stainless stud bolts

Out . 30, 2024 21:34 Back to list

stainless stud bolts

The Importance and Applications of Stainless Steel Stud Bolts

Stainless steel stud bolts are essential fasteners in various industrial applications, known for their excellent corrosion resistance, high strength, and durability. These specialized bolts are manufactured from stainless steel alloys, primarily composed of iron, chromium, and nickel, which provide exceptional mechanical properties. This article delves into the importance, manufacturing, and applications of stainless steel stud bolts.

Corrosion Resistance

One of the most significant advantages of stainless steel stud bolts is their outstanding resistance to corrosion. Stainless steel's chromium content creates a passive layer of chromium oxide on the surface, which protects the underlying metal from oxidation and corrosion. This makes stainless steel stud bolts ideal for use in harsh environments, such as marine applications, chemical processing plants, and outdoor constructions. They maintain structural integrity and aesthetic appeal even when exposed to moisture, salt, and chemicals.

Strength and Durability

Stainless steel stud bolts are not just resistant to corrosion; they also exhibit remarkable strength. Their high tensile strength allows them to withstand heavy loads and extreme conditions, making them suitable for critical applications in industries like oil and gas, construction, and automotive. The ability to resist deformation and wear means that stainless steel stud bolts can maintain their performance over time, leading to increased reliability and safety in assembled structures.

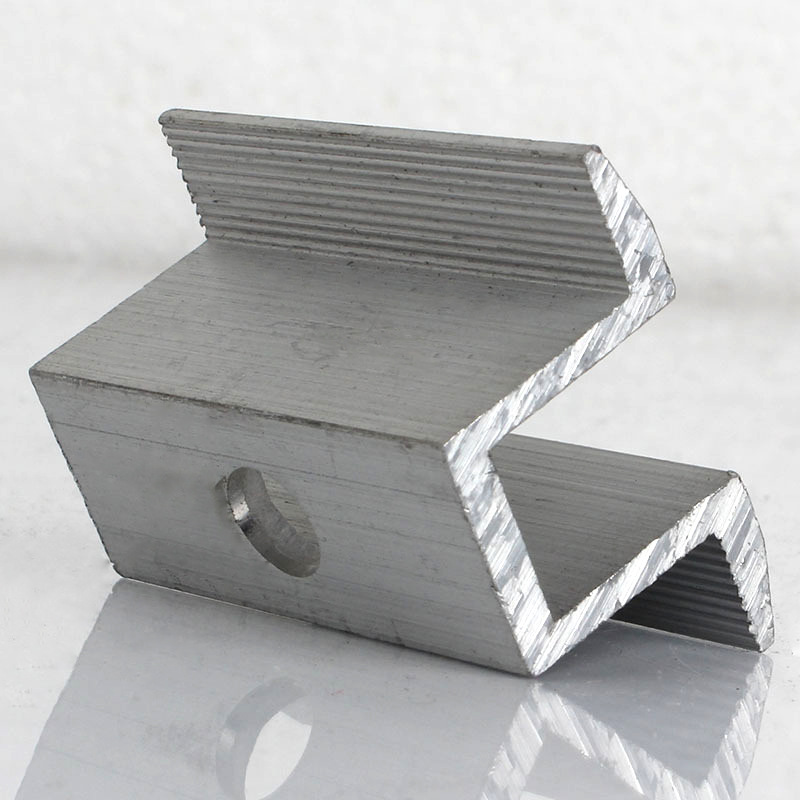

stainless stud bolts

Manufacturing Process

The manufacturing process of stainless steel stud bolts involves several stages, including the selection of raw materials, forging, heat treatment, and surface finishing. High-quality stainless steel is chosen based on the requirements of specific applications, with common grades including 304 and 316. The manufacturing process is carefully controlled to ensure that the final product meets industry standards such as ASTM and ISO. Advanced techniques such as cold working and surface treatments enhance the mechanical properties and corrosion resistance of the bolts further.

Versatile Applications

Stainless steel stud bolts are used across various industries due to their versatility. In the construction industry, they are utilized in structural applications, securing beams, and stabilizing foundations. In the automotive sector, they play a critical role in assembling engines, chassis, and various components that require strong and durable fasteners. The oil and gas industry relies on stainless steel stud bolts for pipelines and pressure vessels, where they withstand extreme pressures and corrosive substances. Additionally, in the food and pharmaceutical industries, where hygiene is paramount, stainless steel’s non-reactive properties make these bolts essential for equipment and machinery.

Conclusion

In summary, stainless steel stud bolts are a vital component of many industrial applications due to their superior corrosion resistance, strength, and versatility. As industries continue to evolve and face new challenges, the demand for reliable fastening solutions will only grow. By understanding the properties and benefits of stainless steel stud bolts, engineers and manufacturers can make informed choices that enhance the performance and longevity of their products and structures. Whether used in marine settings, heavy industry, or manufacturing, stainless steel stud bolts remain an indispensable part of modern engineering solutions.

Latest news

-

Premium Self Tapping Metal Screws: Strong & Easy Install

NewsAug.02,2025

-

Premium Fasteners Manufacturer | AI-Driven Solutions

NewsAug.01,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | High Strength, Corrosion Resistance

NewsAug.01,2025

-

High-Strength Hot Dip Galvanized Bolts - LongZe | Corrosion Resistance, Custom Sizes

NewsAug.01,2025

-

Best Self Tapping Screws for Drywall - Fast & Secure Installation

NewsJul.31,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&Customization

NewsJul.31,2025