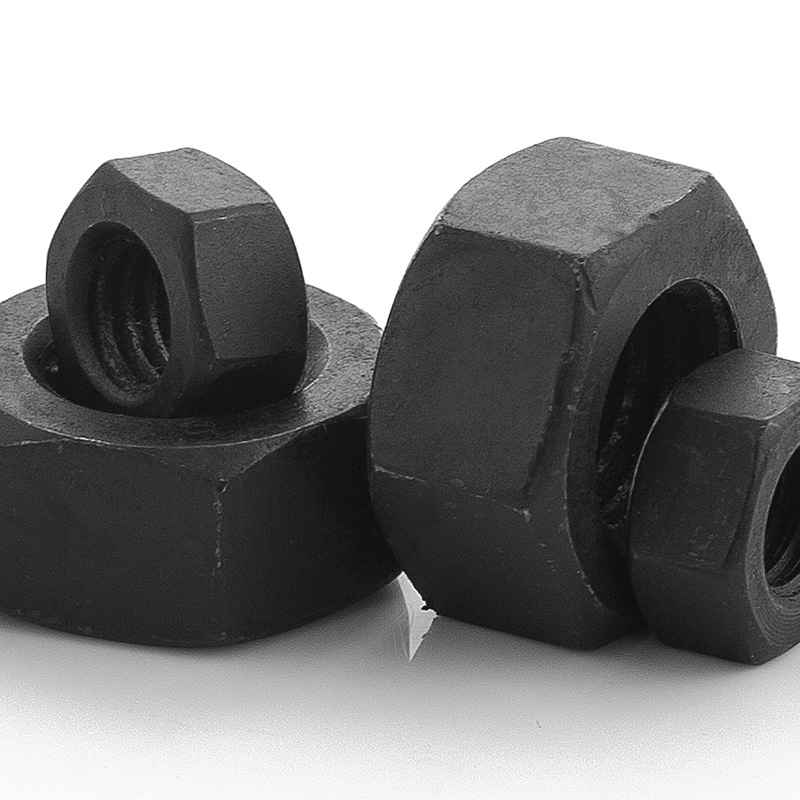

1 4 28 flange nut

ม.ค. . 15, 2025 01:26 Back to list

1 4 28 flange nut

Flange nuts, specifically the 1 4 28 type, play a crucial role in various mechanical and industrial applications. Understanding their unique characteristics, advantages, and potential uses can significantly enhance one's ability to choose the right components for specific projects. As someone who has worked extensively with flange nuts, I bring a wealth of experience and specialized knowledge to help guide your decision-making process.

5. Installation Best Practices Even the highest-quality flange nut can fail if not installed correctly. It's vital to use the right torque to avoid damaging the threads and to ensure that the flange bears evenly against the surface it's fastening. Using a torque wrench is often recommended for precision. Additionally, regular maintenance checks can preempt any loosening, particularly in high-stress environments. 6. Quality Assurance and Supplier Selection Ensuring the quality of your 1 4 28 flange nuts is paramount. Working with reputable suppliers who offer products certified by recognized standards can mitigate the risk of material failure. Look for suppliers who provide detailed specifications and quality assurance processes, which are indicative of their reliability and commitment to excellence. 7. Future Trends and Innovations The landscape for fasteners, including flange nuts, is constantly evolving. Advances in materials science are leading to the development of flange nuts with enhanced properties, such as composite materials that offer both lightweight and superior strength. Understanding these trends can offer competitive advantages in project planning and execution. In conclusion, the 1 4 28 flange nut is a versatile and indispensable component in many industrial applications. By leveraging expertise and applying best practices in material choice, installation, and supplier selection, one can maximize the benefits these small yet mighty fasteners offer. A thoughtful approach ensures not only the success of the current project but also sets a foundation for innovation and excellence in future endeavors.

5. Installation Best Practices Even the highest-quality flange nut can fail if not installed correctly. It's vital to use the right torque to avoid damaging the threads and to ensure that the flange bears evenly against the surface it's fastening. Using a torque wrench is often recommended for precision. Additionally, regular maintenance checks can preempt any loosening, particularly in high-stress environments. 6. Quality Assurance and Supplier Selection Ensuring the quality of your 1 4 28 flange nuts is paramount. Working with reputable suppliers who offer products certified by recognized standards can mitigate the risk of material failure. Look for suppliers who provide detailed specifications and quality assurance processes, which are indicative of their reliability and commitment to excellence. 7. Future Trends and Innovations The landscape for fasteners, including flange nuts, is constantly evolving. Advances in materials science are leading to the development of flange nuts with enhanced properties, such as composite materials that offer both lightweight and superior strength. Understanding these trends can offer competitive advantages in project planning and execution. In conclusion, the 1 4 28 flange nut is a versatile and indispensable component in many industrial applications. By leveraging expertise and applying best practices in material choice, installation, and supplier selection, one can maximize the benefits these small yet mighty fasteners offer. A thoughtful approach ensures not only the success of the current project but also sets a foundation for innovation and excellence in future endeavors.

Next:

Latest news

-

Premium Fasteners Manufacturer | AI-Driven Solutions

NewsAug.01,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | High Strength, Corrosion Resistance

NewsAug.01,2025

-

High-Strength Hot Dip Galvanized Bolts - LongZe | Corrosion Resistance, Custom Sizes

NewsAug.01,2025

-

Best Self Tapping Screws for Drywall - Fast & Secure Installation

NewsJul.31,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&Customization

NewsJul.31,2025

-

Hot Dip Galvanized Bolts-Hebei Longze Metal Products|Corrosion Resistance&High Strength

NewsJul.31,2025