Optimizing Panel Fasteners for Enhanced Structural Integrity and Installation Efficiency

اگست . 19, 2024 20:41 Back to list

Optimizing Panel Fasteners for Enhanced Structural Integrity and Installation Efficiency

The Importance of Panel Fasteners in Modern Construction

In the rapidly evolving field of construction, the integrity and efficiency of building materials are paramount. One crucial component that often goes overlooked is panel fasteners. These small but essential elements play a significant role in ensuring the structural stability and longevity of various construction projects. In this article, we will explore the significance of panel fasteners, their types, applications, and the factors to consider when choosing the right fasteners for a project.

What Are Panel Fasteners?

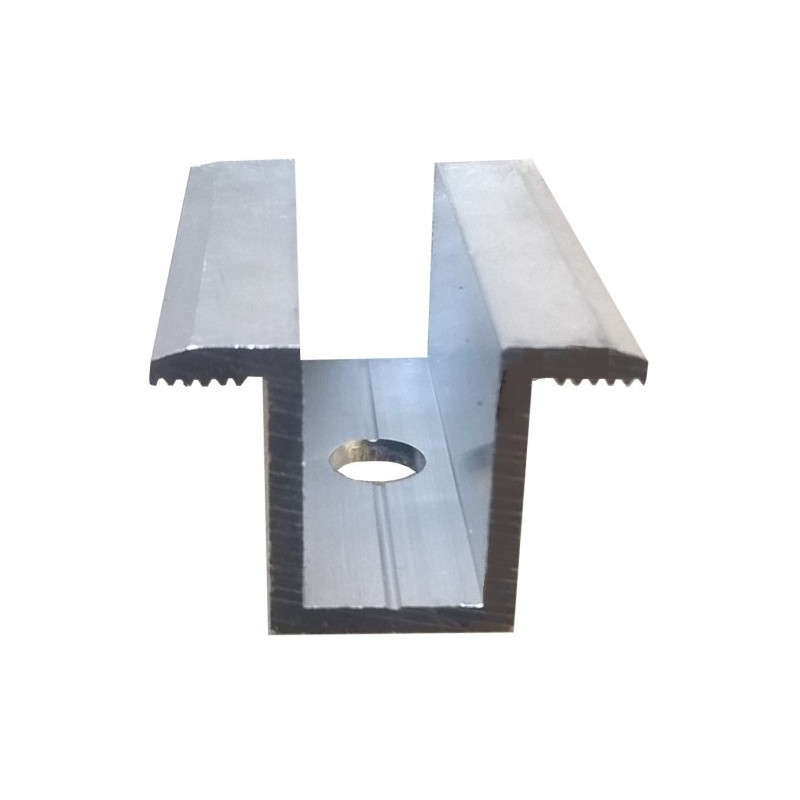

Panel fasteners are specialized hardware used to secure panels, whether they are made of metal, wood, or composite materials, to various structures, including walls, roofs, and floors. Their primary purpose is to create a sturdy connection between components, which is essential for maintaining the overall integrity of the structure. Panel fasteners are available in various forms, including screws, bolts, clips, and rivets, each serving different purposes and applications.

Types of Panel Fasteners

1. Screws Often used for wood and metal panels, screws provide a reliable and strong holding force. They can be self-tapping or require pre-drilled holes, depending on the materials involved.

2. Bolts Commonly used in heavy construction, bolts can handle high loads and are often paired with nuts and washers for added security. They are ideal for assembling large panels in structural frameworks.

3. Clips These fasteners provide a quick and easy solution for attaching panels without the need for drilling. They are widely used in the installation of siding, roofing, and decorative panels, allowing for flexibility and ease of replacement.

4. Rivets Rivets are permanent fasteners used in applications where strong, vibration-resistant connections are required. Commonly seen in aircraft and metal structures, rivets are often preferred for their durability.

Applications of Panel Fasteners

panel fasteners

Panel fasteners are integral to a multitude of applications across various industries. In the construction sector, they are employed in both residential and commercial buildings for siding, roofing, and interior wall paneling. In the automotive industry, panel fasteners secure components of vehicles, from body panels to interiors. Moreover, in the manufacturing sector, these fasteners are used to assemble equipment and machinery, ensuring that parts stay securely attached during operation.

Factors to Consider When Choosing Panel Fasteners

When selecting the right panel fasteners for a project, several factors should be taken into account

1. Material Compatibility It's crucial to choose fasteners that are compatible with the materials being joined. Using dissimilar metals without proper protection can lead to galvanic corrosion, compromising the integrity of the assembly.

2. Load Requirements Assess the load that the fasteners must bear. Heavy-duty applications may require bolts and nuts, while lighter applications could use screws or clips.

3. Environmental Conditions The environment in which the fasteners will be used plays a vital role. Fasteners exposed to moisture or corrosive substances should be made from weather-resistant materials, such as stainless steel or coated finishes.

4. Installation Method Consider how the fasteners will be installed. Some may require specialized tools, while others can be installed quickly and easily by hand.

Conclusion

In conclusion, panel fasteners are essential components in the construction and manufacturing industries that contribute significantly to the stability and durability of various structures. By understanding the different types of fasteners, their applications, and the key factors to consider when selecting them, professionals in the field can ensure the safety and longevity of their projects. Investing time in choosing the right panel fasteners can lead to enhanced performance and reduced maintenance costs, ultimately benefiting the entire construction process.

Latest news

-

Premium Fasteners Manufacturer | AI-Driven Solutions

NewsAug.01,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | High Strength, Corrosion Resistance

NewsAug.01,2025

-

High-Strength Hot Dip Galvanized Bolts - LongZe | Corrosion Resistance, Custom Sizes

NewsAug.01,2025

-

Best Self Tapping Screws for Drywall - Fast & Secure Installation

NewsJul.31,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&Customization

NewsJul.31,2025

-

Hot Dip Galvanized Bolts-Hebei Longze Metal Products|Corrosion Resistance&High Strength

NewsJul.31,2025