weld stud manufacturers

Out . 11, 2024 06:01 Back to list

weld stud manufacturers

Understanding the Role of Weld Stud Manufacturers in Modern Industries

Weld studs are essential components in various engineering applications, designed to provide strong, permanent attachments between materials. These small yet significant elements are widely used in the automotive, construction, aerospace, and manufacturing industries. Manufacturers of weld studs play a pivotal role in ensuring the quality and reliability of these components. In this article, we will explore the importance of weld stud manufacturers, their production processes, and their impact on different sectors.

The Importance of Weld Studs

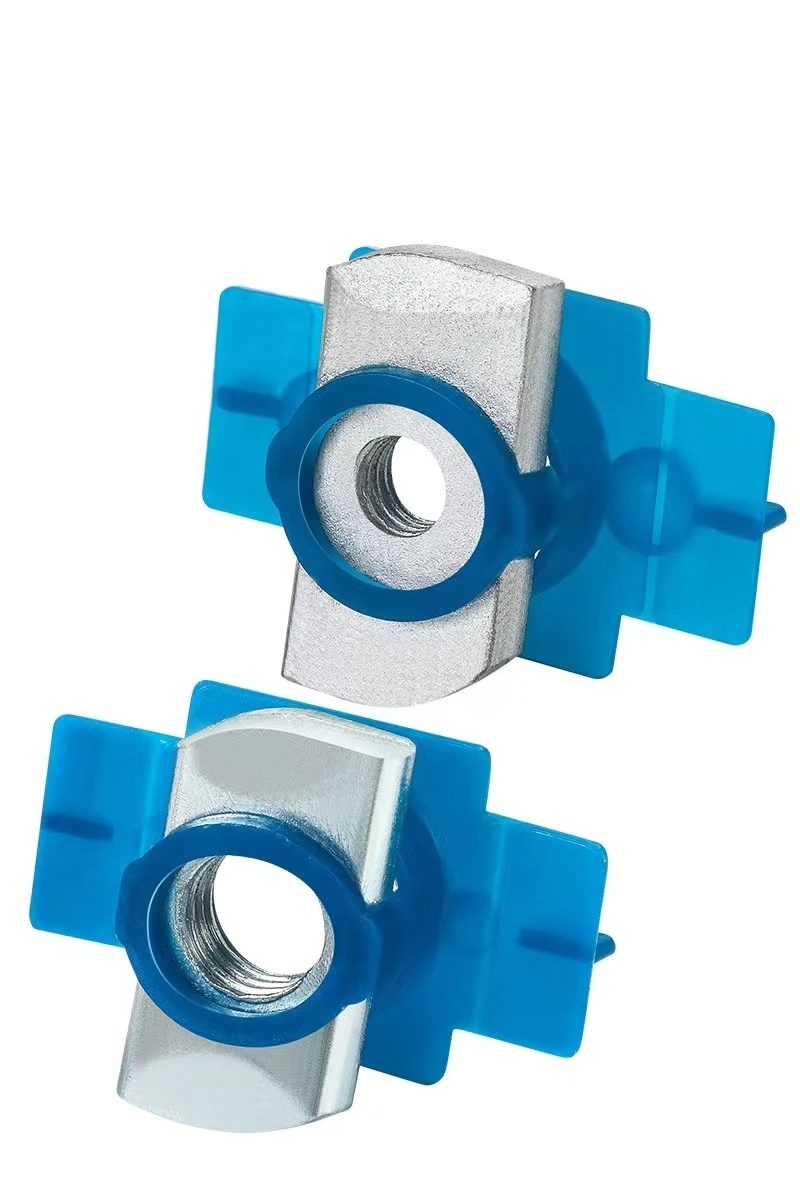

Weld studs are used to join two or more materials, often metals, through a process called stud welding. This method involves the use of an electric arc to melt the end of the stud and the base material, creating a strong bond as they cool and solidify. Weld studs offer several advantages they provide high strength, resist vibration and fatigue, and can be installed quickly and efficiently. Because of these benefits, they have become integral to many applications, from attaching parts in vehicles to securing components in complex machinery.

Role of Weld Stud Manufacturers

Weld stud manufacturers are responsible for producing these critical components with precision and consistency. They must adhere to stringent quality standards to ensure that their products can withstand the demanding conditions in which they will be used. High-quality weld studs are essential for maintaining the integrity and safety of the structures and vehicles they are part of.

These manufacturers utilize advanced technologies and techniques in their production processes. Most weld studs are made from high-strength materials such as stainless steel, carbon steel, or other alloys. The selection of material depends on the specific application and environmental factors, such as corrosion resistance and temperature stability.

Production Processes

The production of weld studs involves several key steps

weld stud manufacturers

2. Forming Manufacturers use various techniques to form the studs, including cold heading and forging. Cold heading involves shaping the material through mechanical deformation, while forging involves applying heat and pressure to create the desired shape.

3. Machining After forming, the studs may require additional machining to achieve precise dimensions and surface finishes.

4. Heat Treatment Depending on the material and intended use, the studs may undergo heat treatment processes to enhance their mechanical properties, such as hardness and tensile strength.

5. Coating and Finishing Finally, weld studs may be coated or finished to improve corrosion resistance and aesthetic appeal. Common coatings include zinc plating and powder coating.

Impact on Industries

The impact of weld stud manufacturers extends across multiple industries. In the automotive sector, weld studs are used to attach body panels, brackets, and various components, contributing to vehicle safety and performance. In construction, they are employed to secure structural elements and enhance the durability of buildings and bridges.

Moreover, with the increasing focus on sustainability and lightweight materials, weld stud manufacturers are constantly innovating. They are exploring new materials and techniques that reduce weight without compromising strength, which is especially important in industries such as aerospace.

Conclusion

Weld stud manufacturers play a crucial role in modern manufacturing and construction. By producing high-quality weld studs that meet industry standards, they ensure the reliability and safety of countless applications. As industries evolve and new technologies emerge, these manufacturers will continue to be at the forefront, developing innovative solutions that meet the changing needs of the market. The importance of their work cannot be understated, as they help build the foundation for a range of products and structures that define our modern world.

Latest news

-

Premium Self Tapping Metal Screws: Strong & Easy Install

NewsAug.02,2025

-

Premium Fasteners Manufacturer | AI-Driven Solutions

NewsAug.01,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | High Strength, Corrosion Resistance

NewsAug.01,2025

-

High-Strength Hot Dip Galvanized Bolts - LongZe | Corrosion Resistance, Custom Sizes

NewsAug.01,2025

-

Best Self Tapping Screws for Drywall - Fast & Secure Installation

NewsJul.31,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&Customization

NewsJul.31,2025