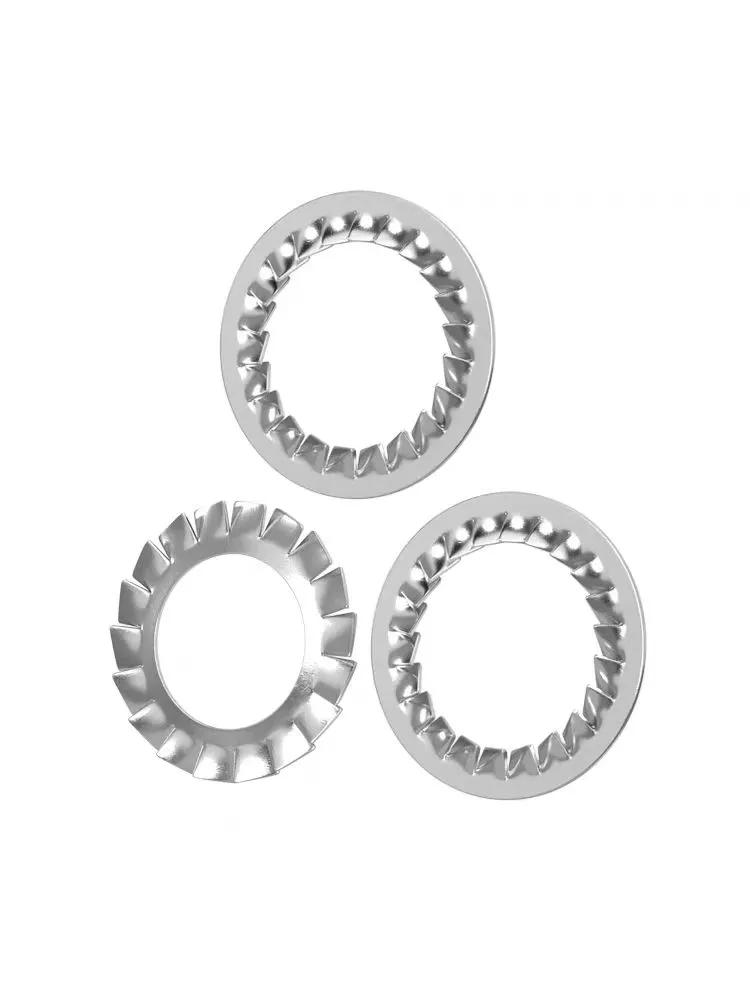

assorted steel washers

Jan . 25, 2025 22:40 Back to list

assorted steel washers

Assorted steel washers play a crucial role in a myriad of applications, from everyday DIY projects to complex engineering constructs. They are often perceived as unremarkable components, yet their functionality, material choice, and design intricacies underpin much of the mechanical integrity we rely upon daily.

Comparing assorted steel washers with alternatives like rubber or plastic reveals the strengths of steel in prominence. While non-metal washers can be useful in minimizing vibrations and providing a tight seal, they lack the hardness and temperature resistance inherent to steel, making them unsuitable for high-stress environments. Thus, understanding the distinct advantages of steel washers, in contrast to alternatives, is fundamental when making an informed choice about which type to use. Another critical factor is the ease of availability and customization options. Many suppliers offer assorted ranges that cater to both small-scale hobbyists and industrial clients. This ensures that no matter the complexity of your project, the correct size and type of washer can be sourced efficiently. Custom steel washers are also an option for specifications beyond standard measurements. An expert craftsman or engineer will attest to the importance of sourcing washers from reputable suppliers. Assured quality and material authenticity reinforce the dependability of steel washers, reducing risks associated with inferior components. In essence, while often overlooked, assorted steel washers are integral to the integrity and longevity of mechanical assemblies. Their role in enhancing the distribution of forces cannot be understated, providing essential support across various industries. By leveraging the robust properties of steel and the diverse types of washers available, professionals can ensure the success and safety of their projects, leaving no room for mechanical compromise.

Comparing assorted steel washers with alternatives like rubber or plastic reveals the strengths of steel in prominence. While non-metal washers can be useful in minimizing vibrations and providing a tight seal, they lack the hardness and temperature resistance inherent to steel, making them unsuitable for high-stress environments. Thus, understanding the distinct advantages of steel washers, in contrast to alternatives, is fundamental when making an informed choice about which type to use. Another critical factor is the ease of availability and customization options. Many suppliers offer assorted ranges that cater to both small-scale hobbyists and industrial clients. This ensures that no matter the complexity of your project, the correct size and type of washer can be sourced efficiently. Custom steel washers are also an option for specifications beyond standard measurements. An expert craftsman or engineer will attest to the importance of sourcing washers from reputable suppliers. Assured quality and material authenticity reinforce the dependability of steel washers, reducing risks associated with inferior components. In essence, while often overlooked, assorted steel washers are integral to the integrity and longevity of mechanical assemblies. Their role in enhancing the distribution of forces cannot be understated, providing essential support across various industries. By leveraging the robust properties of steel and the diverse types of washers available, professionals can ensure the success and safety of their projects, leaving no room for mechanical compromise.

Next:

Latest news

-

Hot Dip Galvanized Bolts - Hebei Longze | High Strength, Corrosion Resistance

NewsAug.01,2025

-

High-Strength Hot Dip Galvanized Bolts - LongZe | Corrosion Resistance, Custom Sizes

NewsAug.01,2025

-

Best Self Tapping Screws for Drywall - Fast & Secure Installation

NewsJul.31,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&Customization

NewsJul.31,2025

-

Hot Dip Galvanized Bolts-Hebei Longze Metal Products|Corrosion Resistance&High Strength

NewsJul.31,2025

-

Hot Dip Galvanized Bolts-About LongZe|High Strength, Corrosion Resistance

NewsJul.30,2025