plain flat washer

دسمبر . 07, 2024 16:08 Back to list

plain flat washer

Understanding Plain Flat Washers An Essential Component in Engineering and Manufacturing

In the world of engineering and manufacturing, even the smallest components play a critical role in ensuring the integrity and safety of assemblies. Among these components, plain flat washers are widely utilized and often overlooked. While they may seem simple and mundane, plain flat washers serve essential functions that are fundamental to the durability and performance of various applications.

What is a Plain Flat Washer?

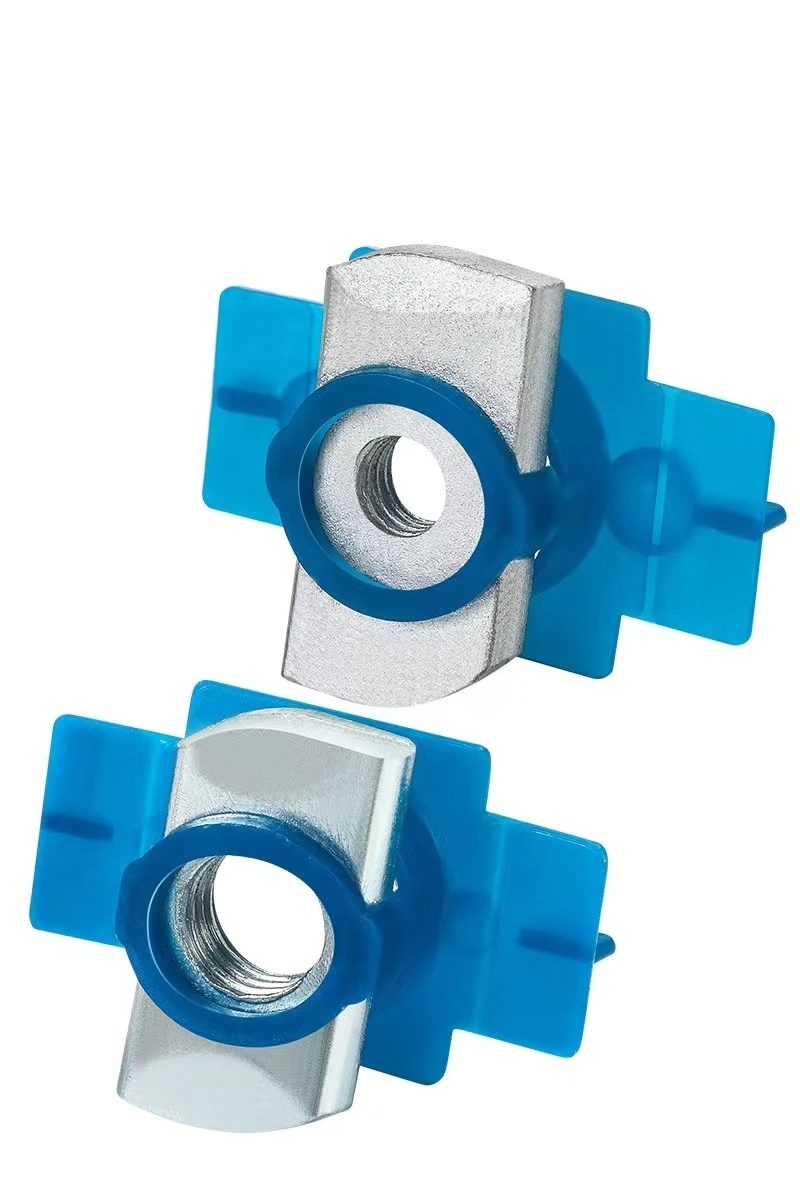

A plain flat washer is a circular disc, typically made of metal, rubber, or plastic, with a hole in the center. These washers are designed to distribute the load of a threaded fastener (such as a bolt or screw) over a larger surface area, reducing the stress on the connecting material and preventing damage. Depending on their purpose and application, plain flat washers come in different sizes and thicknesses to accommodate various types of fasteners and materials.

Functions of Plain Flat Washers

One of the primary functions of plain flat washers is load distribution. When a bolt or screw is tightened, it exerts pressure on the material it is fastened to. Without a washer, this pressure can create localized stress, leading to deformation or even failure of the material. By using a flat washer, the forces exerted by the fastener are spread more evenly, minimizing potential damage.

In addition to load distribution, plain flat washers serve as spacers. In many applications, especially in machinery and structural assemblies, washers can help maintain the correct alignment between components. This ensures that parts fit together as intended and function properly.

plain flat washer

Washers also provide a surface that helps prevent corrosion between dissimilar materials. When two different metals are in contact, there is a risk of galvanic corrosion, which can lead to premature failure. By placing a washer between these materials, the risk of corrosion is significantly reduced, enhancing the longevity of the assembly.

Materials Used for Plain Flat Washers

Plain flat washers are available in various materials, each suited for specific applications. For example, metal washers, typically made from stainless steel, carbon steel, or aluminum, are commonly used in demanding environments due to their strength and durability. Stainless steel washers are particularly prized for their resistance to corrosion, making them ideal for outdoor applications.

Plastic washers are also prevalent, especially in electrical applications where non-conductivity is crucial. Rubber washers, meanwhile, are often used in plumbing applications to create seals that prevent leaks, thanks to their compressibility and elasticity.

Conclusion

While plain flat washers may appear to be simple components, their importance in engineering and manufacturing cannot be overstated. They provide critical functions such as load distribution, spacing, and protection against corrosion and damage. Understanding the role of these washers can enhance the design and durability of assemblies across various industries, from construction and automotive to electronics and plumbing.

When selecting a plain flat washer, it's essential to consider the application, material compatibility, and load requirements to ensure optimal performance. Manufacturers and engineers must recognize the significance of these small but mighty components in achieving reliable, safe, and efficient designs. As we continue to advance in technology and manufacturing processes, the humble flat washer remains an unsung hero in the world of engineering, quietly holding it all together.

Latest news

-

Premium Fasteners Manufacturer | AI-Driven Solutions

NewsAug.01,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | High Strength, Corrosion Resistance

NewsAug.01,2025

-

High-Strength Hot Dip Galvanized Bolts - LongZe | Corrosion Resistance, Custom Sizes

NewsAug.01,2025

-

Best Self Tapping Screws for Drywall - Fast & Secure Installation

NewsJul.31,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&Customization

NewsJul.31,2025

-

Hot Dip Galvanized Bolts-Hebei Longze Metal Products|Corrosion Resistance&High Strength

NewsJul.31,2025