Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance & Customization

اگست . 11, 2025 23:20 Back to list

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance & Customization

Hot dip galvanized bolts are essential components in modern construction, manufacturing, and engineering. These fasteners combine the strength of high-grade steel with the corrosion resistance of a zinc coating, making them ideal for both industrial and commercial applications. This article explores the features, advantages, technical specifications, and applications of hot dip galvanized bolts, along with insights into the manufacturer, Hebei Longze Metal Products Manufacturing Co., Ltd., and the importance of standards in the industry.

What Are Hot Dip Galvanized Bolts?

Hot dip galvanized bolts are high-strength fasteners coated with a layer of zinc through a hot-dip galvanization process. This method involves immersing the bolts in molten zinc, creating a durable, corrosion-resistant coating that extends their lifespan, especially in harsh environments. These bolts are available in various grades, sizes, and materials, making them suitable for a wide range of applications.

Key features of hot dip galvanized bolts include:

- High Strength: Available in grades such as 4.8, 5.8, 6.8, 8.8, and 10.9, ensuring they meet the demands of heavy-duty applications.

- Corrosion Resistance: The zinc coating protects against rust and degradation, even in outdoor or marine environments.

- Customizable Options: Sizes and lengths can be tailored to specific project requirements.

- Compliance with Standards: Adherence to ISO, DIN, ANSI, ASME, ASTM, and other international standards ensures quality and reliability.

Why Choose Hot Dip Galvanized Bolts?

Hot dip galvanized bolts offer several advantages over other types of fasteners:

1. Superior Corrosion Resistance

The hot-dip galvanization process creates a thick, durable zinc coating that acts as a barrier against moisture and chemicals. This makes these bolts ideal for outdoor structures, bridges, and marine applications. According to the National Institute of Standards and Technology (NIST), zinc coatings are critical for extending the service life of steel components in corrosive environments. (NIST)

2. Enhanced Strength and Durability

Available in high-grade steel such as carbon steel (Grade 8.8) and stainless steel, these bolts are engineered to withstand extreme mechanical stress. Their high tensile strength ensures they remain secure under heavy loads, making them a preferred choice for construction and industrial equipment.

3. Versatility in Applications

Hot dip galvanized bolts are used in diverse industries, including:

- Construction: For structural frameworks, scaffolding, and roofing.

- Manufacturing: In machinery, equipment assembly, and automotive parts.

- Infrastructure: For bridges, highways, and utility poles.

- Marine and Offshore: In shipbuilding, offshore platforms, and coastal structures.

4. Cost-Effective Solution

While hot dip galvanized bolts may have a higher initial cost compared to other fasteners, their long-term durability and low maintenance requirements make them a cost-effective choice. The zinc coating reduces the need for frequent replacements, saving time and resources over the lifespan of the product.

Technical Specifications of Hot Dip Galvanized Bolts

The technical specifications of hot dip galvanized bolts are crucial for ensuring compatibility and performance in different applications. Below is a detailed specification table:

| Parameter | Details |

|---|---|

| Material | Carbon steel (Q235, 35K, 45K, 40Cr, 20MnTiB), Stainless steel (A2, A4) |

| Grade | 4.8, 5.8, 6.8, 8.8, 10.9 |

| Surface Finish | Hot dip galvanized, Zinc plated, Black oxide, Teflon, Dacromet |

| Standards | ISO, DIN, ANSI, ASME, ASTM, BS, AS, JIS, DIN933, DIN931, ISO 4017, EN 24017 |

| Size Range | M6–M60 (1/4”–2.5”), customizable |

| Length Range | 40mm–6000mm (1.57”–236.22”), customizable |

| Types | Hex bolts, Heavy hex bolts, Full thread bolts, Washer bolts |

Applications of Hot Dip Galvanized Bolts

Hot dip galvanized bolts are used in critical applications where strength, durability, and corrosion resistance are paramount. Some common applications include:

1. Structural Engineering

These bolts are widely used in building frameworks, steel structures, and bridges. Their high tensile strength ensures structural integrity, while the zinc coating protects against weathering and rust.

2. Industrial Machinery

In manufacturing plants and industrial equipment, hot dip galvanized bolts are used to secure heavy machinery and components. Their resistance to wear and tear makes them ideal for high-stress environments.

3. Automotive Industry

The automotive sector relies on hot dip galvanized bolts for engine assembly, chassis construction, and body panels. The corrosion resistance ensures long-term reliability even in harsh conditions.

4. Marine and Coastal Projects

For shipbuilding, offshore platforms, and coastal infrastructure, hot dip galvanized bolts are essential. The zinc coating provides protection against saltwater corrosion, ensuring longevity in marine environments.

About Hebei Longze Metal Products Manufacturing Co., Ltd.

