Self-Penetrating Screws for Metal Drilling and Tapping Applications in Construction and Manufacturing

Out . 31, 2024 11:20 Back to list

Self-Penetrating Screws for Metal Drilling and Tapping Applications in Construction and Manufacturing

Self-Drilling and Tapping Screws for Metal A Comprehensive Overview

When it comes to fastening materials, the construction and manufacturing industries have increasingly relied on specialized screws designed for the task. Among these, self-drilling and tapping screws have emerged as essential components, especially when working with metal. Understanding their features, applications, and advantages is crucial for selecting the right fastening solution.

What Are Self-Drilling and Tapping Screws?

Self-drilling screws, also known as Tek screws, are equipped with a drill bit-like tip that allows them to penetrate materials without the need for pre-drilling a pilot hole. This feature significantly reduces installation time and simplifies the fastening process. The tapping screw aspect indicates that these screws can create their own threads as they are driven into the material, enhancing grip and ensuring a secure fit.

These screws are made from high-strength materials, often coated to resist corrosion, making them ideal for metal applications. Their design accommodates various thicknesses of metals, from thin sheets to heavier gauges, providing versatility across multiple projects.

Applications

Self-drilling and tapping screws find a wide array of applications in the metalworking industry. They are commonly used in roofing, siding, metal framing, and HVAC installations. In roofing, for instance, these screws are essential for attaching metal sheets, as they ensure watertight seals and durability against harsh weather conditions.

In construction, the screws are invaluable for assembling metal structures, fasteners, and support systems

. They are also prominently featured in manufacturing processes where metal components need to be joined quickly and securely.Advantages

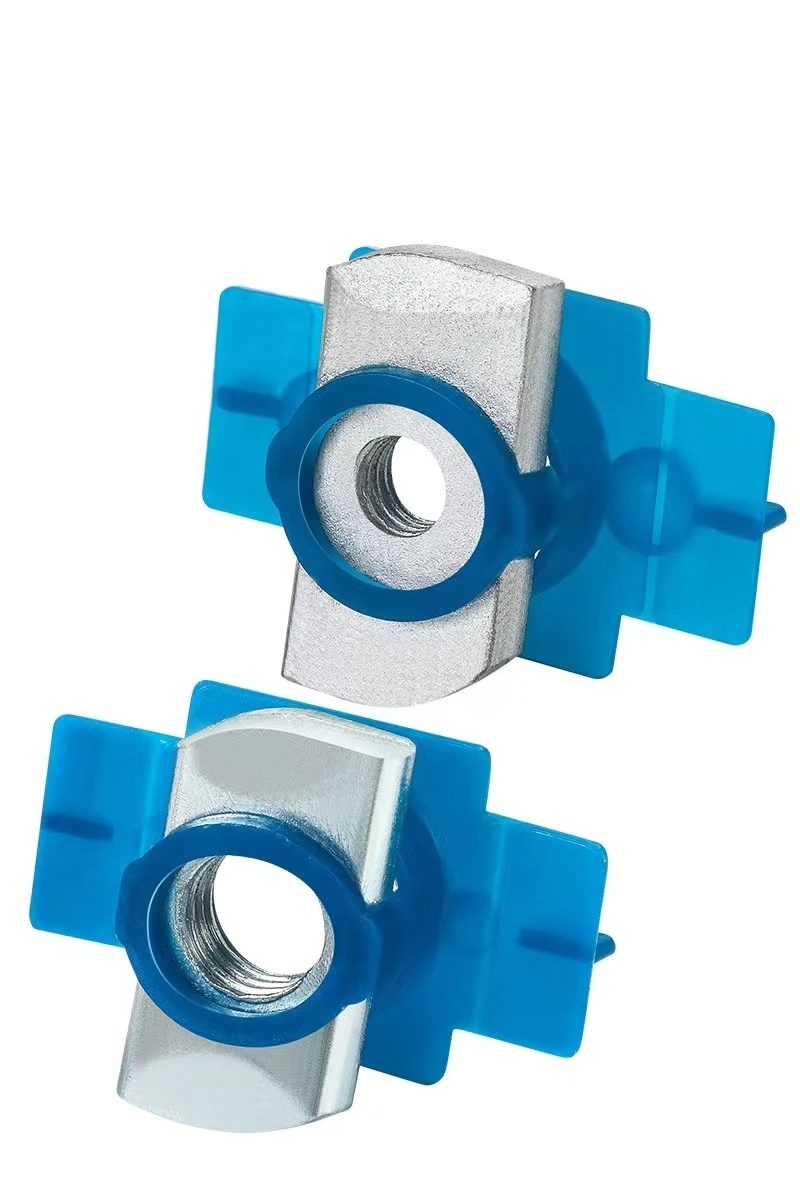

self drilling and tapping screws for metal

The use of self-drilling and tapping screws offers several advantages

1. Time Efficiency The self-drilling capability eliminates the need for pre-drilling, significantly reducing labor time on jobs. This feature is especially beneficial in fast-paced industrial environments where efficiency is crucial.

2. Cost-Effectiveness With the reduced need for additional tools and labor, these screws can lead to cost savings in both materials and overall project expenditures.

3. Strong, Reliable Joints The ability to drill and tap provides strong, consistent threads in metal, ensuring a tight fit that withstands vibration and movement. This characteristic is particularly important in applications like automotive manufacturing and construction, where structural integrity is critical.

4. Versatility Available in various sizes and types, these screws can accommodate numerous applications. Whether working with thin sheets of aluminum or thick steel, contractors can select the appropriate screw that meets their requirements.

5. Corrosion Resistance Many self-drilling screws are treated with coatings that enhance their resistance to rust and environmental degradation, making them suitable for both indoor and outdoor applications.

Conclusion

Self-drilling and tapping screws are indispensable tools in metalworking and construction. Their innovative design provides efficiency, strength, and versatility, catering to the diverse needs of the industry. As projects become more ambitious and demand for durable fastening solutions increases, understanding and utilizing these screws will remain vital for contractors and manufacturers alike. Investing in quality self-drilling and tapping screws can lead to enhanced performance and long-lasting results in any metal application.

Latest news

-

Hot Dip Galvanized Bolts - Lanzhou Fasteners Co., Ltd.|Corrosion Resistance&Industrial Applications

NewsJul.13,2025

-

[Product Name]-[Company Name]|[Key Feature 1]&[Key Feature 2]

NewsJul.13,2025

-

SmartFlow Pro- SmartFlow AI | Enterprise Software Solutions, AI Automation, Workflow Optimization

NewsJul.13,2025

-

Smart Warehouse Solutions-ExampleCompany|Real-Time Inventory Tracking&AI-Powered Analytics

NewsJul.12,2025

-

Advanced Production Solutions-[Company Name]|AI-Driven Predictive Maintenance&Energy Efficiency

NewsJul.12,2025

-

Mild Steel Stud Bolt - High Strength Fastener for Industrial Applications

NewsJul.08,2025