self tapping screws for plastic

Th12 . 04, 2024 09:05 Back to list

self tapping screws for plastic

Self-Tapping Screws for Plastic The Essential Guide

When it comes to fastening materials, self-tapping screws have become a staple in various applications, especially for plastic. These screws are engineered to create their own threads in the material they are driven into, providing a secure and reliable fastening solution. In this article, we will explore the features, benefits, and best practices for using self-tapping screws in plastic applications.

Understanding Self-Tapping Screws

Self-tapping screws are unique in their design; they possess a sharp point and threads that can cut into plastic materials without the need for a pre-drilled hole. This characteristic not only simplifies the installation process but also ensures a strong hold by anchoring the screw tightly within the material.

There are two primary types of self-tapping screws used for plastics thread-forming and thread-cutting screws. Thread-forming screws create a molded thread in the plastic, displacing the material to ensure a snug fit, while thread-cutting screws remove material to create threads. Choosing the right type depends on the specific plastic's properties and the application requirements.

Benefits of Using Self-Tapping Screws in Plastic

1. Ease of Installation Self-tapping screws are easy to install since they do not require additional tools for hole preparation. This saves time and labor during assembly.

2. Strong Connection When properly installed, self-tapping screws form a robust connection with plastic materials. The threads grip securely, providing resistance against pull-out and torque.

3. Versatility These screws are suitable for various plastic types, including PVC, polyethylene, polypropylene, and acrylic. This versatility makes them ideal for industries ranging from automotive to electronics, and home improvement.

4. Cost-Effective By eliminating the need for pre-drilling and additional fasteners, self-tapping screws can reduce overall project costs. This makes them a popular choice in both large-scale manufacturing and DIY projects.

self tapping screws for plastic

5. Reduced Risk of Cracking Unlike traditional screws, self-tapping screws are designed to minimize stress on the surrounding plastic. This is critical, as excessive stress can lead to cracking or weakening of the material.

Best Practices for Using Self-Tapping Screws in Plastic

To ensure optimal performance when using self-tapping screws in plastic, consider the following best practices

1. Choose the Right Screw Size Select the appropriate screw diameter and length for your application. The size should be adequate to provide enough grip without compromising the integrity of the plastic.

2. Consider the Plastic Type Different plastics have different properties, such as hardness and flexibility. Assess these properties to choose the right screw type (thread-forming or thread-cutting) and material (such as zinc-plated steel or stainless steel) for your needs.

3. Control Torque Use a torque-controlled driver to avoid over-tightening, which can strip the threads or damage the plastic. It’s crucial to apply enough force to secure the screw while being cautious not to apply excessive torque.

4. Pilot Holes for Thick Materials For thicker plastic components, creating a pilot hole may enhance installation ease and prevent potential cracking. This pre-drilling should be done with care, maintaining a suitable diameter that allows the self-tapping screw to form threads effectively.

5. Test the Setup Before final assembly, it’s beneficial to conduct test installations. This will help confirm the suitability of the selected screws and ensure that they meet the desired performance expectations.

Conclusion

Self-tapping screws for plastic applications represent an innovative and efficient fastening solution. By understanding their design, benefits, and best practices for installation, users can achieve secure and lasting connections in their projects. Whether you are a professional or a DIY enthusiast, incorporating self-tapping screws into your toolkit can greatly enhance your ability to work with plastic materials effectively.

Latest news

-

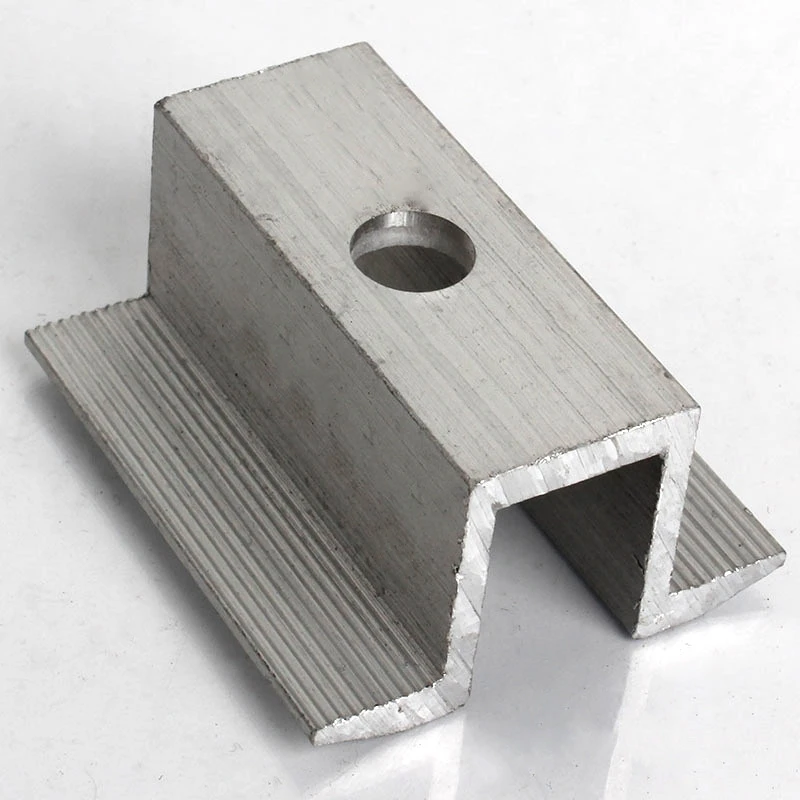

MS Slotted Channel Fasteners Durable, Pre-Galvanized Mild Steel

NewsApr.29,2025

-

High-Strength Self Tapping Screws for Cast Iron Fast Installation & Durability

NewsApr.29,2025

-

Mild Steel Slotted Channel & Fasteners - Durable, Adjustable Solutions

NewsApr.28,2025

-

ISO Spring Washer - Secure, Durable Fastener with ISO Compliance ISO Spring Washer

NewsApr.28,2025

-

Mild Steel Stud Bolt Fasteners - High Strength & Corrosion Resistant

NewsApr.28,2025

-

M6x45 Shear Bolt - High-Strength Safety Fastener

NewsApr.28,2025