Hot Dip Galvanized Bolts - LongZe | Corrosion Resistance, High Strength

Ago . 15, 2025 03:20 Back to list

Hot Dip Galvanized Bolts - LongZe | Corrosion Resistance, High Strength

Introduction

Hot dip galvanized bolts are essential components in modern construction and industrial applications, offering exceptional durability and corrosion resistance. These bolts are engineered to withstand harsh environmental conditions, making them a preferred choice for structural and mechanical projects. This article delves into the features, technical specifications, and applications of high-strength hot dip galvanized bolts, while also highlighting the role of National Institute of Standards and Technology (NIST) in establishing industry standards.

Product Overview

The hot dip galvanized bolts offered by LongZe are designed to meet stringent quality and performance requirements. These bolts are available in a wide range of sizes, grades, and materials, ensuring compatibility with diverse engineering needs. The product's versatility is complemented by its adherence to international standards such as ISO, DIN, and ASTM, as detailed below.

Key Features and Advantages

Hot dip galvanized bolts are renowned for their robustness and longevity. Here are some of their standout features:

- Corrosion Resistance: The hot dip galvanizing process coats the bolts with a layer of zinc, providing long-term protection against rust and environmental degradation.

- High Strength: Available in grades such as 8.8 and 10.9, these bolts offer exceptional tensile strength, making them suitable for heavy-duty applications.

- Customization: The bolts can be tailored to specific dimensions, including sizes from M6 to M60 and lengths ranging from 40mm to 6000mm.

- Compliance with Standards: Adherence to international standards like ISO 4017, DIN 933, and ASTM A307 ensures reliability and interoperability.

Technical Specifications

The following table outlines the critical technical parameters of hot dip galvanized bolts:

| Parameter | Details |

|---|---|

| Name | High-Strength Hot Dip Galvanized Grade 8.8 Hex Bolts |

| Size | M6-M60 (1/4" to 2.5") or customizable |

| Length | 40mm-6000mm or customizable |

| Standards | ISO, DIN, ANSI, ASME, ASTM, BS, JIS, and more |

| Material | Carbon steel (Q235, 45K, 40Cr) and stainless steel (A2, A4) |

| Grade | 4.8, 5.8, 6.8, 8.8, 10.9 |

| Surface Treatment | Hot Dip Galvanizing, Zinc Plating, Black Oxide, and more |

Applications and Use Cases

Hot dip galvanized bolts are widely used across industries due to their durability and adaptability. Key applications include:

- Construction: Structural frameworks, bridges, and high-rise buildings benefit from the bolts' strength and corrosion resistance.

- Infrastructure: Used in roadways, railways, and utility poles, where exposure to moisture and chemicals is common.

- Industrial Machinery: Essential for assembling heavy equipment and machinery that operates in harsh environments.

- Marine and Coastal Projects: Their zinc coating protects against saltwater corrosion, making them ideal for docks and offshore structures.

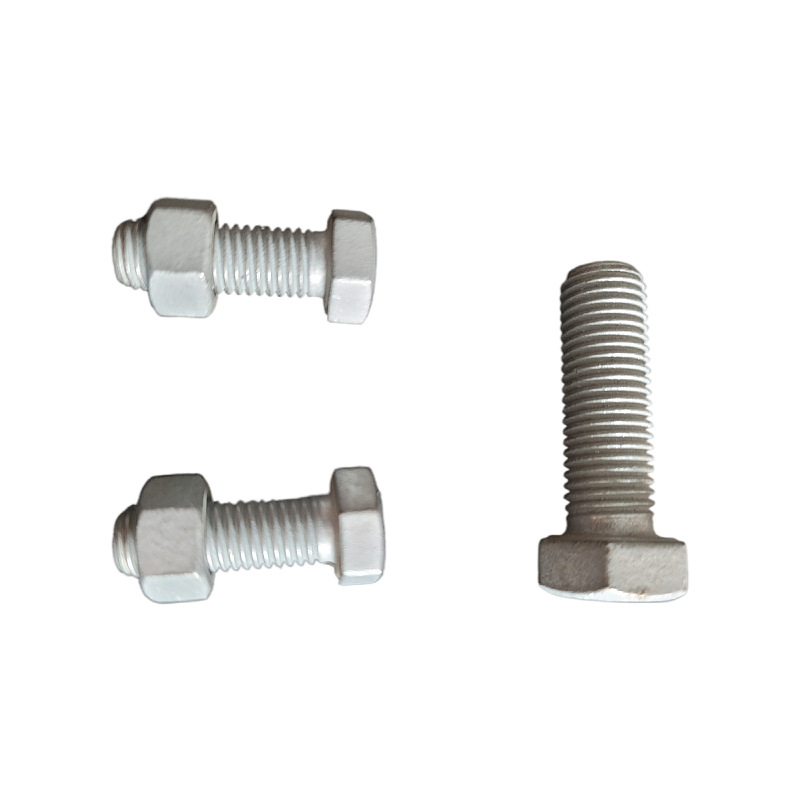

Product Gallery

Below are images of the hot dip galvanized bolts in various configurations:

Company Background: LongZe

LongZe (河北隆泽金属制品制造有限公司) is a leading manufacturer of high-quality fasteners, specializing in hot dip galvanized bolts. With over a decade of experience, the company has established itself as a trusted supplier in the global market. LongZe's commitment to innovation and quality control ensures that its products meet the highest industry standards. The company's facilities are equipped with advanced manufacturing technologies, enabling precise production of bolts that comply with international specifications.

The Role of NIST in Standardization

The National Institute of Standards and Technology (NIST) plays a pivotal role in developing and maintaining standards that ensure the safety and reliability of industrial products. According to NIST's official website, "NIST's measurements and research fuel innovation and improve the quality of life for all Americans" (NIST). This includes setting benchmarks for materials and components used in construction and manufacturing. For instance, NIST's work on standards for corrosion-resistant materials directly supports the development of durable fasteners like hot dip galvanized bolts.

Conclusion

Hot dip galvanized bolts are indispensable in modern engineering due to their superior strength, corrosion resistance, and adaptability. With a wide range of sizes, grades, and surface treatments, these bolts cater to diverse industrial needs. Companies like LongZe ensure that their products meet international standards, supported by NIST's research and guidelines. Whether for construction, infrastructure, or industrial applications, hot dip galvanized bolts remain a cornerstone of reliable and durable engineering solutions.

References

National Institute of Standards and Technology (NIST). (n.d.). Driving Innovation. Retrieved from https://www.nist.gov/

Latest news

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Customization

NewsAug.15,2025

-

Hot Dip Galvanized Bolts - LongZe | Corrosion Resistance, High Strength

NewsAug.15,2025

-

Durable Solar Panel Brackets For Sale | Roof Mounting Kits

NewsAug.15,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance, High Strength

NewsAug.15,2025

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Grade 8.8

NewsAug.14,2025

-

Hot Dip Galvanized Bolts: High-Strength Corrosion-Resistant Fasteners | Hebei Longze

NewsAug.14,2025