self tapping metal screws for aluminum

نومبر . 03, 2024 19:47 Back to list

self tapping metal screws for aluminum

Self-Tapping Metal Screws for Aluminum A Comprehensive Guide

Self-tapping metal screws are an invaluable tool in modern construction and manufacturing, especially when working with materials like aluminum. These screws offer several advantages, including efficiency, reliability, and ease of use. In this article, we will explore the characteristics, benefits, and proper application of self-tapping screws designed specifically for aluminum.

Understanding Self-Tapping Screws

Self-tapping screws are fasteners that create their own hole while being driven into the material. Unlike regular screws that require a pre-drilled hole, self-tapping screws are designed with a specialized point that allows them to cut through various materials, including metal. This feature not only speeds up the installation process but also provides a more secure fit, reducing the likelihood of loosening over time.

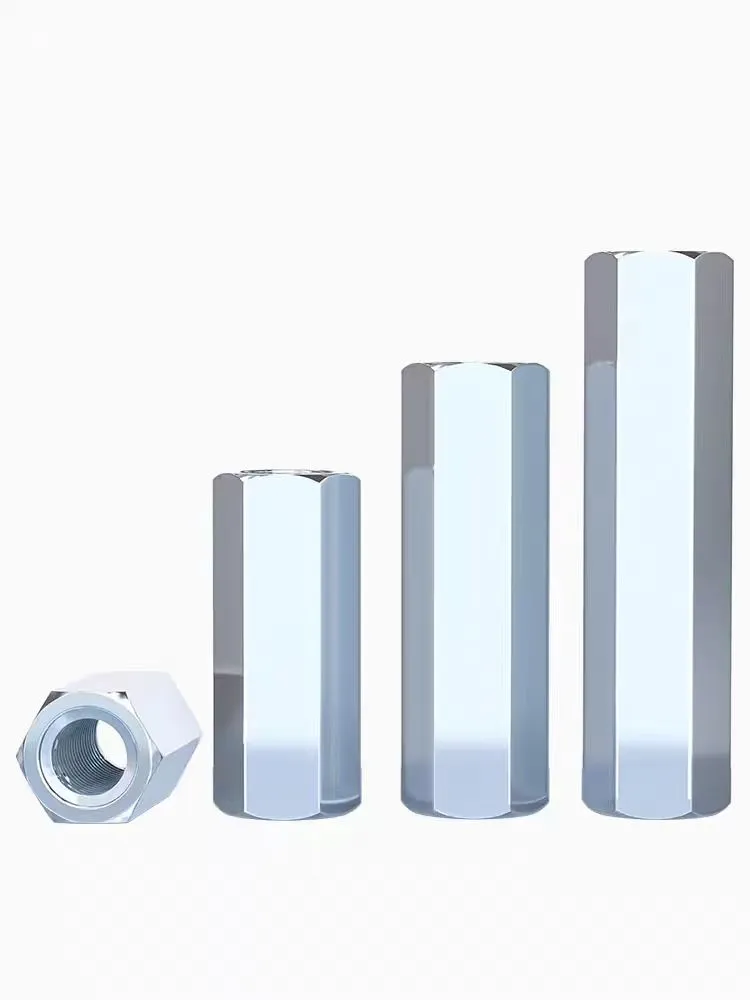

Types of Self-Tapping Screws for Aluminum

When it comes to aluminum, it is essential to choose the right type of self-tapping screw. There are two primary types

1. Thread-Cutting Screws These screws have sharp threads that cut into the aluminum as they are driven in. They create a strong bond and are ideal for thicker materials.

2. Thread-Forming Screws Unlike thread-cutting screws, thread-forming screws displace aluminum material to form threads instead of cutting it. These are particularly useful for softer aluminum and provide a tight fit without the risk of shavings.

Benefits of Using Self-Tapping Screws for Aluminum

1. Time Efficiency Because they do not require pre-drilling, self-tapping screws save significant time during installation. This feature is particularly advantageous in large-scale projects or situations where time constraints are in place.

self tapping metal screws for aluminum

2. Cost-Effectiveness Although self-tapping screws may have a slightly higher upfront cost compared to traditional screws, the savings in labor and time often outweigh these expenses in projects with high workloads.

3. Versatility Self-tapping screws can be used in a variety of applications beyond aluminum, including plastics and wood. This versatility makes them a valuable addition to any toolbox.

4. Stronghold When installed correctly, self-tapping screws provide a robust hold, making them suitable for structural applications where strength is paramount.

Installation Tips

To ensure a secure fit when using self-tapping screws with aluminum

- Choose the Right Screw Size The diameter and length should match the thickness of the aluminum. Overly long screws may penetrate too deep and compromise structural integrity, while screws that are too short may not hold securely.

- Use the Correct Drill Speed If using a power tool, maintain a moderate speed to avoid overheating the screw and damaging the aluminum.

- Prepare the Surface Ensure the aluminum surface is clean and free from debris to promote a better seal and prevent corrosion.

Conclusion

Self-tapping metal screws are essential for applications requiring aluminum fastening. Their ability to self-drill, combined with the strength they provide, makes them ideal for numerous applications in construction and manufacturing. By understanding the types of screws available and following best practices for installation, you can ensure a reliable and lasting connection in your projects. Embrace the efficiency and reliability of self-tapping screws for your next aluminum project, and experience the benefits firsthand.

Latest news

-

Similarities and Differences Between Plain Washer and Spring Washer - Fastener Comparison Guide

NewsJun.10,2025

-

Effortless Installation Self-Drilling Window Screws - Fast, Secure, and Durable Fasteners

NewsJun.10,2025

-

Self Drilling Stucco Screws for Fast, Secure Installation Self Tapping & Self-Tapping Fasteners

NewsJun.10,2025

-

Premium Hot Dipped Galvanized Self Tapping Screws - Durable Corrosion Resistance

NewsJun.09,2025

-

Discover M12 Weld Stud Benefits & Applications Guide

NewsJun.09,2025

-

M25 Stainless Steel Washers High-Durability Fasteners for Corrosion Resistance

NewsJun.09,2025