Hot Dip Galvanized Bolts - LongZe | High-Strength Corrosion Resistance

جولائی . 29, 2025 20:00 Back to list

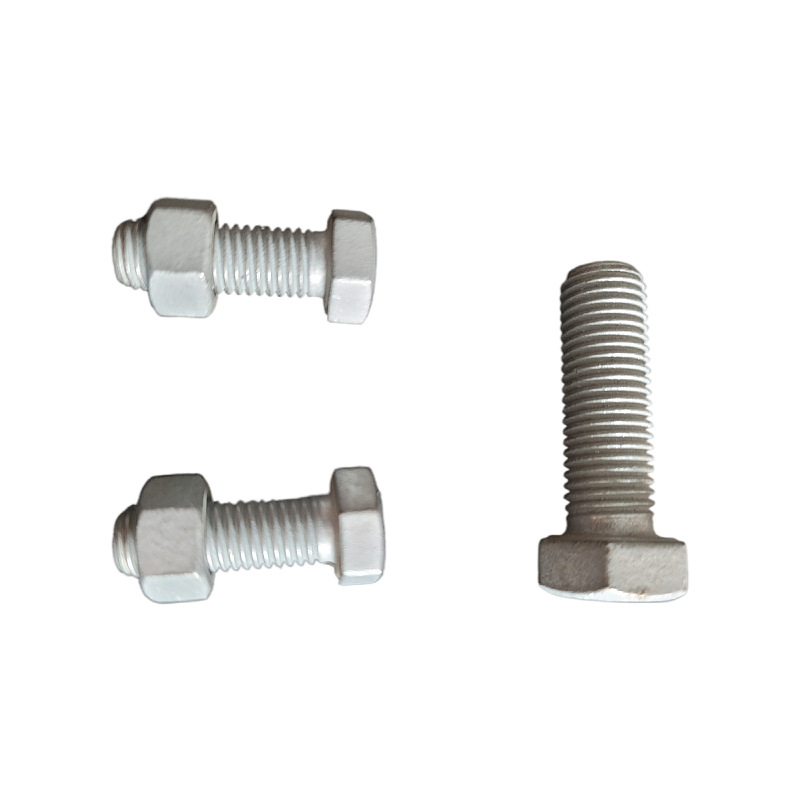

Hot Dip Galvanized Bolts - LongZe | High-Strength Corrosion Resistance

Hot-dip galvanized bolts are essential fasteners in modern industrial and construction applications, offering exceptional strength, corrosion resistance, and durability. This article provides an in-depth analysis of the hot dip galvanized bolts manufactured by Hebei Longze Metal Products Manufacturing Co., Ltd. (LongZe), covering their technical specifications, advantages, and real-world applications.

Product Overview

Produced by LongZe, a leading manufacturer of high-quality fasteners, the hot-dip galvanized bolts are designed to meet rigorous industrial standards. These bolts combine the mechanical strength of Grade 8.8 carbon steel with the protective benefits of hot-dip galvanization, making them ideal for demanding environments.

Key Features and Technical Specifications

Material and Grade

The bolts are available in multiple grades, including 4.8, 5.8, 6.8, 8.8, and 10.9, with Grade 8.8 being the most common for high-strength applications. The materials used include carbon steel (Q235, 35K, 45K, 40Cr, 20MnTiB) and stainless steel variants, ensuring versatility across industries.

Surface Treatments

Options for surface finishes include hot-dip galvanizing, black oxide, zinc plating, and DACROMET, providing tailored corrosion resistance for different environments. The hot dip galvanized bolts are particularly favored for outdoor and marine applications due to their extended lifespan.

Size and Length Variability

The bolts are available in a wide range of sizes, from M6 to M60 (1/4" to 2.5") and lengths from 40mm to 6000mm. Customizable dimensions ensure compatibility with diverse structural and mechanical requirements.

Compliance with International Standards

Manufactured to meet global standards such as ISO, DIN, ANSI, ASME, ASTM, and BS, these bolts adhere to specifications like DIN933 and ISO 4017, ensuring interoperability and quality assurance across international markets.

| Parameter | Details |

|---|---|

| Material | Carbon steel (Q235, 35K, 45K, 40Cr, 20MnTiB), Stainless steel |

| Grade | 4.8, 5.8, 6.8, 8.8, 10.9 |

| Surface Treatment | Hot-dip galvanizing, Black oxide, Zinc plating, DACROMET |

| Size Range | M6-M60 (1/4"-2.5") |

| Length Range | 40mm-6000mm (Customizable) |

| Standards | ISO, DIN, ANSI, ASME, ASTM, BS, JIS |

Advantages of Hot-Dip Galvanized Bolts

Corrosion Resistance

The hot-dip galvanization process coats the bolts with a zinc layer, creating a barrier against moisture and chemicals. This makes them suitable for galvanized anchor bolts in concrete structures and hot dipped galvanized carriage bolts in agricultural machinery.

Strength and Durability

Grade 8.8 and 10.9 bolts offer high tensile strength, making them ideal for heavy hex bolts in infrastructure projects. Their durability reduces the need for frequent replacements, lowering long-term costs.

Adaptability

With customizable dimensions and finishes, these bolts can be tailored for specific applications, such as hot dipped galvanized screws in electrical enclosures or galvanized bolts in industrial equipment.

Applications in Key Industries

Construction and Infrastructure

Used in anchor bolts for concrete to secure structural components, these bolts provide reliable load-bearing capacity. Their corrosion resistance is critical in bridges, towers, and coastal facilities.

Manufacturing and Machinery

High-strength hex bolts are employed in heavy machinery, automotive assembly, and HVAC systems. The full thread design ensures secure fastening in tight spaces.

Marine and Outdoor Environments

The hot dip galvanized bolts are preferred in marine applications, such as shipbuilding and offshore platforms, where exposure to saltwater demands robust corrosion protection.

Company Background: Hebei Longze Metal Products Manufacturing Co., Ltd.

Founded with a focus on innovation and quality, LongZe has established itself as a trusted supplier of fasteners. The company adheres to international standards and invests in advanced manufacturing technologies to ensure precision and reliability. Their commitment to types of bolts and types of screws and bolts reflects their dedication to meeting global market demands.

Industry Standards and Compliance

While the search for specific NIST standards related to hot-dip galvanized bolts encountered technical issues, the U.S. National Institute of Standards and Technology (NIST) plays a critical role in establishing measurement standards for materials and processes. For instance, NIST's research on corrosion resistance and material durability informs industry practices, ensuring that products like these bolts meet rigorous performance criteria.

Conclusion

Hot-dip galvanized bolts from LongZe represent a blend of strength, durability, and corrosion resistance, making them indispensable across industries. Their compliance with international standards, combined with customizable options, ensures they address a wide range of applications. For manufacturers and engineers seeking reliable fasteners, these bolts offer a dependable solution backed by the company's expertise and commitment to quality.

References

NIST (National Institute of Standards and Technology). https://www.nist.gov/

Latest news

-

Hot Dip Galvanized Bolts-About LongZe|High Strength, Corrosion Resistance

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Customization

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

High-Strength Hot-Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, High Strength

NewsJul.30,2025