stainless steel reducing washers - a fastener

Nov . 23, 2024 23:42 Back to list

stainless steel reducing washers - a fastener

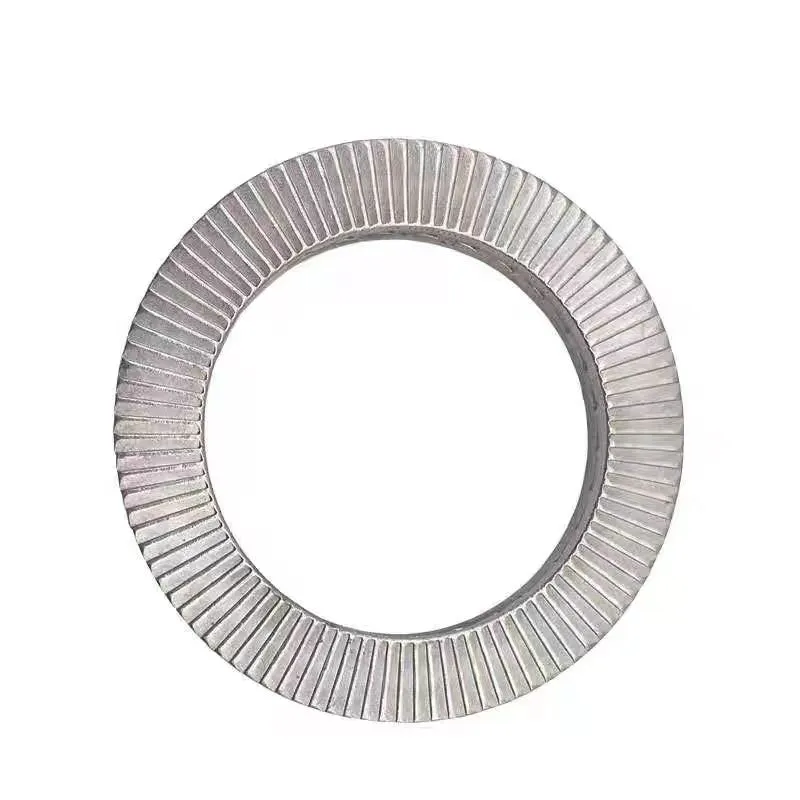

Understanding Stainless Steel Reducing Washers A Fastener Essential

When it comes to fastening applications, the importance of selecting the right components cannot be overstated. Among these components, reducing washers—particularly those crafted from stainless steel—play a pivotal role in ensuring mechanical stability and durability. This article delves into the characteristics, applications, and advantages of stainless steel reducing washers, underscoring their essential function in various industries.

What is a Reducing Washer?

A reducing washer, also known as a stepped washer, is designed with a central hole of varying diameters. This unique feature allows it to adapt to different bolt or screw sizes while maintaining a secure fit. By increasing the surface area contact between the fastener head and the material, reducing washers minimize the risk of damaging the working surface. They are available in multiple sizes, thicknesses, and materials, with stainless steel being one of the most popular choices.

Why Choose Stainless Steel?

Stainless steel is renowned for its resistance to corrosion, high temperatures, and abrasion, making it an ideal material for washers used in challenging environments. This resistance is primarily due to the presence of chromium, which forms a protective layer on the steel surface, preventing rust and degradation. In applications where exposure to moisture, chemicals, or harsh conditions is a concern, stainless steel reducing washers ensure longevity and reliability.

Applications of Stainless Steel Reducing Washers

1. Construction In the construction industry, stainless steel reducing washers are essential for securing beams, columns, and other structural elements. They provide added support and load distribution, preventing material fatigue.

2. Automotive Fasteners in vehicles must withstand vibrations, temperature fluctuations, and potential exposure to corrosive elements. Reducing washers made from stainless steel help secure components in engines and bodywork, enhancing durability and performance.

stainless steel reducing washers - a fastener

4. Manufacturing In manufacturing processes, precision is key. Stainless steel reducing washers support assembly lines by providing a reliable fit for various machinery parts, thus enhancing operational efficiency.

5. Aerospace The aerospace industry often demands materials that can endure extreme conditions. Stainless steel reducing washers provide the necessary strength and resistance to vibrations and thermal expansion, crucial for aircraft components.

Advantages of Using Stainless Steel Reducing Washers

1. Corrosion Resistance The primary benefit of stainless steel is its ability to resist rust and corrosion, which prolongs the life of the fastener and the components it is securing.

2. Strength and Durability Stainless steel is characterized by high tensile strength, meaning reducing washers can handle significant loads without deforming, ensuring a stable connection.

3. Versatility The adjustable nature of reducing washers allows them to accommodate various bolt sizes, making them highly versatile for different applications.

4. Aesthetic Appeal Stainless steel often has an attractive finish, making these washers suitable for applications where appearance matters, such as in visible hardware components.

5. Cost-Effectiveness While stainless steel can be more expensive than other materials, its longevity and reliability can lead to long-term cost savings, particularly in maintenance-heavy environments.

Conclusion

Stainless steel reducing washers are crucial components in a myriad of applications across industries. Their ability to adapt to different bolt sizes while providing strength, durability, and corrosion resistance makes them a favored choice among engineers and manufacturers. As industries continue to evolve and demand higher standards of quality and reliability, the role of stainless steel reducing washers in fastening solutions will undoubtedly remain significant, ensuring that critical components function efficiently and effectively.

Latest news

-

Hot Dip Galvanized Bolts-About LongZe|High Strength, Corrosion Resistance

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Customization

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

High-Strength Hot-Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, High Strength

NewsJul.30,2025