Understanding DIN 127 ISO Standards for Washer Applications in Engineering and Manufacturing Processes

Aug . 14, 2024 14:47 Back to list

Understanding DIN 127 ISO Standards for Washer Applications in Engineering and Manufacturing Processes

Understanding DIN 127 and ISO Standards in Washers

In the world of mechanical engineering and manufacturing, the importance of standards cannot be overstated. Among these standards, DIN 127 and its counterpart in ISO 7089 play crucial roles in the specification and use of flat washers. These standards not only ensure uniformity but also enhance safety, reliability, and performance in various applications.

Overview of DIN 127 and ISO 7089

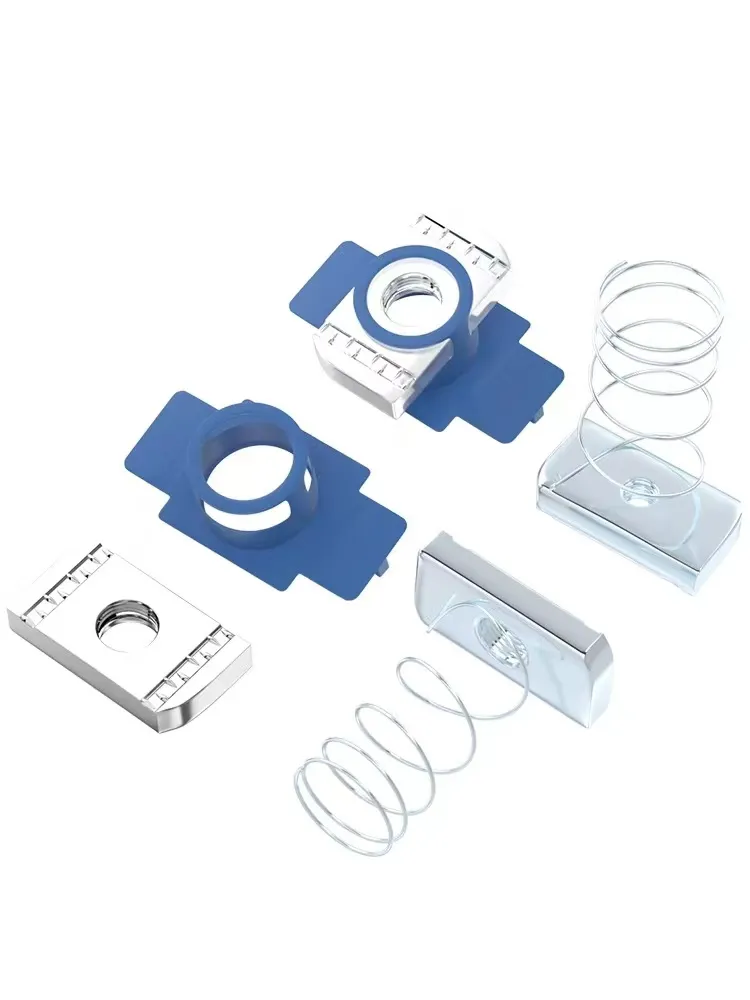

DIN 127 is a German standard that specifies the dimensions and performance criteria for spring washers, particularly those characterized as spring washers for bolts and nuts. Similarly, ISO 7089 is an international standard that covers flat washers used primarily under head bolts and nuts. Both standards provide details regarding dimensions, material specifications, and testing methods, ensuring that washers conform to established mechanical properties.

Flat washers, under ISO 7089, are available in several sizes, each defined by their outer and inner diameters as well as thickness. These washers serve critical functions by distributing loads over a larger area, preventing surface damage, and enhancing the stability of bolted connections.

Importance of Washers

Washers are essential components in mechanical assemblies. Without adequate washers, bolted joints can experience significant problems such as loosening under vibration, surface damage, and fatigue failure. By adhering to standards like DIN 127 and ISO 7089, manufacturers and engineers can ensure that the washers utilized in their designs will perform effectively under the expected loads and stresses.

Spring washers as specified by DIN 127, for instance, feature a curved design that allows for the storage of energy. This energy is then released to maintain tension in a bolted connection, effectively counteracting the forces that cause loosening. Spring washers are particularly advantageous in scenarios with high vibration, making them indispensable in industries such as automotive and aerospace.

din127 iso

Material Considerations

Both DIN and ISO standards emphasize the importance of selecting appropriate materials for washers. Common materials include carbon steel, stainless steel, and various alloys, each chosen based on the required strength, corrosion resistance, and weight considerations. The choice of material directly affects the performance and longevity of the washer, hence compliance with the specified standards is crucial for ensuring quality and durability.

Manufacturing Compliance and Quality Control

Adhering to DIN 127 and ISO 7089 not merely guarantees that the washers will meet universal requirements, but also offers a framework for manufacturers to ensure consistent quality. By implementing rigorous quality control measures, companies can reduce the risk of failures in their products. This, in turn, minimizes liability issues and enhances customer satisfaction.

ISO certification for manufacturers is often a requirement in many industries today. This certification signifies that a company’s products and processes meet international standards, which can improve marketability and consumer trust.

Conclusion

In conclusion, DIN 127 and ISO 7089 are fundamental standards in the realm of mechanical connectors. The importance of these specifications lies not just in their ability to normalize the production of washers, but also in the broader implications for safety, performance, and reliability in engineering applications. As industries continue to evolve with technological advancements, adherence to these standards will remain pivotal. Manufacturers, engineers, and quality control professionals must continually educate themselves on these standards to ensure optimal performance in their assemblies and instill confidence in their products. By recognizing the crucial role of washers and adhering to the established standards, the integrity of mechanical systems can be effectively safeguarded.

Latest news

-

Hot Dip Galvanized Bolts-About LongZe|High Strength, Corrosion Resistance

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Customization

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

High-Strength Hot-Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, High Strength

NewsJul.30,2025