High-Strength Hot Dip Galvanized Bolts - LongZe Metal Products

8월 . 16, 2025 05:20 Back to list

High-Strength Hot Dip Galvanized Bolts - LongZe Metal Products

Introduction to Hot Dip Galvanized Bolts

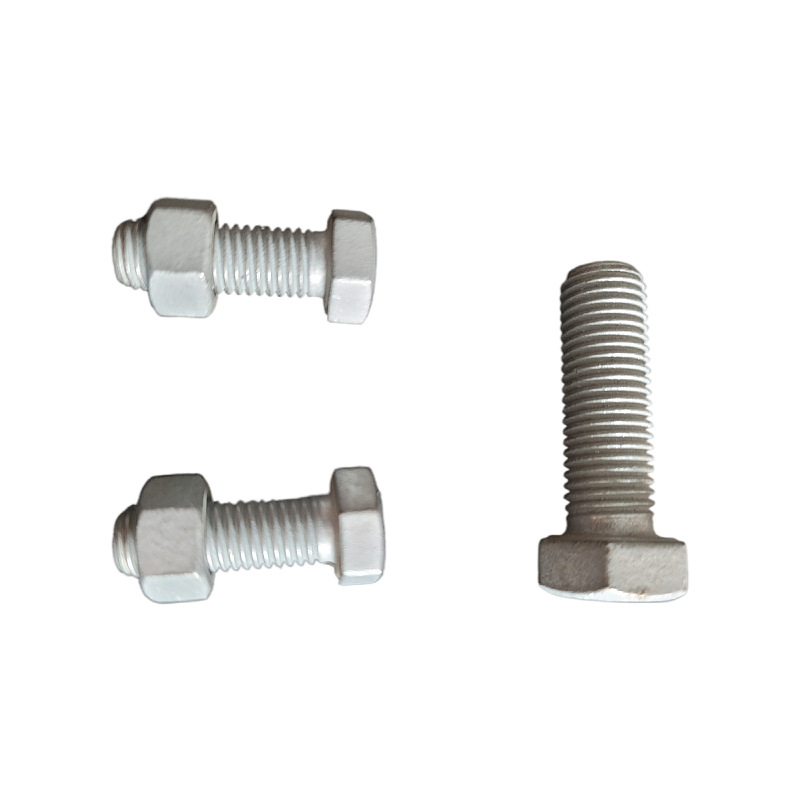

Hot dip galvanized bolts are a critical component in construction, manufacturing, and infrastructure projects. These fasteners combine the strength of high-grade steel with the corrosion-resistant properties of a zinc coating, ensuring longevity and reliability in even the harshest environments. LongZe Metal Products, a leading manufacturer in China, offers a comprehensive range of hot dip galvanized bolts tailored to meet international standards.

Product Features and Advantages

LongZe's hot dip galvanized bolts are engineered to deliver exceptional performance across diverse applications. Key features include:

- High Strength: Available in grades 4.8, 5.8, 6.8, 8.8, and 10.9, these bolts are designed to withstand heavy loads and extreme stress.

- Corrosion Resistance: The hot dip galvanizing process provides a durable zinc coating that protects against rust and environmental degradation.

- Customization: Sizes and lengths can be tailored to meet specific project requirements, with options ranging from M6 to M60 and lengths up to 6000mm.

- Compliance: Adherence to international standards such as ISO, DIN, ANSI, and ASTM ensures compatibility with global engineering practices.

Technical Specifications

| Parameter | Details |

|---|---|

| Material | Carbon steel (Q235, 35K, 45K, 40Cr, 20MnTiB) and stainless steel |

| Grade | 4.8, 5.8, 6.8, 8.8, 10.9 |

| Surface Treatment | Hot dip galvanizing, black oxide, zinc plating, DACROMET, and more |

| Size Range | M6-M60 (1/4"–2.5") |

| Length Options | 40mm–6000mm (customizable) |

| Standards | ISO 4017, DIN 933, DIN 931, ANSI, ASME, ASTM, and more |

Applications in Industrial and Construction Sectors

LongZe's hot dip galvanized bolts are widely used in:

- Infrastructure: Bridges, highways, and railway systems where durability is paramount.

- Industrial Machinery: Heavy equipment and structures requiring high tensile strength.

- Marine Engineering: Offshore platforms and ships exposed to saltwater corrosion.

- Renewable Energy: Wind turbines and solar panel installations that demand long-term reliability.

These bolts are also ideal for anchor bolt applications in concrete structures, ensuring secure and lasting connections.

Company Background: LongZe Metal Products

Founded in 2005, LongZe Metal Products has established itself as a trusted manufacturer of high-quality fasteners. Based in Hebei, China, the company specializes in producing hot dip galvanized bolts, screws, and anchor bolts. With over 15 years of experience, LongZe adheres to strict quality control measures to meet global standards.

LongZe's commitment to innovation and customer satisfaction is reflected in its extensive product range and competitive pricing. The company serves clients across industries, including construction, automotive, and energy, ensuring that its products meet the highest performance benchmarks.

Why Choose LongZe's Hot Dip Galvanized Bolts?

Several factors make LongZe a preferred choice for hot dip galvanized bolts:

- Expertise: A team of skilled engineers and technicians ensures precision in every product.

- Quality Assurance: Rigorous testing and compliance with international standards guarantee reliability.

- Custom Solutions: Tailored specifications to suit unique project requirements.

- Global Reach: Exporting to over 50 countries, LongZe provides seamless international service.

Industry Standards and Certifications

LongZe's products comply with major international standards, including:

- ISO 4017: Metric hexagon bolts with coarse pitch threads.

- DIN 933: Hexagon bolts with a fine pitch for precision applications.

- ANSI/ASME: Standards for American and international engineering practices.

- ASTM A307: Specifications for carbon steel bolts in general applications.

These certifications ensure that LongZe's bolts are compatible with global manufacturing and construction processes.

Environmental and Safety Considerations

LongZe prioritizes sustainability and safety in its production processes. The hot dip galvanizing method not only enhances corrosion resistance but also reduces the need for frequent replacements, minimizing environmental impact. Additionally, the company adheres to NIST guidelines for material testing and quality control, ensuring that its products meet rigorous safety standards.

Conclusion

LongZe Metal Products' hot dip galvanized bolts combine cutting-edge technology with robust engineering to deliver unmatched performance. Whether for industrial machinery, infrastructure projects, or marine applications, these fasteners are designed to withstand the test of time. With a focus on quality, customization, and compliance, LongZe continues to set the benchmark for hot dip galvanized bolts in the global market.

This is the last article

Latest news

-

High-Strength Hot Dip Galvanized Bolts - LongZe Metal Products

NewsAug.16,2025

-

Elegant Flower Baskets - Fresh Floral Gifts & Delivery

NewsAug.16,2025

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Customization

NewsAug.16,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance|Customization

NewsAug.15,2025

-

High-Strength Hot Dip Galvanized Bolts-LongZe|Corrosion Resistance&Customizable Sizes

NewsAug.15,2025

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Customization

NewsAug.15,2025