Spring Washers and Flat Washers - Essential Fasteners for Every Application

Sep . 06, 2024 11:31 Back to list

Spring Washers and Flat Washers - Essential Fasteners for Every Application

Understanding Spring Washers and Flat Washers Their Importance and Applications

Washers are vital components in numerous mechanical assemblies, serving various purposes, from load distribution to preventing loosening of fasteners. Two common types are spring washers and flat washers. While both serve essential roles in fastening applications, they have distinct features and functions that make them suitable for different scenarios.

Flat Washers

Flat washers are simple, disc-shaped devices that are typically made from steel, plastic, or other materials. Their primary function is to distribute the load of a threaded fastener, such as a bolt or a screw, over a larger area. This helps to prevent damage to the material being fastened, reduces the risk of loosening, and provides a stable base for the fastener. Flat washers come in various sizes and thicknesses, allowing designers and engineers to select the appropriate type for their specific application.

In many cases, flat washers are used in conjunction with lock washers or other locking mechanisms to enhance the reliability of the joint. They are an essential component in applications ranging from construction to manufacturing, automotive, and household repairs. Their simplicity and effectiveness make them a popular choice in nearly any assembly requiring fasteners.

Spring Washers

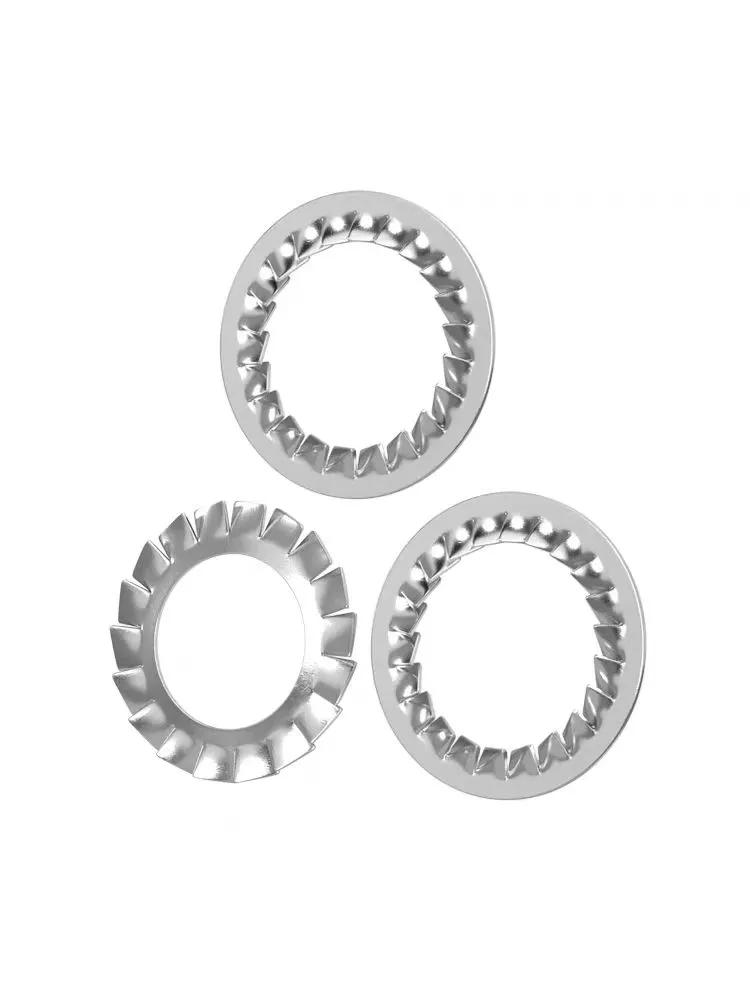

In contrast, spring washers are designed with a particular purpose in mind to provide elasticity and maintain tension in a bolted joint. These washers are typically made from high-carbon steel or other resilient materials and are engineered with a specific shape to allow for flexibility. They can come in various forms, such as conical, wave, or split washers, each offering different degrees of spring effect.

spring washers and flat washers

The primary role of a spring washer is to absorb vibrations and prevent loosening that can occur due to repeated motion or dynamic loading. This feature makes them especially valuable in applications such as machinery, automotive components, and heavy equipment, where movements can cause standard fasteners to loosen over time. By maintaining a constant load, spring washers help ensure that components remain securely fastened.

Applications and Advantages

The choice between spring washers and flat washers often hinges on the specific requirements of an application. Flat washers are ideal for distributing loads where fasteners are subjected to static forces, while spring washers excel in situations that experience vibrations or oscillating forces.

Using the right type of washer can lead to significant advantages, including improved safety, increased durability, and reduced maintenance costs. For instance, in automotive applications, using a spring washer can prevent failure under the dynamic conditions experienced by engine components, thereby enhancing reliability and longevity.

Conclusion

In summary, both spring washers and flat washers play crucial roles in ensuring the integrity and functionality of mechanical assemblies. Understanding the differences between these two types of washers allows engineers, technicians, and DIY enthusiasts to make informed decisions when selecting fasteners for their specific needs. With the right choice, one can achieve reliable, long-lasting connections that stand the test of time, ensuring the safe operation of machines and structures across various industries. Whether you’re securing a simple household fixture or assembling complex machinery, selecting the appropriate washer is an essential step in achieving success.

Latest news

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Customization

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

High-Strength Hot-Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, High Strength

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance, Grade 8.8

NewsJul.30,2025