High-Strength Hot Dip Galvanized Bolts - LongZe | Corrosion Resistance, Industrial Applications

Aug . 07, 2025 07:15 Back to list

High-Strength Hot Dip Galvanized Bolts - LongZe | Corrosion Resistance, Industrial Applications

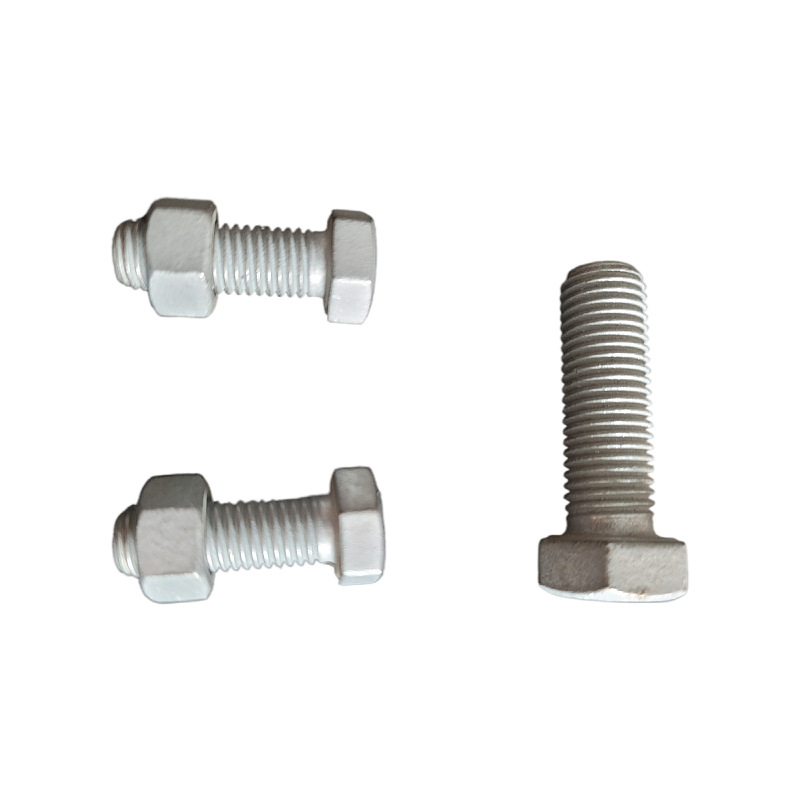

Hot dip galvanized bolts are critical components in modern engineering, offering exceptional corrosion resistance and mechanical strength. This article provides an in-depth analysis of hot dip galvanized bolts, their technical specifications, applications, and the company behind this innovative product line. The information is structured to meet the needs of engineers, procurement professionals, and industrial buyers seeking reliable fastening solutions.

Product Overview

Hot dip galvanized bolts are manufactured using a specialized process that immerses steel components in molten zinc, creating a durable protective layer. This coating not only enhances corrosion resistance but also improves the bolts' longevity in harsh environments. The product range includes various types such as Grade 8.8 hex bolts, carbon steel hex bolts, and stainless steel hex bolts, catering to diverse industrial requirements.

Key Features and Advantages

1. Superior Corrosion Resistance

The hot dip galvanizing process creates a metallurgical bond between the zinc coating and the steel substrate, forming a robust barrier against environmental elements. This makes the bolts ideal for outdoor applications, marine environments, and industrial settings where exposure to moisture and chemicals is common.

2. High Mechanical Strength

Available in multiple grades (4.8, 5.8, 6.8, 8.8, 10.9), these bolts offer exceptional tensile strength. The Grade 8.8 variant, for instance, has a minimum tensile strength of 830 MPa, making it suitable for heavy-duty applications in construction, automotive, and machinery industries.

3. Versatile Applications

The bolts are compatible with a wide range of standards, including ISO, DIN, ANSI, and ASTM. This ensures compatibility with global engineering practices, reducing the need for custom solutions.

Technical Specifications

| Parameter | Details |

|---|---|

| Material | Q235, 35K, 45K, 40Cr, B7, 20MnTiB, A2, A4, Carbon Steel, Stainless Steel |

| Grade | 4.8, 5.8, 6.8, 8.8, 10.9 |

| Surface Finish | BZP, HDG, BLACK, DACROMET, TEFLON, YZP, Plain, Black Oxide, Zinc Plated |

| Size Range | M6-M60 (1/4"-2.5") |

| Length Range | 40mm-6000mm (Customizable) |

| Standards Compliance | ISO, DIN, ANSI, ASME, ASTM, BS, AS, JIS, DIN933, DIN931, ISO 4017, EN 24017, Metric, Inch |

Applications in Industrial and Construction Sectors

Hot dip galvanized bolts are extensively used in the following industries:

- Construction: For structural steel connections, scaffolding, and bridge components.

- Marine: In shipbuilding and offshore platforms where corrosion resistance is critical.

- Automotive: For vehicle assembly and heavy machinery parts.

- Renewable Energy: In wind turbine towers and solar panel mounting systems.

- Infrastructure: For utility poles, fencing, and road signage.

Company Background: Hebei Longze Metal Products Manufacturing Co., Ltd.

Founded with a commitment to quality and innovation, Hebei Longze Metal Products Manufacturing Co., Ltd. (English name: About LongZe) has established itself as a leading supplier of fasteners. The company's expertise in types of bolts and types of screws and bolts ensures that their products meet international standards. Their facilities are equipped with advanced manufacturing technologies, enabling the production of high-quality galvanized bolts that comply with global specifications.

LongZe's dedication to customer satisfaction is reflected in its customizable solutions for hot dipped galvanized screws and hot dipped galvanized carriage bolts, catering to niche market demands.

Standards and Compliance

The bolts adhere to multiple international standards, ensuring their reliability and interoperability. Key standards include:

- ISO 4017: Metric hex bolts with coarse thread.

- DIN 933: Hexagon bolts with fine thread.

- ASTM A307: General-purpose carbon steel bolts.

- EN 24017: European standard for metric hex bolts.

Compliance with these standards is verified through rigorous quality control processes, as highlighted by the National Institute of Standards and Technology (NIST) guidelines on material testing and certification.

Conclusion

Hot dip galvanized bolts from Hebei Longze Metal Products Manufacturing Co., Ltd. represent a blend of advanced technology and industrial expertise. Their robust design, compliance with international standards, and versatility make them indispensable in modern engineering. Whether for construction, marine, or automotive applications, these bolts deliver exceptional performance and durability. For more information, visit the company's product page or explore their company profile.

References

1. National Institute of Standards and Technology (NIST). Retrieved from https://www.nist.gov/

Latest news

-

High-Strength Hot Dip Galvanized Bolts-About LongZe|Corrosion Resistance, Global Standards

NewsAug.07,2025

-

High-Strength Hot Dip Galvanized Bolts - LongZe | Corrosion Resistance, Industrial Applications

NewsAug.07,2025

-

Premium 12mm Anchor Fastener for Strong & Secure Fixtures

NewsAug.07,2025

-

Hot Dip Galvanized Bolts - LongZe | Corrosion Resistance, High Strength

NewsAug.07,2025

-

High-Strength Hot Dip Galvanized Bolts - LongZe | Corrosion Resistance, Customization

NewsAug.06,2025

-

High-Strength Hot Dip Galvanized Bolts - LongZe Metal Products | Corrosion Resistance, Customization

NewsAug.06,2025