Understanding 3 8 x 24 Flange Nut Specifications and Applications for Industrial Use

اگست . 15, 2024 04:38 Back to list

Understanding 3 8 x 24 Flange Nut Specifications and Applications for Industrial Use

Understanding the 3 8 x 24 Flange Nut A Key Component in Fastening Technology

In the vast world of mechanical engineering, the choice of fastening components plays a critical role in ensuring the reliability and integrity of assembled structures. Among these components, the flange nut stands out due to its versatility and effectiveness in various applications. In particular, the 3 8 x 24 flange nut exemplifies specific industry standards and applications that are essential for engineers and manufacturers.

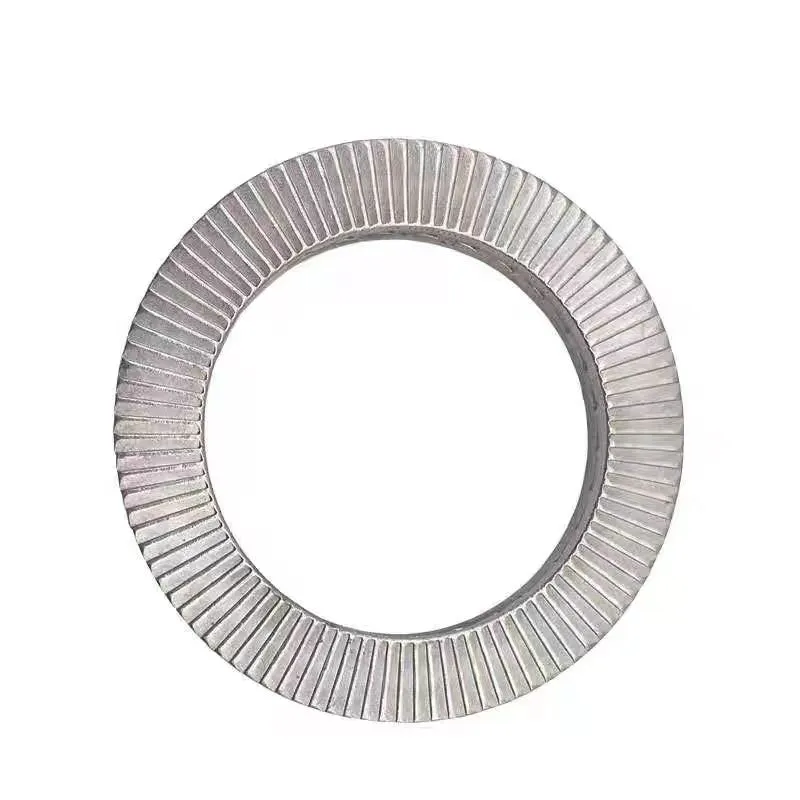

What is a Flange Nut?

A flange nut is a type of nut that features a wide flange at one end. This flange serves a dual purpose it acts as a washer and provides a larger surface area for load distribution, which helps to prevent the nut from loosening during operation. The design of the flange nut allows it to maintain a secure grip on the bolt or screw while also minimizing the risk of damage to the materials being joined.

Specifications of the 3 8 x 24 Flange Nut

The designation of the 3 8 x 24 flange nut provides important information regarding its specifications. The 3% often indicates the material specification, hinting at an alloy composition or treatment process that confers specific mechanical properties to the nut. This could involve enhanced corrosion resistance or improved hardness, which are critical in high-stress environments.

The 208% suggests particular standards that may relate to the dimensions of the nut or its compatibility with various bolt types. When combined with the x 24 measurement, it typically refers to the diameter and thread pitch, which in this case would indicate that the nut is designed to fit a bolt with a diameter of 24mm. An understanding of these specifications is crucial for engineers when selecting the appropriate fastening components for their projects.

3 8 x 24 flange nut

Applications of the 3 8 x 24 Flange Nut

The flange nut, particularly in the specification of 3 8 x 24, finds applications across numerous industries. In automotive manufacturing, for example, the precision and reliability of fastening components are paramount. Flange nuts provide the necessary strength to withstand vibrations and stresses experienced by vehicles over time. This is essential not only for the performance of the vehicle but also for the safety of its occupants.

In the construction sector, the use of flange nuts in structural steel applications affords a solid connection that can handle significant loads. The wider surface area of the flange helps distribute weight and reduces the potential for failure in joints, which is particularly important in high-rise buildings and bridges.

Furthermore, in aerospace applications, where weight savings are critical, the use of specialized flange nuts helps achieve robust connections without adding unnecessary weight. Here, the material specification and design of the 3 8 x 24 flange nut can significantly influence the performance and efficiency of an aircraft.

Conclusion

In summary, the 3 8 x 24 flange nut is a vital component in the realm of fastening technology. Its design, specifications, and applications underline the importance of selecting the right fastening solutions for specific engineering challenges. As industries continue to evolve, the demand for reliable and effective fastening components will only increase, solidifying the role of flange nuts as fundamental elements in engineering and manufacturing processes. Understanding these components is essential for any engineer or manufacturer aiming to optimize their designs for safety, performance, and longevity.

Latest news

-

Hot Dip Galvanized Bolts-About LongZe|High Strength, Corrosion Resistance

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Customization

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

High-Strength Hot-Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, High Strength

NewsJul.30,2025