immersing the bolts in molten zinc, creating a robust protective layer that prevents rust and corrosion. This treatment ensures longevity, even in high-humidity or coastal environments.

Key features of these bolts include:

- High Strength: Available in grades such as 4.8, 5.8, 6.8, 8.8, and 10.9, these bolts meet the demands of heavy-duty applications.

- Corrosion Resistance: The zinc coating provides a barrier against moisture and chemicals, extending the product's lifespan.

- Customization: Sizes range from M6 to M60, with lengths customizable up to 6000mm, accommodating diverse project requirements.

- Material Variety: Options include carbon steel (Q235, 45K, 40Cr) and stainless steel, ensuring compatibility with different environments.

- Surface Finishes: Available in black oxide, zinc plating, hot dip galvanizing, and more, allowing for aesthetic and functional customization.

Technical Specifications

| Parameter | Details |

|---|---|

| Size | M6-M60 (1/4"-2-1/2") or customizable |

| Length | 40mm-6000mm or customizable |

| Standards | ISO, DIN, ANSI, ASME, ASTM, BS, AS, JIS, DIN933, DIN931, ISO 4017, EN 24017 |

| Material | Q235, 35K, 45K, 40Cr, B7, 20MnTiB, A2, A4, carbon steel, stainless steel |

| Grade | 4.8, 5.8, 6.8, 8.8, 10.9 |

| Surface Treatment | BZP, HDG, BLACK, DACROMET, TEFLON, or customizable |

Applications in Industry

Hot dip galvanized bolts are widely used across multiple sectors due to their durability and versatility. Key applications include:

- Construction: For structural frameworks, bridges, and steel buildings where corrosion resistance is critical.

- Infrastructure: In road and rail projects, especially in coastal or high-moisture areas.

- Automotive: For assembling vehicle components that require high strength and resistance to environmental factors.

- Renewable Energy: In wind turbine towers and solar panel installations.

- Marine: For boat hulls, docks, and offshore platforms.

The hot dip galvanized bolts are particularly suited for environments where exposure to saltwater or chemicals is a concern, as highlighted in industry guidelines.

Company Background: Hebei Longze Metal Products Manufacturing Co., Ltd.

Hebei Longze Metal Products Manufacturing Co., Ltd. is a leading manufacturer of high-quality fasteners, specializing in hot dip galvanized bolts. With a focus on innovation and precision, the company adheres to international standards such as ISO 10684:2004, which specifies requirements for hot dip galvanized coatings on steel fasteners (ISO 10684). Their products are trusted in industries worldwide for their reliability and performance.

Hebei Longze’s commitment to quality is evident in their rigorous testing processes and adherence to NIST guidelines for material standards. Their product range includes hot dip galvanized bolts, galvanized bolts, and galvanized anchor bolts, catering to diverse industrial needs.

Standards and Certifications

Hebei Longze’s hot dip galvanized bolts comply with global standards, ensuring consistency and safety. Key certifications include:

- ISO 10684:2004: Specifies material, process, and dimensional requirements for hot dip galvanized coatings (ISO 10684).

- ASTM A153/A153M: Covers zinc coatings on iron and steel hardware (ASTM A153).

- GB/T 5267.1-2012: Chinese national standards for hot dip galvanization coatings (GB/T 5267.1).

These standards, as outlined in NIST research, ensure that the bolts meet the highest quality benchmarks for performance and safety.

Conclusion

Hot dip galvanized bolts are indispensable in modern engineering, combining strength, durability, and corrosion resistance. Hebei Longze Metal Products Manufacturing Co., Ltd. stands out as a reliable supplier, offering a wide range of hot dip galvanized bolts that meet international standards. Whether for construction, marine, or industrial applications, these bolts provide a long-term solution to challenging environments.

For more information, visit Hebei Longze’s official website or explore their product catalog.

References

Latest news

-

Premium Self Tapping Metal Screws: Strong & Easy Install

NewsAug.02,2025

-

Premium Fasteners Manufacturer | AI-Driven Solutions

NewsAug.01,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | High Strength, Corrosion Resistance

NewsAug.01,2025

-

High-Strength Hot Dip Galvanized Bolts - LongZe | Corrosion Resistance, Custom Sizes

NewsAug.01,2025

-

Best Self Tapping Screws for Drywall - Fast & Secure Installation

NewsJul.31,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&Customization

NewsJul.31,2025