Understanding the Functionality and Applications of Double Stud Bolts in Engineering

Ara . 13, 2024 23:17 Back to list

Understanding the Functionality and Applications of Double Stud Bolts in Engineering

Understanding Double Stud Bolts An Essential Component in Engineering

Double stud bolts play a crucial role in the field of engineering and construction, serving as vital components in a variety of applications. They are specifically designed to enhance structural integrity, provide stability, and ensure safety in various assemblies. This article will delve into the design, applications, advantages, and considerations related to double stud bolts.

Design and Composition

A double stud bolt typically consists of a cylindrical metal rod, threaded on both ends. These threads allow for the attachment of nuts or other components, ensuring a secure connection in assemblies. The length of the bolt can vary depending on the specific requirements of the application. Common materials used in manufacturing double stud bolts include carbon steel, stainless steel, and alloy materials, each chosen based on environmental factors such as corrosion resistance and strength.

One significant aspect of double stud bolts is their ability to distribute load evenly across the connected surfaces. This characteristic is vital in applications where stress concentrations could lead to failure. Furthermore, the bolts are designed to accommodate various attachment points, making them versatile in handling different assembly configurations.

Applications

Double stud bolts are widely used across numerous industries, including construction, automotive, aerospace, and marine applications. In construction, for instance, they are often utilized in structural steel frames, connecting beams, and columns to ensure the stability of buildings and bridges. Their ability to provide a strong and reliable connection is fundamental in preventing structural failures.

In the automotive sector, double stud bolts are used for securing components such as engines and suspensions

. Given the dynamic loads and vibrations that vehicles experience, these bolts are engineered to withstand rigorous conditions, ensuring components remain firmly in place during operation.The aerospace industry also relies on double stud bolts, where precision and reliability are critical. In aircraft assembly, these bolts connect various sections of the airframe and help sustain the forces experienced during flight. The aerospace industry's stringent regulations ensure that only the highest quality bolts are used, often requiring detailed certifications and testing.

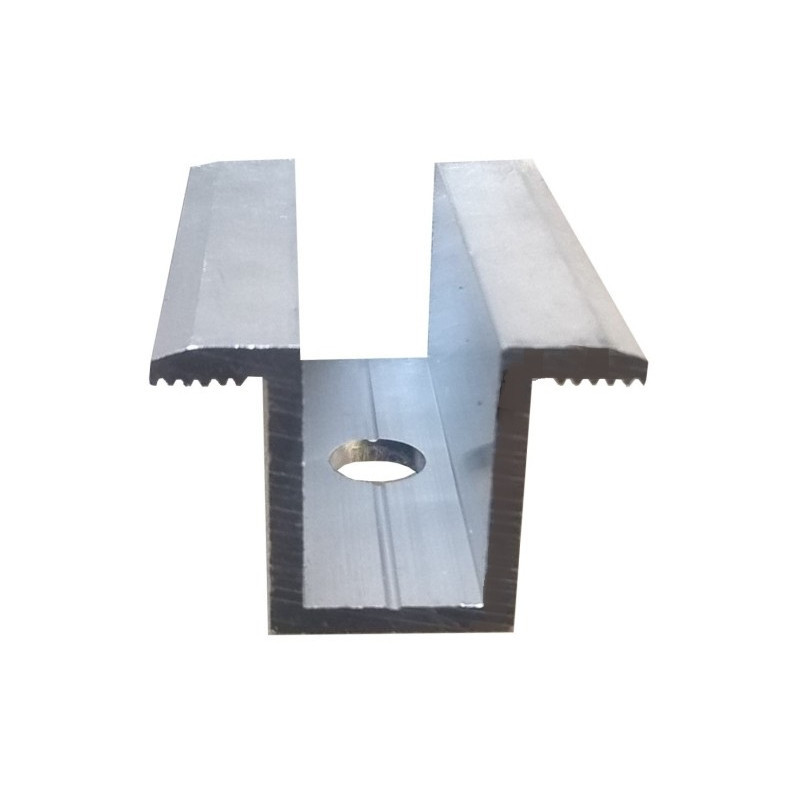

double stud bolt

Advantages

One of the key advantages of double stud bolts is their strength and durability. Unlike conventional bolts, which may rely on a single point of connection, double stud bolts maximize the surface area for load-bearing. This design minimizes the risk of shear failure and enhances overall structural integrity.

Another benefit is ease of installation and maintenance. The dual-threaded features allow for straightforward assembly, and adjusting or replacing components can be accomplished without disassembling an entire assembly. This saves time and reduces labor costs in both construction and maintenance scenarios.

Additionally, double stud bolts can often be reused, which contributes to sustainability in engineering practices. Their robust design means they can withstand multiple cycles of tightening and loosening without losing integrity, making them an economical choice for long-term projects.

Considerations

While double stud bolts offer numerous advantages, certain considerations should be taken into account during their selection and installation. Proper sizing is critical; using bolts that are too small can compromise the connection's strength, while excessively large bolts can lead to unnecessary weight and cost.

Furthermore, it is essential to consider the environmental conditions in which the bolts will be used. Exposure to moisture, chemicals, or extreme temperatures may necessitate the use of specific materials or coatings to prevent corrosion. Regular inspections and maintenance routines should also be established to identify any potential issues before they escalate into serious failures.

Conclusion

In summary, double stud bolts are indispensable components in various engineering applications due to their strength, versatility, and reliability. Their unique design facilitates secure connections in diverse environments, making them a staple in construction, automotive, aerospace, and marine industries. Understanding their applications, advantages, and best practices ensures that they contribute effectively to the structural integrity and longevity of assemblies. As industries continue to evolve, the demand for high-quality fasteners like double stud bolts will remain vital in building a safe and efficient world.

Latest news

-

Hot Dip Galvanized Bolts-About LongZe|High Strength, Corrosion Resistance

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Customization

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

High-Strength Hot-Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, High Strength

NewsJul.30,2025