solar panel mounting hardware

our own factory

Hardware for Solar Panels samples are free

Description

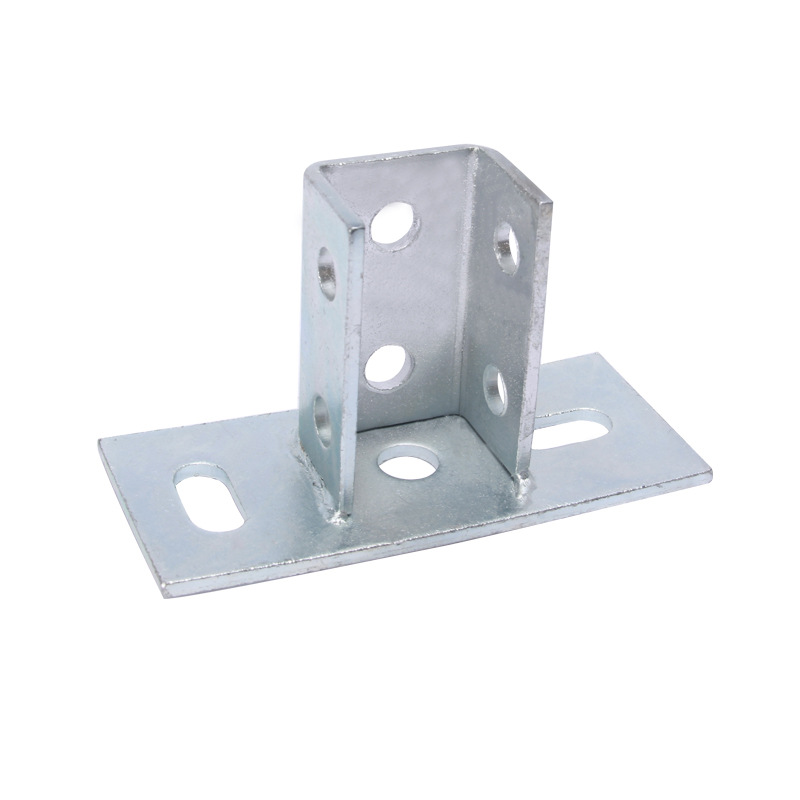

When preparing a traditional base, the sleeve 10 and the base plate 20 need to be prepared separately first, and then the lower end of the sleeve 10 is welded to the middle position of the upper surface of the base plate 20. Obviously, such a preparation method is cumbersome, time-consuming, and labor-intensive, and during precise installation, the weld seam 30 will also affect the assembly, and the solar panel roof mounts and welding smoke during the welding process will cause varying degrees of harm to the human body. The preparation is easy, the cost is low, and the harm to the human body is small. The welding-free photovoltaic bracket base, including the casing formed by bending the steel plate, does not require frequent replacement of fixing devices, which increases production efficiency. At the same time, the fixing effect is good and will not cause the photovoltaic modules to fall during welding. It will not cause damage to photovoltaic modules, and greatly improve the welding efficiency of photovoltaic modules.

solar panel mounting hardware, solar brackets, solar mounting brackets, solar panel brackets, Solar Panel Mounting Brackets, solar panel mounts, solar panel roof mounts

40/ 50/ 70mm

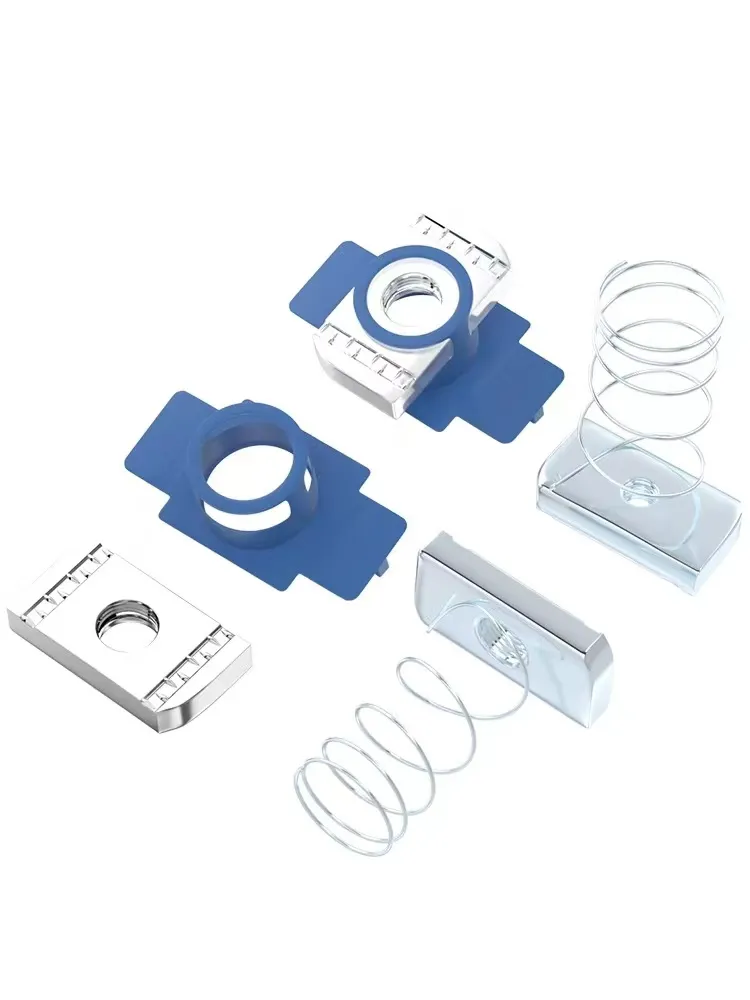

ISO / DIN / ANSI / ASME / ASTM / BS / AS / JIS

Q235 / 35K / 45K / 40Cr / B7 / 20MnTiB / A2 / A4 carbon steel Solar Panel Mount Bracket & stainless steel Solar Panel Mounting

BZP / YZP / DACROMET / TEFLON or customizable, black solar panel mounting hardware, zinc plated, brass solar panel mounting hardware, Plain solar panel mounting hardware, Hot dip galvanizing solar panel mounting hardware, HDG solar panel mounting hardware