High-Strength Hot Dip Galvanized Bolts - LongZe Metal Products Co., Ltd.|Corrosion Resistance&Durability

Aug . 06, 2025 03:15 Back to list

High-Strength Hot Dip Galvanized Bolts - LongZe Metal Products Co., Ltd.|Corrosion Resistance&Durability

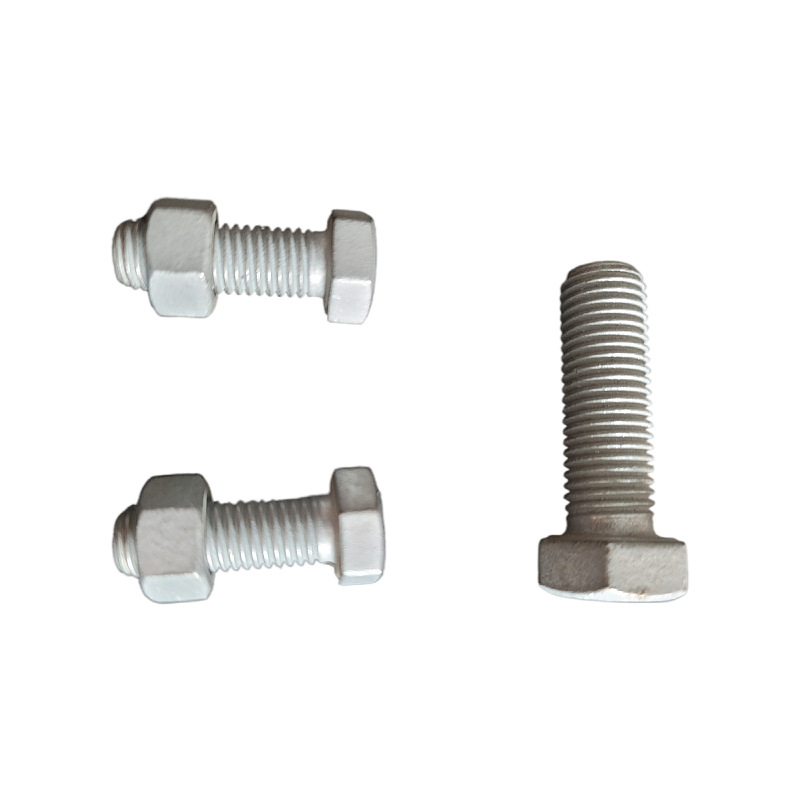

Hot dip galvanized bolts are essential fasteners in modern engineering and construction, offering exceptional strength, corrosion resistance, and durability. This article provides an in-depth analysis of the Hot Dip Galvanized Bolts product line, covering its features, technical specifications, applications, and the company behind it. Whether you're a manufacturer, engineer, or procurement professional, this guide will help you understand the value of these critical components.

Product Overview

Hot dip galvanized bolts are designed to withstand harsh environmental conditions while maintaining structural integrity. The Hot Dip Galvanized Bolts offered by 河北隆泽金属制品制造有限公司 (LongZe Metal Products Co., Ltd.) are manufactured to meet international standards and are available in a wide range of sizes, grades, and materials. These bolts are ideal for applications requiring high strength and long-term performance in corrosive environments.

Key Features and Advantages

1. Exceptional Strength and Durability

The Hot Dip Galvanized Bolts are manufactured using high-grade materials such as carbon steel and stainless steel, with grades ranging from 4.8 to 10.9. This ensures they can withstand heavy loads and extreme conditions. The galvanization process adds a protective zinc coating, enhancing their resistance to rust and corrosion.

2. Corrosion Resistance

Hot dip galvanizing involves immersing the bolts in molten zinc, creating a robust protective layer that prevents oxidation. This makes the Hot Dip Galvanized Bolts ideal for outdoor and marine applications. According to the National Institute of Standards and Technology (NIST), galvanized coatings significantly extend the lifespan of steel components in corrosive environments (NIST, 2025).

3. Versatile Applications

These bolts are suitable for a wide range of industries, including construction, automotive, infrastructure, and industrial machinery. Their compatibility with international standards like ISO, DIN, and ASTM ensures they can be integrated into global projects seamlessly.

Technical Specifications

| Category | Details |

|---|---|

| Size | M6-M60, 1/4"-2-1/2" (customizable) |

| Length | 40mm-6000mm (customizable) |

| Standards | ISO, DIN, ANSI, ASME, ASTM, BS, AS, JIS, DIN933, DIN931, ISO 4017, EN 24017 |

| Materials | Q235, 35K, 45K, 40Cr, B7, 20MnTiB, A2, A4, carbon steel, stainless steel |

| Grades | 4.8, 5.8, 6.8, 8.8, 10.9 |

| Surface Treatments | BZP, HDG, BLACK, DACROMET, TEFLON, YZP, Plain, Black Oxide, Zinc Plated, Hot Dip Galvanizing |

Applications in Modern Engineering

The Hot Dip Galvanized Bolts are widely used in critical applications where reliability is paramount. For example:

- Construction: Used in steel structures, bridges, and high-rise buildings to ensure long-term stability.

- Automotive: Employed in vehicle frames and components requiring corrosion resistance.

- Infrastructure: Ideal for road signs, utility poles, and coastal structures exposed to harsh weather.

- Industrial Machinery: Applied in heavy equipment and machinery that operates in corrosive environments.

About the Manufacturer: 河北隆泽金属制品制造有限公司

河北隆泽金属制品制造有限公司 (LongZe Metal Products Co., Ltd.) is a leading manufacturer of high-quality fasteners, specializing in galvanized bolts, nuts, and washers. With years of experience in the industry, the company adheres to strict quality control measures and international standards to deliver products that meet global demands. Their commitment to innovation and customer satisfaction has made them a trusted partner for businesses worldwide.

Why Choose Hot Dip Galvanized Bolts?

Compared to other fasteners, hot dip galvanized bolts offer several advantages:

- Longevity: The zinc coating provides decades of protection against rust and corrosion.

- Cost-Effectiveness: Their durability reduces the need for frequent replacements, saving long-term costs.

- Compatibility: Available in multiple standards and sizes, making them suitable for diverse projects.

Conclusion

The Hot Dip Galvanized Bolts from 河北隆泽金属制品制造有限公司 represent a perfect blend of strength, durability, and corrosion resistance. Whether you're working on a large-scale construction project or a specialized industrial application, these bolts are designed to meet the highest standards of performance. By choosing this product, you ensure reliability and longevity for your projects.

References

National Institute of Standards and Technology (NIST). (2025). Corrosion Resistance of Galvanized Steel. Retrieved from https://www.nist.gov

Disclaimer: This article is for informational purposes only. For detailed specifications, please refer to the official Hot Dip Galvanized Bolts product page.

Latest news

-

Secure SS Quick Release Bumper Fasteners | Top Quality

NewsAug.06,2025

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Customization

NewsAug.06,2025

-

High-Strength Hot Dip Galvanized Bolts - LongZe Metal Products Co., Ltd.|Corrosion Resistance&Durability

NewsAug.06,2025

-

Hot Dip Galvanized Bolts - LongZe | High Strength, Corrosion Resistance

NewsAug.05,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance, High Strength

NewsAug.05,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|High Strength&Corrosion Resistance

NewsAug.05,2025