Innovative Techniques for Creating Flat Sided Washers in Precision Engineering Applications

Th7 . 23, 2024 15:37 Back to list

Innovative Techniques for Creating Flat Sided Washers in Precision Engineering Applications

The Concept of Flat-Sided Washers An Overview

In the world of mechanical engineering and manufacturing, flat-sided washers play a crucial role in fastening applications. While they may seem like simple components, their design and function are essential in ensuring the stability and reliability of various structures and machines. This article delves into the concept of flat-sided washers, their applications, benefits, and considerations.

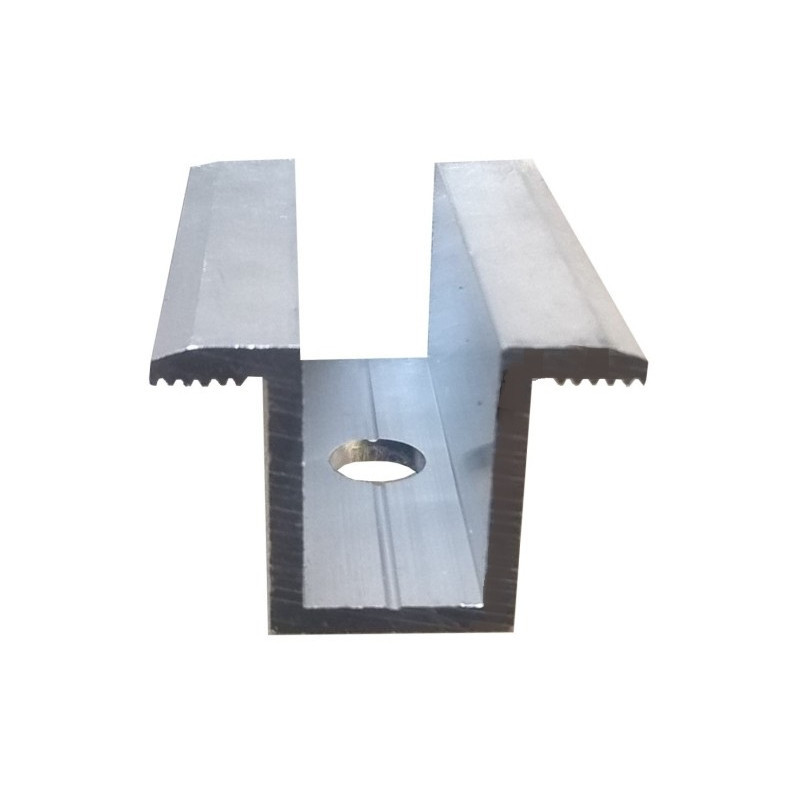

What is a Flat-Sided Washer?

A flat-sided washer is a disc-shaped piece of material with a center hole, designed to be placed under the head of a fastener or nut. Unlike their traditional round counterparts, flat-sided washers feature flat edges, which provide a unique profile. This design offers distinct advantages when it comes to load distribution and stability.

Applications

Flat-sided washers are commonly used in a variety of industries, including construction, automotive, aerospace, and manufacturing. Their applications can be broadly categorized into

1. Load Distribution By providing a larger surface area, flat-sided washers help to distribute the load of a fastener across a wider area. This is particularly important in applications where the material might deform under pressure.

2. Prevention of Damage These washers serve to prevent damage to the surfaces being fastened. For example, when a bolt is tightened, the washer acts as a cushion, reducing the risk of marring or crushing the material.

3. Alignment In some cases, flat-sided washers assist in aligning components. Their shape can guide the positioning of fasteners, ensuring that parts fit together correctly without shifting.

4. Vibration Resistance Flat-sided washers can also improve resistance to vibrations. When used in conjunction with locking nuts, they help maintain tension in a fastened joint, preventing loosening over time.

Material Considerations

flat sided washer

The choice of material for flat-sided washers is critical, as it affects their performance. Common materials include

- Steel Typically used for its strength and durability. Galvanized or stainless steel options offer resistance to corrosion. - Plastic For applications requiring electrical insulation or chemical resistance. - Bronze Often used in marine applications due to its resistance to corrosion.

Choosing the right material depends on the specific application and the environmental factors involved, such as exposure to moisture or chemicals

.Benefits of Using Flat-Sided Washers

1. Enhanced Stability The flat edges provide better stability, particularly in applications that experience fluctuating loads.

2. Improved Performance By distributing load evenly, these washers help to maintain the integrity of the structure, thus improving overall performance and lifespan.

3. Low Maintenance Once properly installed, flat-sided washers typically require little to no maintenance, making them an efficient choice for long-term applications.

4. Versatility Available in various sizes and materials, flat-sided washers can be used in countless environments and conditions.

Conclusion

Flat-sided washers may be small components, but their significance in various applications cannot be understated. By providing load distribution, protecting surfaces, enhancing vibration resistance, and improving alignment, they contribute to the safety and durability of mechanical assemblies. As industries evolve and engineering demands increase, the design and application of flat-sided washers will continue to play a vital role. Understanding their importance is crucial for engineers, manufacturers, and anyone involved in assembling components, ensuring that the systems they work on remain reliable and efficient.

Latest news

-

Best Self Tapping Screws for Drywall - Fast & Secure Installation

NewsJul.31,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&Customization

NewsJul.31,2025

-

Hot Dip Galvanized Bolts-Hebei Longze Metal Products|Corrosion Resistance&High Strength

NewsJul.31,2025

-

Hot Dip Galvanized Bolts-About LongZe|High Strength, Corrosion Resistance

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Customization

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025