stainless star washer

Oct . 11, 2024 16:35 Back to list

stainless star washer

Understanding Stainless Steel Star Washers An Essential Component in Fastening Applications

When it comes to fastening applications, every component plays a vital role in ensuring that assemblies remain secure and reliable. Among these components, the stainless steel star washer stands out for its unique design and functional advantages. This article delves into the characteristics, benefits, and applications of stainless steel star washers, highlighting why they are essential in various industries.

What is a Star Washer?

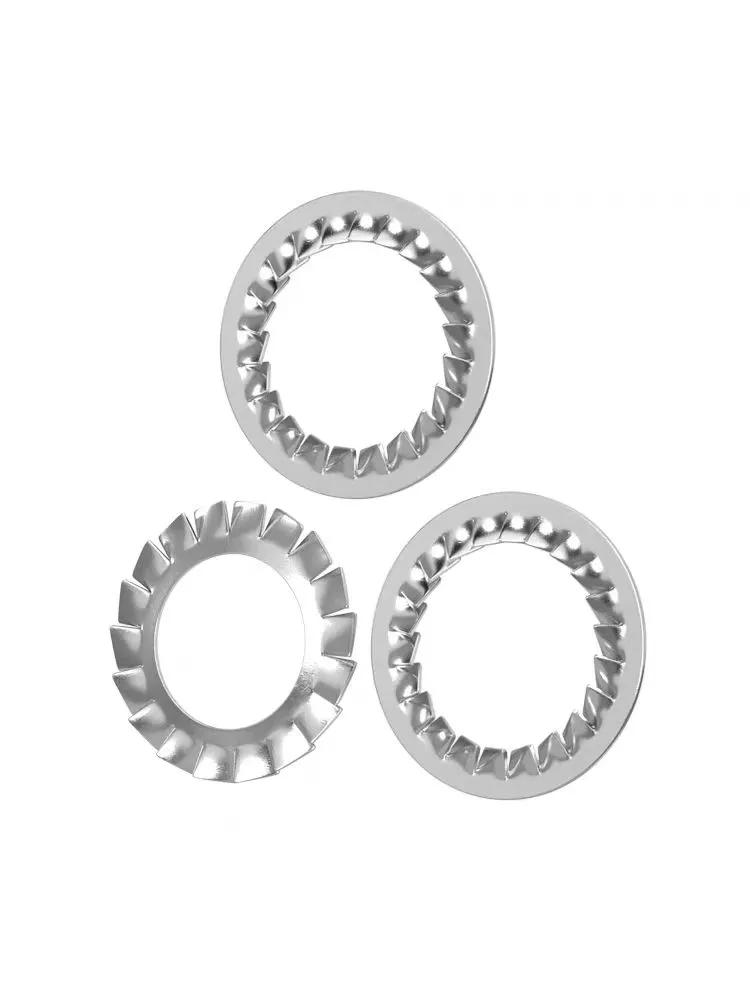

A star washer, often referred to as a tooth washer or serrated washer, features a series of prongs or teeth that penetrate the surface of the material when compressed. This design helps to ensure a firm grip and is primarily used to prevent loosening due to vibration or motion. Star washers come in different sizes and shapes, but stainless steel versions are particularly favored due to their corrosion resistance and durability.

Characteristics of Stainless Steel Star Washers

Stainless steel star washers are made from a high-quality alloy that offers exceptional resistance to rust and corrosion. They usually come in various grades, with 304 and 316 being the most common. Grade 304 stainless steel is known for its good corrosion resistance and formability, while Grade 316 offers higher resistance, particularly in chloride environments, making it suitable for marine applications.

The design of star washers involves multiple sharp teeth that dig into the surface of the material they are in contact with. This ensures that the washer stays in place and provides a reliable locking mechanism. The elasticity of stainless steel also allows the washer to maintain its gripping capability over time, even under fluctuating loads.

Benefits of Stainless Steel Star Washers

1. Corrosion Resistance One of the primary benefits of stainless steel is its resistance to corrosion. Unlike regular steel washers, stainless steel star washers will not rust, making them ideal for outdoor applications and environments exposed to moisture, chemicals, or salt.

stainless star washer

2. Vibration Resistance The unique design of star washers allows them to maintain tight connections despite vibrations. This is particularly important in automotive, aerospace, and machinery applications, where loosening fasteners can lead to significant failures.

3. Load Distribution The star shape enables better load distribution across the surface area, reducing the risk of damage to sensitive components or materials. This characteristic is essential in applications where pressure is evenly transferred.

4. Versatility Stainless steel star washers can be used in various applications, from automotive to construction, electronics, and machinery. Their adaptability makes them a popular choice among engineers and manufacturers.

5. Cost-Effective While stainless steel may be more expensive than its carbon steel counterpart, the long-term benefits such as longevity, reduced maintenance costs, and improved safety make it a cost-effective solution.

Applications of Stainless Steel Star Washers

Stainless steel star washers find applications across various industries, including

- Automotive Used in fasteners and electrical connections to prevent loosening due to engine vibrations. - Electronics In devices where secure connections are critical, star washers help maintain integrity over time. - Construction Used in structural applications where a strong hold is required under load. - Marine Their corrosion resistance makes them suitable for boat assemblies and equipment exposed to salty air and water.

Conclusion

In conclusion, stainless steel star washers are more than just a small component in the world of engineering; they are critical players in the reliability and safety of various applications. Their unique design and material properties make them indispensable in industries that require secure, long-lasting fastening solutions. Understanding their benefits and applications can assist engineers and manufacturers in selecting the right components for their projects, ultimately leading to more robust and reliable products.

Latest news

-

Premium Fasteners Manufacturer | AI-Driven Solutions

NewsAug.01,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | High Strength, Corrosion Resistance

NewsAug.01,2025

-

High-Strength Hot Dip Galvanized Bolts - LongZe | Corrosion Resistance, Custom Sizes

NewsAug.01,2025

-

Best Self Tapping Screws for Drywall - Fast & Secure Installation

NewsJul.31,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&Customization

NewsJul.31,2025

-

Hot Dip Galvanized Bolts-Hebei Longze Metal Products|Corrosion Resistance&High Strength

NewsJul.31,2025