High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Customization

আগস্ট . 06, 2025 05:20 Back to list

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Customization

Introduction to Hot Dip Galvanized Bolts

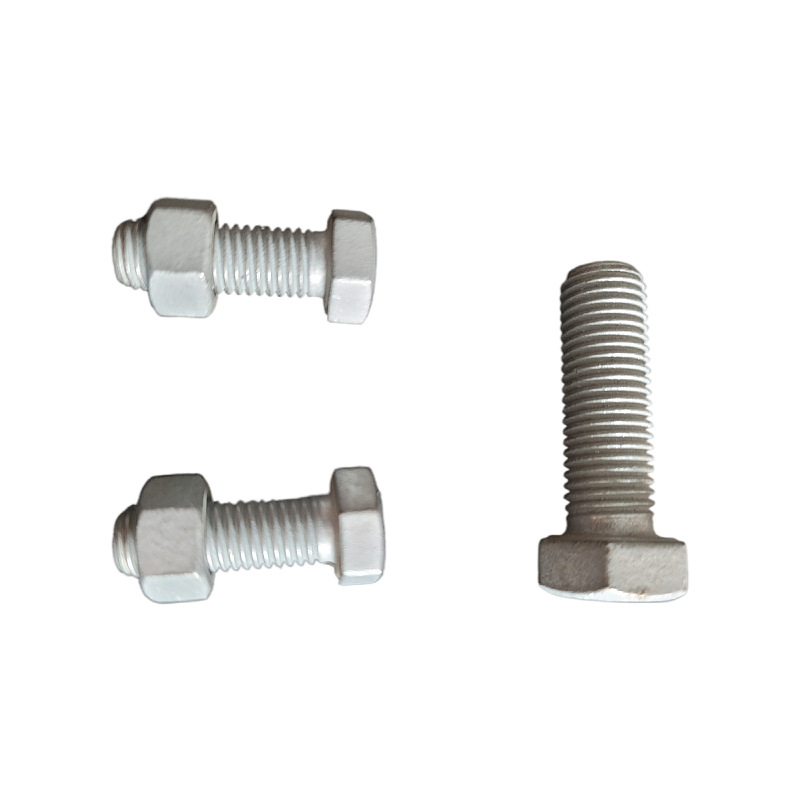

Hot dip galvanized bolts are essential components in modern engineering and construction, offering exceptional strength and corrosion resistance. These fasteners are manufactured using a process where steel is submerged in molten zinc, creating a durable, protective coating. This method ensures longevity, even in harsh environments. The hot dip galvanized bolts produced by Hebei Longze Metal Products Manufacturing Co., Ltd. exemplify this technology, combining high-quality materials with advanced manufacturing techniques.

The hot dip galvanized bolts are designed to meet international standards such as ISO, DIN, and ASTM. Their robust construction makes them ideal for applications ranging from infrastructure projects to heavy machinery. This article delves into the features, specifications, and applications of these bolts, highlighting their role in modern engineering.

Key Features and Advantages

The hot dip galvanized bolts from Hebei Longze are engineered to deliver superior performance. Here are some of their standout features:

- High Strength: Available in grades 4.8, 5.8, 6.8, 8.8, and 10.9, these bolts provide exceptional tensile strength, making them suitable for high-stress applications.

- Corrosion Resistance: The hot dip galvanization process coats the bolts with a thick layer of zinc, protecting them from rust and environmental degradation. This is particularly beneficial in coastal or industrial settings.

- Wide Range of Sizes and Lengths: The bolts are available in sizes from M6 to M60 and lengths ranging from 40mm to 6000mm, offering flexibility for diverse projects.

- Compliance with International Standards: Adherence to standards like ISO 4017, DIN 933, and ASTM A307 ensures reliability and compatibility with global engineering practices.

- Customization Options: Clients can request tailored solutions, including specific surface treatments like black oxide or Teflon coatings.

The hot dip galvanized bolts are also known for their durability in extreme conditions. According to the National Institute of Standards and Technology (NIST), "Zinc coatings provide a sacrificial barrier that significantly enhances the lifespan of steel components in corrosive environments" (NIST, 2023). This makes them a preferred choice for critical infrastructure projects.

Technical Specifications

The hot dip galvanized bolts are available in a variety of materials, grades, and finishes. Below is a detailed specification table:

| Parameter | Details |

|---|---|

| Material | Carbon steel (Q235, 35K, 45K, 40Cr, 20MnTiB), stainless steel (A2, A4) |

| Grade | 4.8, 5.8, 6.8, 8.8, 10.9 |

| Surface Treatment | Hot dip galvanizing (HDG), Black oxide, Zinc plating, Teflon, DACROMET |

| Standards | ISO, DIN, ANSI, ASME, ASTM, BS, JIS, EN 24017 |

| Size Range | M6 to M60 (1/4" to 2.5") |

| Length Range | 40mm to 6000mm (customizable) |

The hot dip galvanized bolts are designed to meet the rigorous demands of industrial applications. Their specifications ensure compatibility with a wide range of machinery and structures, from automotive components to large-scale construction projects.

Applications and Use Cases

The versatility of hot dip galvanized bolts makes them suitable for various industries. Key applications include:

- Infrastructure: Used in bridges, highways, and utility poles due to their resistance to environmental corrosion.

- Construction: Ideal for steel frames, roofing, and structural connections where durability is critical.

- Marine Industry: Their zinc coating protects against saltwater corrosion, making them ideal for shipbuilding and offshore platforms.

- Automotive: Employed in vehicle chassis and engine components for high-strength fastening.

- Energy Sector: Used in wind turbines, solar panels, and power transmission systems.

According to NIST, "Galvanized steel fasteners are widely used in critical infrastructure due to their ability to withstand extreme weather conditions and reduce maintenance costs" (NIST, 2023). This underscores their importance in modern engineering.

Company Background: Hebei Longze Metal Products Manufacturing Co., Ltd.

Hebei Longze Metal Products Manufacturing Co., Ltd. is a leading manufacturer of high-quality fasteners, specializing in hot dip galvanized bolts and related products. With decades of experience, the company has established itself as a reliable supplier to industries worldwide. Their commitment to innovation, quality control, and customer satisfaction has earned them a strong reputation in the market.

As a company focused on About LongZe, Hebei Longze adheres to strict production standards and invests heavily in research and development. Their state-of-the-art facilities ensure that every product meets international quality benchmarks. The company's dedication to sustainability is also evident in their eco-friendly manufacturing processes.

Conclusion

The hot dip galvanized bolts from Hebei Longze Metal Products Manufacturing Co., Ltd. represent the pinnacle of engineering excellence. Their combination of strength, durability, and corrosion resistance makes them indispensable in modern construction and industrial applications. Whether for infrastructure projects, marine environments, or automotive systems, these bolts offer a reliable solution for demanding conditions.

For more information about hot dip galvanized bolts or to explore other products, visit About LongZe.

Latest news

-

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, High Strength

NewsAug.06,2025

-

Secure SS Quick Release Bumper Fasteners | Top Quality

NewsAug.06,2025

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Customization

NewsAug.06,2025

-

High-Strength Hot Dip Galvanized Bolts - LongZe Metal Products Co., Ltd.|Corrosion Resistance&Durability

NewsAug.06,2025

-

Hot Dip Galvanized Bolts - LongZe | High Strength, Corrosion Resistance

NewsAug.05,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance, High Strength

NewsAug.05,2025