Exploring Various Types of T Bolts and Their Applications in Industry

نومبر . 01, 2024 00:01 Back to list

Exploring Various Types of T Bolts and Their Applications in Industry

Understanding the Different Types of T Bolts

T bolts, often referred to as T-slot bolts, are a crucial component in various fastening applications. Their unique design allows for versatility in assembly and provides a secure connection in both light and heavy-duty applications. Understanding the different types of T bolts can help you choose the right one for your project, ensuring optimal performance and reliability.

What Are T Bolts?

T bolts are specialty fasteners with a T-shaped head that allows them to slide into a T-slot, typically found in aluminum extrusions. This design enables easy adjustment and repositioning of components, making them a favorite in manufacturing and engineering settings.

Types of T Bolts

1. Standard T Bolts Standard T bolts are the most common type and are widely used in various applications. They come with a straight T-shaped head that fits securely into T-slots. These bolts are often made from materials such as steel or stainless steel, providing strength and durability. They are available in various sizes and lengths to accommodate different projects.

2. Heavy-Duty T Bolts Designed for more demanding applications, heavy-duty T bolts are thicker and wider than standard ones. They can withstand higher loads and are typically used in industrial equipment, machinery, and construction applications. Heavy-duty T bolts often have a robust finish, such as black oxide or zinc plating, to enhance corrosion resistance.

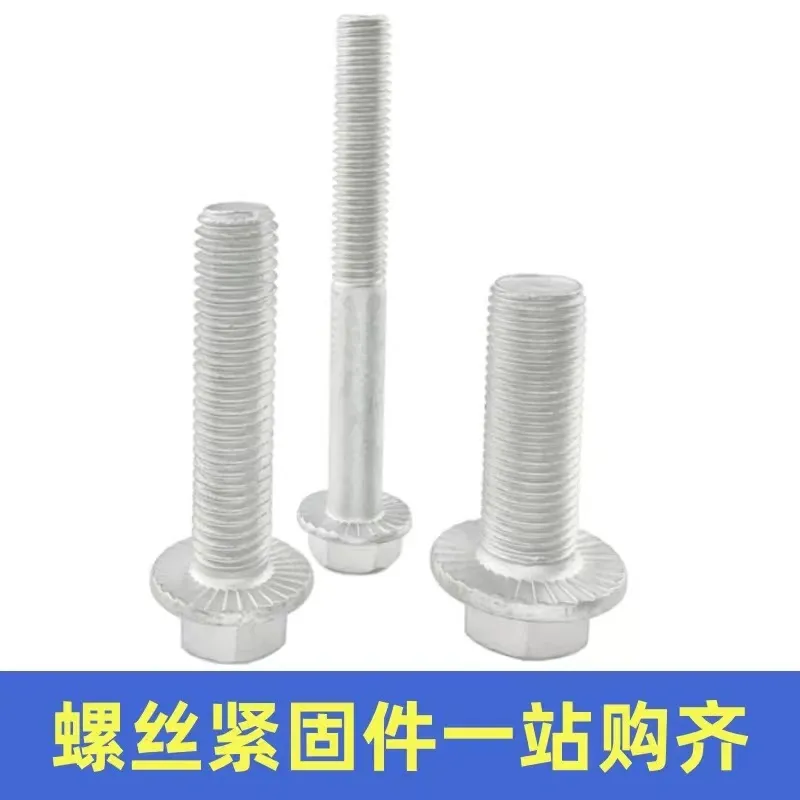

3. Flanged T Bolts Flanged T bolts feature a flat, flange on the head that provides a larger bearing surface, distributing the load over a wider area. This design is beneficial for applications where the bolt needs to be tightened down without the risk of pulling through the material. Flanged T bolts are commonly used in woodworking, metal fabrication, and assembly line processes.

types of t bolts

4. Sliding T Bolts Sliding T bolts are designed with a unique feature that allows them to be adjusted horizontally within the T-slot. This flexibility makes them ideal for applications requiring fine-tuning or adjustments after initial assembly. These bolts are often used in framing systems and modular assembly setups.

5. Shoulder T Bolts Shoulder T bolts have a cylindrical shoulder that creates a fixed distance for components to be held apart. This design is useful for spacers or where precise alignment is required. They are commonly employed in automotive and aerospace applications where exacting specifications are critical.

Applications of T Bolts

T bolts are popular in various industries, including manufacturing, construction, automotive, and furniture assembly. Their adaptability allows them to be used in a wide range of applications, from securing parts in machinery to assembling frames and structures.

In furniture making, T bolts provide a strong joint that can be disassembled easily if necessary. In the context of automotive engineering, they secure components together while allowing for vibrations and thermal expansion.

Conclusion

Choosing the right type of T bolt is essential for the success of your project. By understanding the different types available, such as standard, heavy-duty, flanged, sliding, and shoulder T bolts, you can make informed decisions tailored to your specific needs. Investing time in selecting appropriate fasteners will lead to more durable, reliable assemblies and systems. Whether in industrial settings or DIY projects, T bolts are an indispensable element in modern construction and manufacturing processes.

Latest news

-

Premium Fasteners Manufacturer | AI-Driven Solutions

NewsAug.01,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | High Strength, Corrosion Resistance

NewsAug.01,2025

-

High-Strength Hot Dip Galvanized Bolts - LongZe | Corrosion Resistance, Custom Sizes

NewsAug.01,2025

-

Best Self Tapping Screws for Drywall - Fast & Secure Installation

NewsJul.31,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&Customization

NewsJul.31,2025

-

Hot Dip Galvanized Bolts-Hebei Longze Metal Products|Corrosion Resistance&High Strength

NewsJul.31,2025