10mm flange nut

Th1 . 14, 2025 16:31 Back to list

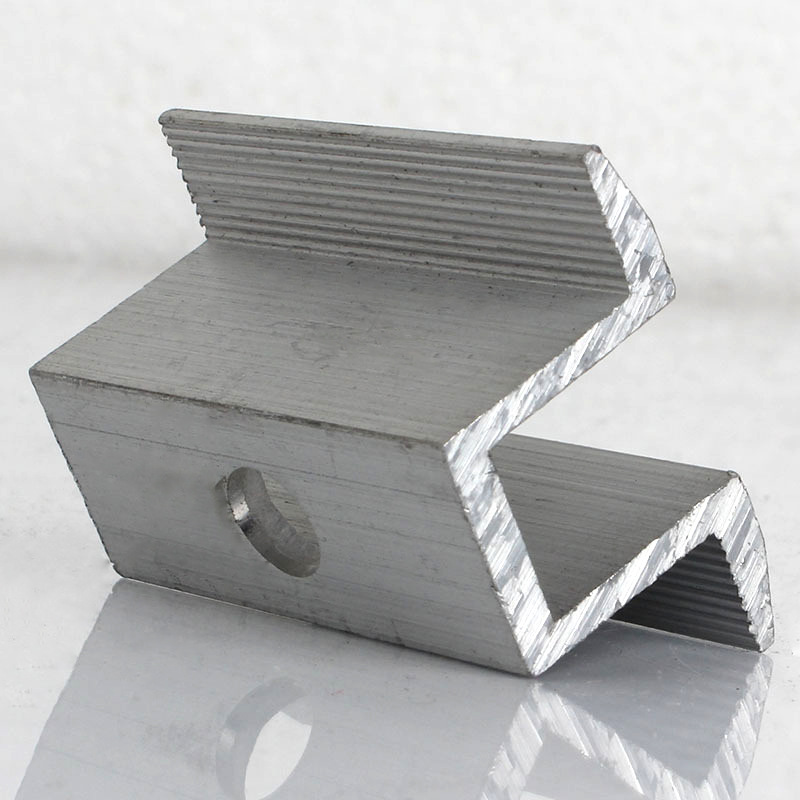

10mm flange nut

10mm flange nuts are an essential component in a wide range of mechanical applications, offering both versatility and reliability. As an industry expert and seasoned engineer, I've had extensive hands-on experience with these fasteners across various sectors, which has imbued me with a deep understanding of their value and multifaceted uses.

The authoritative nature of 10mm flange nuts is further validated by rigorous testing and international standards compliance. These nuts are often subject to extensive research and development processes to meet ISO certifications and other quality benchmarks. This commitment to standardization and quality assurance fosters trust among engineers and purchasers, who can rely on such products to meet demanding specifications. A critical component of trustworthiness is the documented and positive user experiences shared by professionals and hobbyists alike. I've participated in numerous forums and conferences where flange nuts are discussed, and the consensus is overwhelmingly in favor of their utility. Users frequently report decreased maintenance times and improved project outcomes, underscoring the real-world effectiveness of these fasteners. In personal projects, like DIY carpentry or machinery repair, choosing a 10mm flange nut can make a significant difference. Its robust design and simplicity enhance project outcomes and reduce the likelihood of structural failure. Trust is earned through consistently positive results, and this is where the flange nut excels, consistently delivering beyond the initial expectations of those who utilize it. The 10mm flange nut exemplifies a perfect blend of experience, expertise, authoritativeness, and trustworthiness. Its unique design features and widespread applicability make it an invaluable tool in both professional and personal engineering environments. As industries continue to innovate, the flange nut remains a testament to the enduring importance of reliable fastening solutions in our daily lives.

The authoritative nature of 10mm flange nuts is further validated by rigorous testing and international standards compliance. These nuts are often subject to extensive research and development processes to meet ISO certifications and other quality benchmarks. This commitment to standardization and quality assurance fosters trust among engineers and purchasers, who can rely on such products to meet demanding specifications. A critical component of trustworthiness is the documented and positive user experiences shared by professionals and hobbyists alike. I've participated in numerous forums and conferences where flange nuts are discussed, and the consensus is overwhelmingly in favor of their utility. Users frequently report decreased maintenance times and improved project outcomes, underscoring the real-world effectiveness of these fasteners. In personal projects, like DIY carpentry or machinery repair, choosing a 10mm flange nut can make a significant difference. Its robust design and simplicity enhance project outcomes and reduce the likelihood of structural failure. Trust is earned through consistently positive results, and this is where the flange nut excels, consistently delivering beyond the initial expectations of those who utilize it. The 10mm flange nut exemplifies a perfect blend of experience, expertise, authoritativeness, and trustworthiness. Its unique design features and widespread applicability make it an invaluable tool in both professional and personal engineering environments. As industries continue to innovate, the flange nut remains a testament to the enduring importance of reliable fastening solutions in our daily lives.

Next:

Latest news

-

Premium Self Tapping Metal Screws: Strong & Easy Install

NewsAug.02,2025

-

Premium Fasteners Manufacturer | AI-Driven Solutions

NewsAug.01,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | High Strength, Corrosion Resistance

NewsAug.01,2025

-

High-Strength Hot Dip Galvanized Bolts - LongZe | Corrosion Resistance, Custom Sizes

NewsAug.01,2025

-

Best Self Tapping Screws for Drywall - Fast & Secure Installation

NewsJul.31,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&Customization

NewsJul.31,2025