stud bolt manufacturers

Oct . 20, 2024 11:03 Back to list

stud bolt manufacturers

Understanding Stud Bolt Manufacturers A Comprehensive Overview

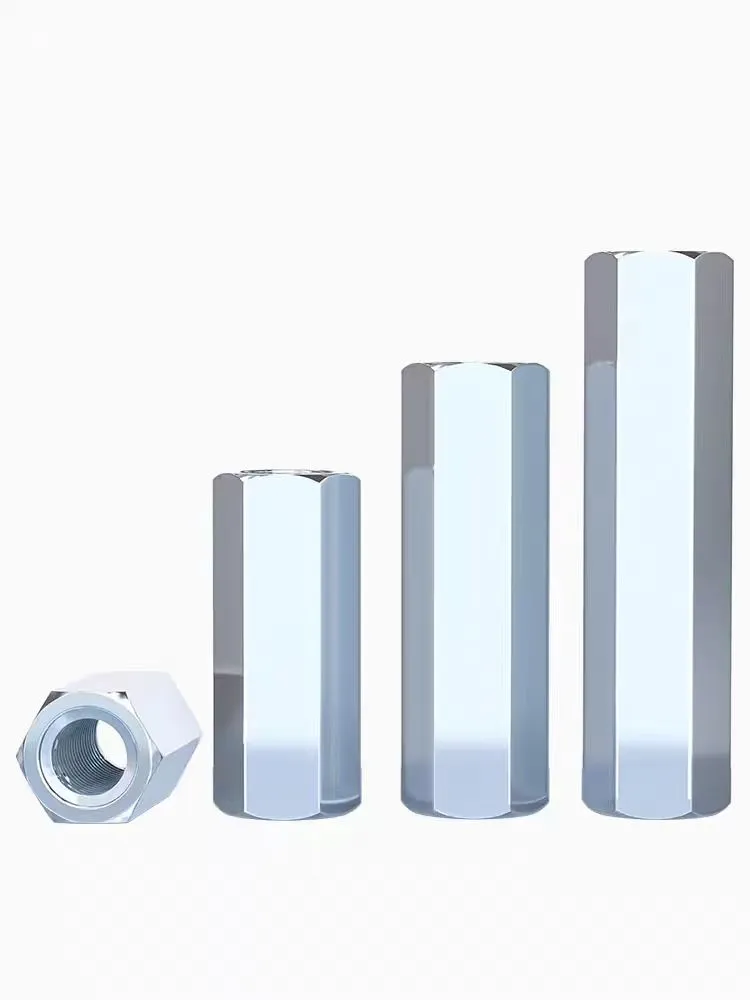

Stud bolts are critical components in various industries, serving as fasteners that connect two or more objects together with precision and stability. These fasteners are particularly essential in environments where heavy loads are encountered, such as in construction, oil and gas, marine, and power generation industries. The demand for stud bolts continues to grow, prompting the emergence of numerous manufacturers capable of producing these vital components. This article delves into the world of stud bolt manufacturing, exploring the types of manufacturers, production processes, quality standards, and factors to consider when selecting a stud bolt manufacturer.

Types of Stud Bolt Manufacturers

Stud bolt manufacturers can be categorized into several types, each specializing in different materials, sizes, and specifications. Some manufacturers focus on standard products, adhering to industry standards such as ASTM, ASME, or ISO. Others may provide custom solutions tailored to specific client needs, offering a wider range of materials, including carbon steel, stainless steel, and high-strength alloys.

Large-scale manufacturers often serve the major industrial sectors by supplying bulk quantities of stud bolts for various applications. Smaller, niche manufacturers may specialize in high-performance fasteners or offer unique coatings designed to enhance corrosion resistance, improving longevity in harsh environments.

Production Processes

The manufacturing of stud bolts generally involves several crucial steps, including material selection, forging, machining, heat treatment, and finishing. First, manufacturers select high-quality raw materials to ensure strength and durability. The typical process begins with forging, where heated metal is shaped into the bolt’s rough form. This is followed by machining, which helps achieve precise dimensions and threading necessary for the fastener’s intended use.

Heat treatment is a critical step that enhances the mechanical properties of the stud bolts, ensuring they can withstand the stresses they will encounter in service. Finally, finishing processes such as plating or coating are applied to improve corrosion resistance and aesthetic appeal.

stud bolt manufacturers

Quality Standards

Given the critical nature of stud bolts in various applications, adherence to quality standards is paramount. Leading manufacturers often comply with international standards, ensuring their products are safe and reliable. The American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO) set standards that many manufacturers strive to meet.

Quality assurance processes, including tensile testing, hardness testing, and dimensional inspections, are integral to maintaining high manufacturing standards. These processes help prevent defects and ensure that each batch of stud bolts is capable of performing under the required load conditions.

Choosing a Stud Bolt Manufacturer

When selecting a stud bolt manufacturer, several factors should be considered. First, evaluate their experience and reputation in the industry. Established manufacturers with a proven track record are often more reliable. Next, assess the manufacturer’s capability to meet specific material and design requirements, especially if custom solutions are needed.

Additionally, consider the manufacturer’s commitment to quality and their adherence to industry standards. Requesting certifications and reviewing customer testimonials can provide insight into their quality assurance practices. Finally, take into account the manufacturer’s lead times and customer service, as these aspects can significantly impact project timelines and efficiency.

Conclusion

Stud bolt manufacturers play a vital role in numerous industries by providing essential fasteners that ensure structural integrity and safety. With various manufacturers available, it’s important for businesses to conduct thorough research and select a manufacturer that meets their specific needs. By focusing on quality, reliability, and experience, companies can ensure they receive the best stud bolts for their applications, contributing to the overall success of their projects.

Latest news

-

Premium Fasteners Manufacturer | AI-Driven Solutions

NewsAug.01,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | High Strength, Corrosion Resistance

NewsAug.01,2025

-

High-Strength Hot Dip Galvanized Bolts - LongZe | Corrosion Resistance, Custom Sizes

NewsAug.01,2025

-

Best Self Tapping Screws for Drywall - Fast & Secure Installation

NewsJul.31,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&Customization

NewsJul.31,2025

-

Hot Dip Galvanized Bolts-Hebei Longze Metal Products|Corrosion Resistance&High Strength

NewsJul.31,2025