Hebei Longze Metal Products Manufacturing Co., Ltd. is a leading manufacturer and supplier of high-quality fasteners, including hot dip galvanized bolts. With decades of experience in the industry, the company is committed to delivering durable, reliable, and cost-effective solutions for global markets.

Key aspects of the company include:

- Advanced Manufacturing Facilities: Equipped with state-of-the-art machinery, the company ensures precision and consistency in production.

- Comprehensive Quality Control: Rigorous testing and inspection processes guarantee compliance with international standards.

- Customization Services: The company offers tailored solutions to meet specific project requirements.

- Global Reach: With a strong export network, Hebei Longze serves clients in North America, Europe, Asia, and beyond.

For more information about Hebei Longze Metal Products Manufacturing Co., Ltd., visit their official website at https://www.lzfasteners.com.

The Importance of Standards in Fastener Manufacturing

Standards play a critical role in ensuring the quality, safety, and interoperability of fasteners. Hot dip galvanized bolts must meet international standards such as ISO, DIN, and ASTM to guarantee performance and reliability. These standards define dimensions, mechanical properties, and testing procedures, ensuring that fasteners are compatible with global systems.

The National Institute of Standards and Technology (NIST) emphasizes the importance of standardization in manufacturing and engineering. As stated on the NIST website, "Standardization ensures that products and services are safe, reliable, and interoperable across industries." (NIST)

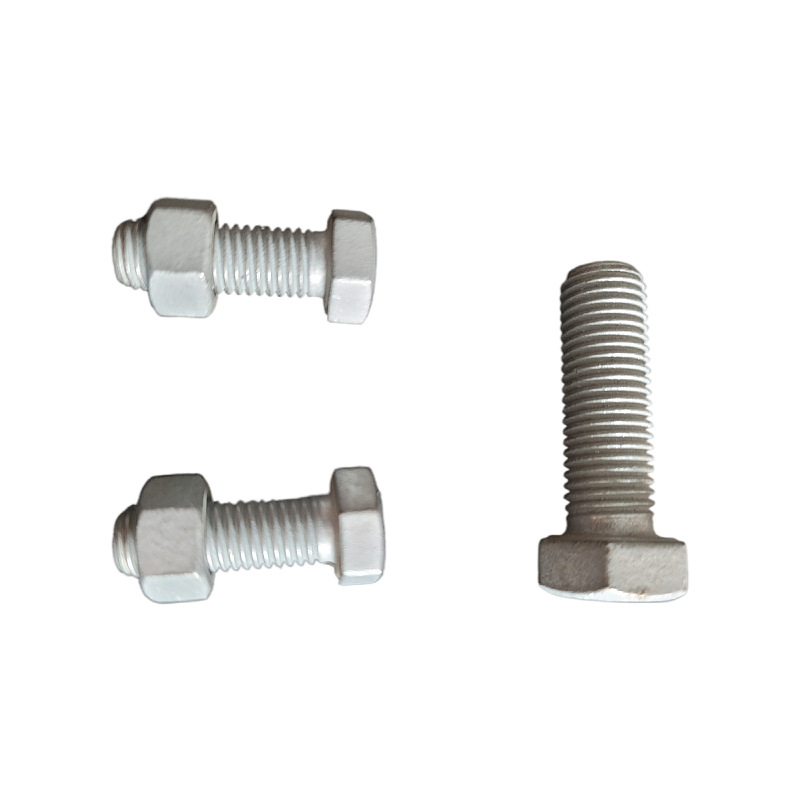

Product Images

Below are the product images of hot dip galvanized bolts:

Conclusion

Hot dip galvanized bolts are a versatile and reliable solution for industrial, construction, and marine applications. Their combination of high strength, corrosion resistance, and compliance with international standards makes them an essential component in modern engineering. Hebei Longze Metal Products Manufacturing Co., Ltd. continues to lead in innovation and quality, providing global clients with high-performance fasteners tailored to their needs.

For more information about hot dip galvanized bolts, visit the product page at https://www.lzfasteners.com/hot-dip-galvanized-bolts.html.

References

National Institute of Standards and Technology (NIST)

Note: The information provided in this article is based on the product specifications and company details from the context. For technical data, compliance standards, or further inquiries, please refer to the official website of Hebei Longze Metal Products Manufacturing Co., Ltd.

Latest news

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Grade 8.8

NewsAug.14,2025

-

Hot Dip Galvanized Bolts: High-Strength Corrosion-Resistant Fasteners | Hebei Longze

NewsAug.14,2025

-

High-Strength Hot Dip Galvanized Bolts - LongZe Metal Products|Corrosion Resistance&Customizable

NewsAug.14,2025

-

10 Different Types of Fasteners: Auto & Anchor Guide

NewsAug.14,2025

-

Hot Dip Galvanized Bolts - Longze | Corrosion Resistance, High Strength

NewsAug.13,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance, Industrial Use

NewsAug.13,2025