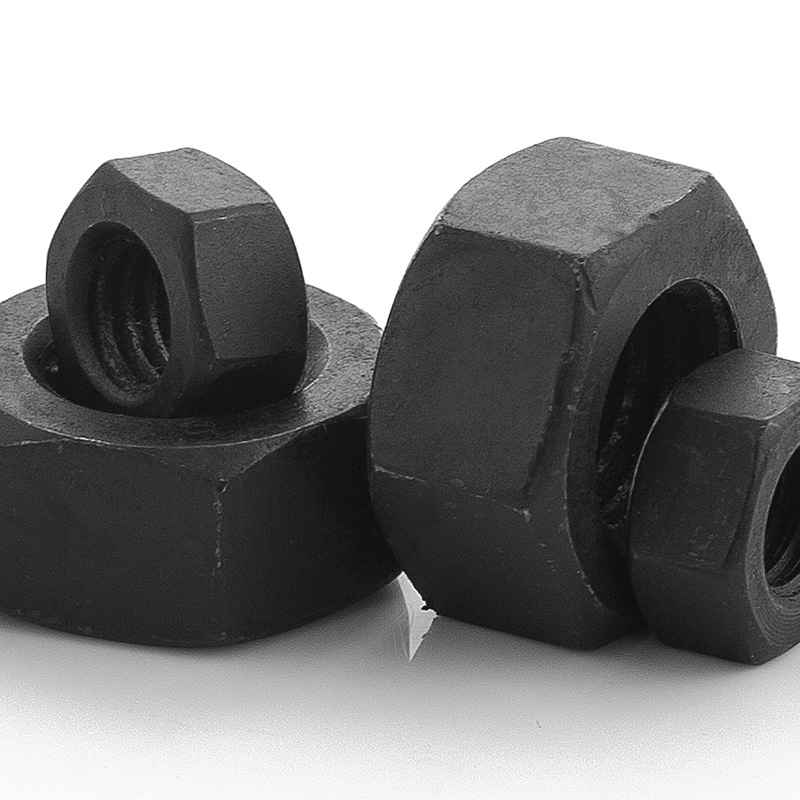

swivel flange nut

جنوری . 17, 2025 00:47 Back to list

swivel flange nut

Unlocking the Full Potential of Swivel Flange Nuts A Comprehensive Guide

Expertise within the field emphasizes the installation precision of swivel flange nuts. Proper alignment ensures optimal performance. When torque is applied, the swivel mechanism allows for minor adjustments, compensating for any misalignment that may have occurred during setup. This flexibility serves as a cornerstone for complex assemblies, reducing installation time and improving safety by minimizing the risk of over-tightening. Moreover, leveraging torque tools specifically designed for swivel flange nuts can further augment fastening accuracy, thereby extending the lifecycle of the assembly. Authoritativeness stems from the adaptability and compliance of swivel flange nuts with existing industry standards. Certified to meet DIN or ISO specifications, these nuts meet stringent requirements, ensuring that they uphold quality and safety measures across different geographical markets. Industry leaders in aerospace and mechanical engineering continually rely on tested and certified swivel flange nuts, underscoring their role as reliable components in high-stakes environments. Furthermore, manufacturers are tasked with consistent quality checks to maintain the integrity of production, a process crucial in establishing and maintaining industry trust. The trustworthiness of swivel flange nuts also pivots on transparency and thoroughness in documentation. Manufacturers who provide detailed installation guidelines, coupled with thorough testing certifications, offer end-users confidence in their products. This transparency is critical as it enables users to make informed decisions, promoting safe usage practices in line with best industry standards. Additionally, case studies showcasing success stories from large infrastructure projects or demanding automotive applications provide potential assurances to new customers exploring swivel flange nuts for their needs. Navigating through the complexities of mechanical design and installation necessitates a reliable partner in fastening technology—swivel flange nuts deliver just that. Recognizing their pivotal role, seasoned professionals and industry newcomers alike can benefit from an in-depth understanding of these components. By focusing on material suitability, proper installation techniques, compliance with industry standards, and transparent communication from manufacturers, users can unlock the full potential of swivel flange nuts, ensuring robust, efficient, and safe assemblies across a wide spectrum of applications. With technologies and engineering concepts continually evolving, swivel flange nuts remain at the forefront, offering innovative solutions for modern mechanical challenges.

Expertise within the field emphasizes the installation precision of swivel flange nuts. Proper alignment ensures optimal performance. When torque is applied, the swivel mechanism allows for minor adjustments, compensating for any misalignment that may have occurred during setup. This flexibility serves as a cornerstone for complex assemblies, reducing installation time and improving safety by minimizing the risk of over-tightening. Moreover, leveraging torque tools specifically designed for swivel flange nuts can further augment fastening accuracy, thereby extending the lifecycle of the assembly. Authoritativeness stems from the adaptability and compliance of swivel flange nuts with existing industry standards. Certified to meet DIN or ISO specifications, these nuts meet stringent requirements, ensuring that they uphold quality and safety measures across different geographical markets. Industry leaders in aerospace and mechanical engineering continually rely on tested and certified swivel flange nuts, underscoring their role as reliable components in high-stakes environments. Furthermore, manufacturers are tasked with consistent quality checks to maintain the integrity of production, a process crucial in establishing and maintaining industry trust. The trustworthiness of swivel flange nuts also pivots on transparency and thoroughness in documentation. Manufacturers who provide detailed installation guidelines, coupled with thorough testing certifications, offer end-users confidence in their products. This transparency is critical as it enables users to make informed decisions, promoting safe usage practices in line with best industry standards. Additionally, case studies showcasing success stories from large infrastructure projects or demanding automotive applications provide potential assurances to new customers exploring swivel flange nuts for their needs. Navigating through the complexities of mechanical design and installation necessitates a reliable partner in fastening technology—swivel flange nuts deliver just that. Recognizing their pivotal role, seasoned professionals and industry newcomers alike can benefit from an in-depth understanding of these components. By focusing on material suitability, proper installation techniques, compliance with industry standards, and transparent communication from manufacturers, users can unlock the full potential of swivel flange nuts, ensuring robust, efficient, and safe assemblies across a wide spectrum of applications. With technologies and engineering concepts continually evolving, swivel flange nuts remain at the forefront, offering innovative solutions for modern mechanical challenges.

Next:

Latest news

-

Premium Fasteners Manufacturer | AI-Driven Solutions

NewsAug.01,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | High Strength, Corrosion Resistance

NewsAug.01,2025

-

High-Strength Hot Dip Galvanized Bolts - LongZe | Corrosion Resistance, Custom Sizes

NewsAug.01,2025

-

Best Self Tapping Screws for Drywall - Fast & Secure Installation

NewsJul.31,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&Customization

NewsJul.31,2025

-

Hot Dip Galvanized Bolts-Hebei Longze Metal Products|Corrosion Resistance&High Strength

NewsJul.31,2025