High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance,High Strength

8月 . 17, 2025 03:15 Back to list

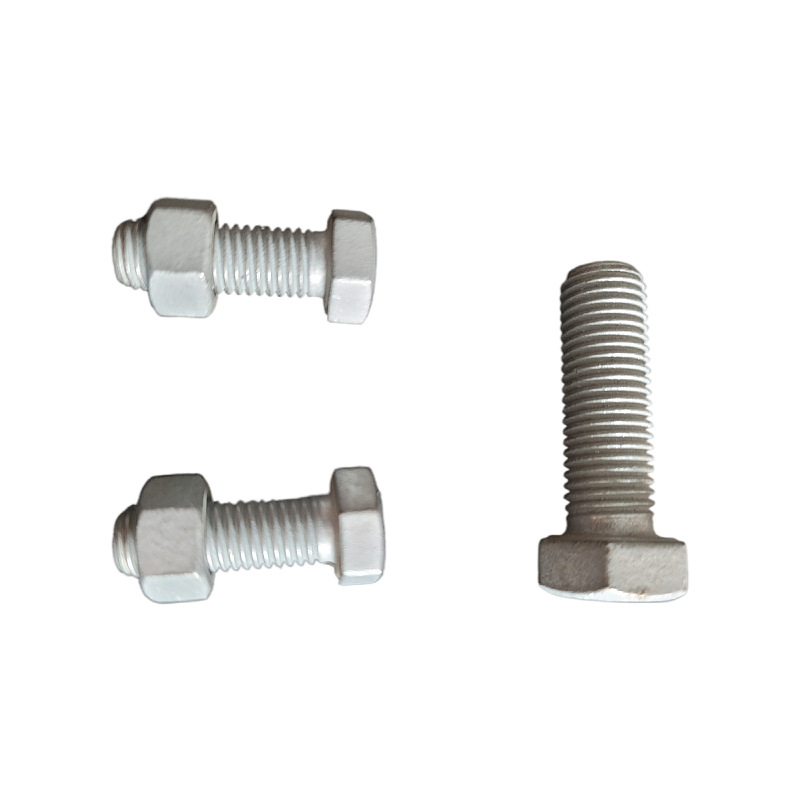

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance,High Strength

Hot dip galvanized bolts are essential components in modern industrial and construction applications, offering exceptional durability and corrosion resistance. This article provides an in-depth analysis of the Hot Dip Galvanized Bolts produced by Hebei Longze Metal Products Manufacturing Co., Ltd., highlighting their technical specifications, applications, and industry relevance.

Product Overview

The Hot Dip Galvanized Bolts are designed to meet the demands of high-strength and corrosion-resistant environments. These bolts are available in multiple grades, including 4.8, 5.8, 6.8, 8.8, and 10.9, catering to a wide range of industrial applications. The product is manufactured using carbon steel and stainless steel materials, ensuring robust performance under varying conditions.

Key features of these bolts include:

- High Strength: Available in grades up to 10.9, providing exceptional load-bearing capacity.

- Corrosion Resistance: Hot dip galvanization offers a durable zinc coating that protects against rust and environmental degradation.

- Customization: Sizes and lengths can be tailored to specific project requirements.

- Compliance: Adheres to international standards such as ISO, DIN, ANSI, and ASME.

Technical Specifications

The Hot Dip Galvanized Bolts are available in a wide range of sizes and lengths, making them suitable for diverse applications. Below is a detailed specification table:

| Parameter | Details |

|---|---|

| Material | Q235, 35K, 45K, 40Cr, B7, 20MnTiB, A2, A4 (carbon steel and stainless steel) |

| Grade | 4.8, 5.8, 6.8, 8.8, 10.9 |

| Size Range | M6-M60 (1/4"-2-1/2") |

| Length Range | 40mm-6000mm (customizable) |

| Standards | ISO, DIN, ANSI, ASME, ASTM, BS, AS, JIS, DIN933, DIN931, ISO 4017, EN 24017 |

| Surface Treatment | Hot dip galvanizing, black oxide, zinc plating, DACROMET, TEFLON, and others |

Applications and Use Cases

These high-strength bolts are widely used in various industries due to their reliability and performance. Key applications include:

- Construction: Structural steel connections, bridges, and high-rise buildings.

- Manufacturing: Heavy machinery, automotive components, and industrial equipment.

- Infrastructure: Road and rail systems, utility poles, and outdoor structures.

- Marine: Corrosion-resistant fasteners for boats, docks, and offshore platforms.

The Hot Dip Galvanized Bolts are particularly suited for environments exposed to moisture, chemicals, and extreme weather conditions. Their zinc coating provides long-term protection, reducing maintenance costs and extending service life.

Company Background: Hebei Longze Metal Products Manufacturing Co., Ltd.

Hebei Longze Metal Products Manufacturing Co., Ltd. is a leading manufacturer of high-quality fasteners, specializing in hot dip galvanized bolts and other industrial components. With years of experience in the industry, the company adheres to strict quality control measures to ensure compliance with international standards.

Hebei Longze's commitment to innovation and customer satisfaction has established it as a trusted supplier for clients worldwide. The company's state-of-the-art production facilities and advanced testing equipment enable it to deliver products that meet the highest standards of performance and durability.

Industry Standards and Compliance

The Hot Dip Galvanized Bolts are manufactured in accordance with global standards, ensuring compatibility and reliability across different applications. Key standards include:

- ISO: International Organization for Standardization, ensuring quality and safety.

- DIN: German Industrial Standards, widely recognized in Europe.

- ANSI: American National Standards Institute, for U.S. market compliance.

- ASME: American Society of Mechanical Engineers, for mechanical components.

These standards guarantee that the bolts meet rigorous requirements for strength, dimensional accuracy, and corrosion resistance, making them suitable for critical applications.

Environmental and Safety Considerations

The hot dip galvanization process used for these bolts provides a protective zinc layer that significantly enhances their resistance to corrosion. This coating is particularly beneficial in environments where exposure to moisture and chemicals is inevitable. According to the National Institute of Standards and Technology (NIST), corrosion protection is a critical factor in extending the lifespan of structural components and reducing maintenance costs (NIST Reference).

Additionally, the company ensures that its production processes comply with environmental regulations, minimizing the ecological footprint of its operations.

Conclusion

The Hot Dip Galvanized Bolts from Hebei Longze Metal Products Manufacturing Co., Ltd. represent a reliable and durable solution for a wide range of industrial and construction applications. With their high strength, corrosion resistance, and compliance with international standards, these bolts are an ideal choice for projects requiring long-term performance and reliability.

For more information about the product or to explore other fastener solutions, visit the Hebei Longze Metal Products Manufacturing Co., Ltd. website or contact their customer support team.

References

National Institute of Standards and Technology (NIST). (n.d.). Corrosion Protection Standards. Retrieved from https://www.nist.gov.

Latest news

-

Hot Dip Galvanized Bolts-Hebei Longze|High-Strength Corrosion Resistance

NewsAug.17,2025

-

High-Strength Hot Dip Galvanized Bolts-LongZe|Corrosion Resistance, High Strength

NewsAug.17,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance,High Strength

NewsAug.17,2025

-

Premium Blind Fasteners for Strong, Hidden, One-Sided Joints

NewsAug.17,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | High Strength, Corrosion Resistance

NewsAug.17,2025

-

High-Strength Hot Dip Galvanized Bolts - LongZe Metal Products

NewsAug.16,2025