tee bolts

Nov . 19, 2024 21:32 Back to list

tee bolts

Understanding Tee Bolts Applications, Types, and Installation

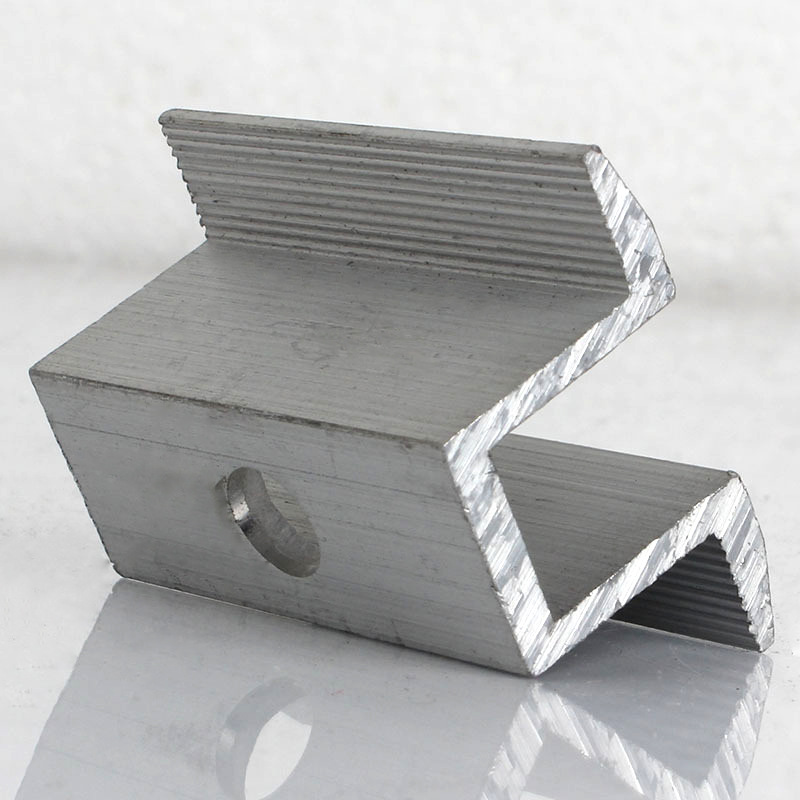

When it comes to fastening solutions in industrial and construction settings, tee bolts are a popular choice due to their unique design and versatility. A tee bolt is essentially a type of fastener that features a head shaped like the letter 'T', allowing it to be inserted into a slot or channel and secured into place. This article will explore the various applications, types, and installation methods of tee bolts, providing you with comprehensive knowledge about this essential fastening component.

Applications of Tee Bolts

Tee bolts are widely used in various industries, including manufacturing, construction, and automotive. Their primary application lies in securing components where a strong and stable fastening solution is required. Some common applications include

1. Machinery Assembly In the manufacturing process, machines often require components to be securely fastened together. Tee bolts provide a reliable means of connecting parts in equipment ranging from heavy machinery to lighter tools.

2. Furniture Construction In the furniture industry, tee bolts are frequently used to assemble pieces such as tables, chairs, and cabinetry. Their ability to provide a strong connection makes them ideal for ensuring furniture stability.

3. Rail and Track Support Tee bolts are also utilized in railways and track installations, where they secure rails to wooden or metal ties, ensuring safety and stability for trains.

4. Construction Frameworks In construction, tee bolts are often employed in the assembly of frameworks for buildings, bridges, and other structures, providing rigidity and strength to critical connections.

Types of Tee Bolts

Tee bolts come in various designs and materials, each suited for specific applications. Understanding the different types can help you choose the right one for your project

1. Material Types Common materials used for tee bolts include stainless steel, carbon steel, and plastic. Stainless steel is ideal for outdoor or corrosive environments, while carbon steel provides strength for indoor applications. Plastic tee bolts are lightweight and non-corrosive, making them suitable for specific furniture applications.

tee bolts

2. Coating Options Tee bolts can be coated with various finishes such as zinc plating, black oxide, or powder coating. These coatings enhance corrosion resistance and can improve aesthetic appeal, especially in visible applications.

3. Head Styles Different head styles may be available, including hex, square, or round designs. The choice of head style often depends on the tools available for installation and the space restrictions within the assembly area.

Installation of Tee Bolts

Installing tee bolts requires a few basic tools and steps. Here’s a simple guide to help facilitate their installation

1. Gather Tools You will typically need a wrench, a socket set, and possibly a ratchet or screwdriver, depending on the head type of the tee bolt.

2. Preparation Ensure the work area is clean and that you have all components ready for assembly. If using in slots, check that the slots are appropriately sized for the tee bolt.

3. Placement Insert the straight end of the tee bolt into the designated slot or hole in the component being fastened. Ensure that the head rests snugly against the surface.

4. Fastening Depending on the design, either screw on a nut or use a wrench to tighten the bolt. Ensure it is adequately fastened for a secure connection, but avoid over-tightening, which could damage the materials involved.

5. Final Checks After installation, double-check that all components are assembled correctly and that the tee bolts are secure.

Conclusion

Tee bolts are an indispensable fastening solution in many industries, blending strength with versatility. Whether you're involved in machinery assembly, furniture construction, or automotive manufacturing, understanding the applications, types, and installation methods for tee bolts can significantly enhance the quality and integrity of your projects. With the right approach and knowledge, you can leverage the benefits of tee bolts for effective and durable assembly solutions.

Latest news

-

Premium Fasteners Manufacturer | AI-Driven Solutions

NewsAug.01,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | High Strength, Corrosion Resistance

NewsAug.01,2025

-

High-Strength Hot Dip Galvanized Bolts - LongZe | Corrosion Resistance, Custom Sizes

NewsAug.01,2025

-

Best Self Tapping Screws for Drywall - Fast & Secure Installation

NewsJul.31,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&Customization

NewsJul.31,2025

-

Hot Dip Galvanized Bolts-Hebei Longze Metal Products|Corrosion Resistance&High Strength

NewsJul.31,2025