High-Quality M16 Nylon Washers for Durable and Reliable Applications in Industrial Projects

Th8 . 12, 2024 12:02 Back to list

High-Quality M16 Nylon Washers for Durable and Reliable Applications in Industrial Projects

Understanding M16 Nylon Washers Essential Components for Various Applications

When it comes to mechanical engineering and assembly, small components can have a significant impact on the overall functionality and durability of a system. One such component is the M16 nylon washer, a seemingly simple but vital part that serves various purposes in numerous applications.

What are M16 Nylon Washers?

M16 nylon washers are circular disks made from nylon, with a nominal diameter of 16mm, typically designed to fit M16 bolts or screws. They are part of a larger category of washers that include materials like metal and rubber, but nylon offers unique properties that make it an excellent choice for many scenarios.

Nylon is a synthetic polymer known for its strength, flexibility, and resistance to wear and tear. As a flexible material, nylon washers can absorb vibrations, distribute loads evenly, and provide insulation against electricity, which is particularly beneficial in electrical applications.

Key Characteristics of M16 Nylon Washers

1. Corrosion Resistance Unlike metal washers, nylon washers are resistant to corrosion, making them ideal for use in chemicals, moisture-prone environments, or outdoors where they could be exposed to the elements. This property extends the lifespan of any assembly or structure that employs them.

2. Lightweight Being lighter than traditional metal washers, nylon washers do not add significant weight to the assembly. This quality is particularly advantageous in industries where weight reduction is crucial, such as in aerospace and automotive applications.

3. Electrical Insulation Nylon is a non-conductive material, which allows these washers to be used in electrical applications without the risk of short-circuiting or other electrical failures. This characteristic is crucial for securing electrical components while ensuring safety.

4. Vibration Dampening The flexible nature of nylon helps to absorb vibrations and shocks. This is particularly important in applications where machinery or vehicles might experience significant movement during operation, thus preventing loosening of threaded connections.

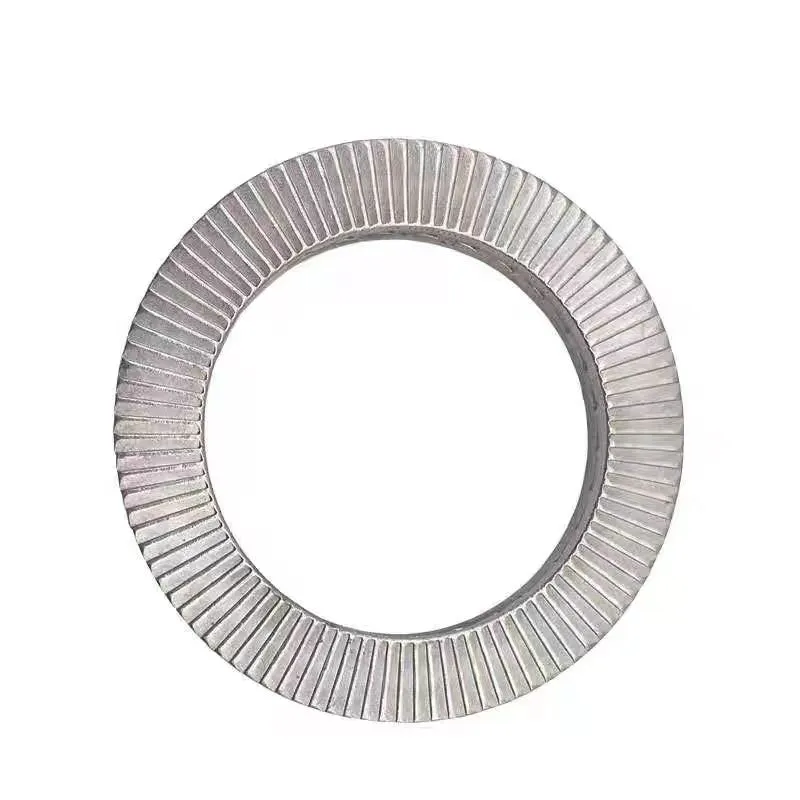

m16 nylon washers

Applications of M16 Nylon Washers

M16 nylon washers find their relevance in various sectors, including

- Automotive Industry Used in assembling engines, suspensions, and various other parts to provide a secure fit and prevent corrosion. - Aerospace Essential for securing components in aircraft where weight and resilience to environmental factors are critical. - Electrical Engineering Used to insulate electrical connections and secure components against vibrations without conducting electricity.

- Manufacturing and Assembly Employed broadly in machinery where they help reduce wear and provide a smooth surface contact between components.

Installation and Usage Tips

When installing M16 nylon washers, it is essential to ensure they are placed correctly to serve their intended function. They should be positioned between the nut and the surface being fastened to distribute the load properly. Additionally, the surface on which the nylon washer is applied should be clean and free of debris to ensure a proper seal and fit.

Correct torque specifications should also be followed during installation to prevent damages to the nylon material, which can deform if excessively tightened.

Conclusion

M16 nylon washers may seem like minor components, but their benefits significantly enhance the performance and longevity of various assemblies. With properties such as corrosion resistance, lightweight nature, electrical insulation, and vibration dampening, they play an essential role in a wide range of industrial applications. Understanding their characteristics and proper usage can greatly contribute to the success of mechanical engineering projects and ensure reliability in performance across many fields.

Latest news

-

Hot Dip Galvanized Bolts-About LongZe|High Strength, Corrosion Resistance

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Customization

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

High-Strength Hot-Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, High Strength

NewsJul.30,2025