stainless steel self tapping hex head screws

Dec . 01, 2024 11:51 Back to list

stainless steel self tapping hex head screws

The Versatility and Strength of Stainless Steel Self-Tapping Hex Head Screws

When it comes to fastening applications in various industries, stainless steel self-tapping hex head screws stand out as a top choice. Their unique design and robust material properties make them an essential component in construction, manufacturing, and repairs. This article explores the features, advantages, and uses of these versatile fasteners.

What Are Stainless Steel Self-Tapping Hex Head Screws?

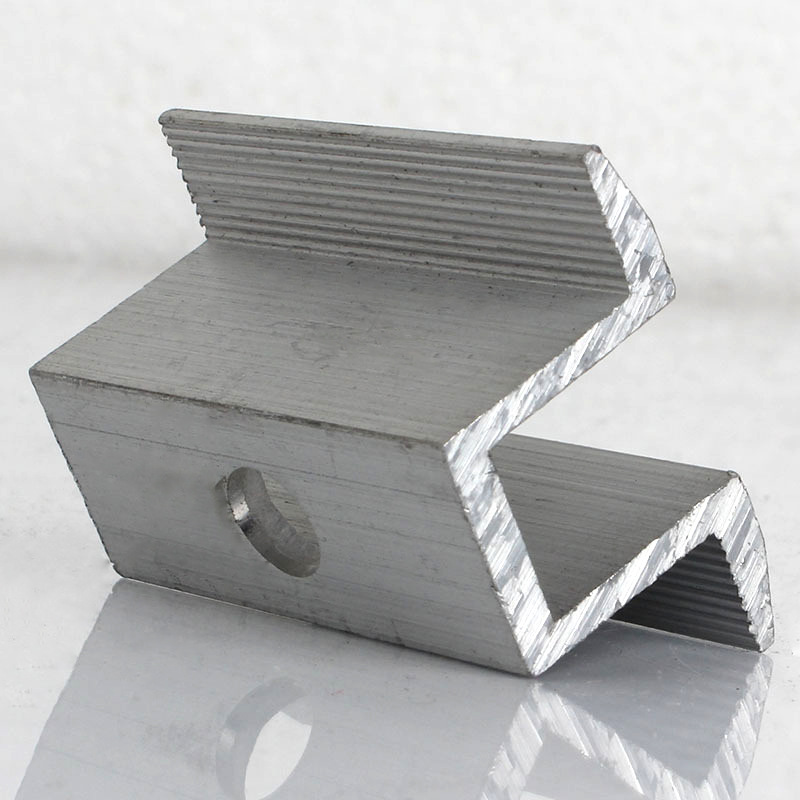

Stainless steel self-tapping hex head screws are specialized fasteners designed to create their own threads in materials they are driven into. Unlike traditional screws that require pre-drilled holes, self-tapping screws can embed themselves into a variety of substrates, including wood, metal, and plastic. Their hexagonal head allows for easy tightening and loosening with a wrench or socket, providing a strong grip and torque.

Material Benefits

The use of stainless steel in these screws offers many benefits. Stainless steel is renowned for its excellent corrosion resistance, strength, and durability. This makes it ideal for applications exposed to moisture, chemicals, or harsh environments. The alloy’s chromium content forms a protective layer on the surface, preventing rust and extending the lifespan of the screw. This characteristic is especially beneficial for outdoor construction, maritime applications, and any setting where the fastener may be subjected to challenging conditions.

Design Features

The hex head design contributes significantly to the functionality of these screws. The larger surface area of a hexagonal head allows for more torque to be applied without stripping the head, making installation easier and more efficient. Furthermore, the self-tapping feature minimizes the need for additional tools, streamlining the fastening process and saving time. The screws are also available in different lengths and diameters, providing versatility to suit various applications.

stainless steel self tapping hex head screws

Applications

Stainless steel self-tapping hex head screws are used across a wide range of industries. In construction, they are commonly employed in metal framing, roofing, and siding applications. Their ability to bond strongly with materials such as steel and aluminum makes them ideal for structural applications. In manufacturing, these screws are essential for assembling machinery, equipment, and fixtures.

They are also favored in the automotive and marine sectors due to their resistance to rust and corrosion. In these environments, where fasteners are often exposed to water and salt, the longevity provided by stainless steel self-tapping screws ensures reliability and safety.

Installation Efficiency

One of the key advantages of using stainless steel self-tapping hex head screws is the efficiency of installation. Since they do not require pilot holes, labor time is significantly reduced. This ease of use leads to faster project completion, making these screws a favorite among contractors and DIY enthusiasts alike. The straightforward installation process does not compromise the strength of the connection, making them a reliable choice for many applications.

Conclusion

In summary, stainless steel self-tapping hex head screws are an essential tool in the arsenal of any builder, contractor, or DIY enthusiast. Their corrosion resistance, combined with ease of installation and robust design, makes them suitable for a multitude of applications across various industries. Whether used in construction, manufacturing, or repairs, these screws provide lasting strength and durability, proving to be a wise investment for any project. As industries continue to evolve, the demand for reliable fasteners like stainless steel self-tapping hex head screws will remain prevalent, ensuring their place as a staple in fastening solutions.

Latest news

-

High-Strength Hot-Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, High Strength

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance, Grade 8.8

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance,High Strength

NewsJul.29,2025

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze Metal Products Manufacturing Co., Ltd.|corrosion resistance&high strength

NewsJul.29,2025