slotted steel channel

Nov . 21, 2024 05:35 Back to list

slotted steel channel

Understanding Slotted Steel Channels Applications and Benefits

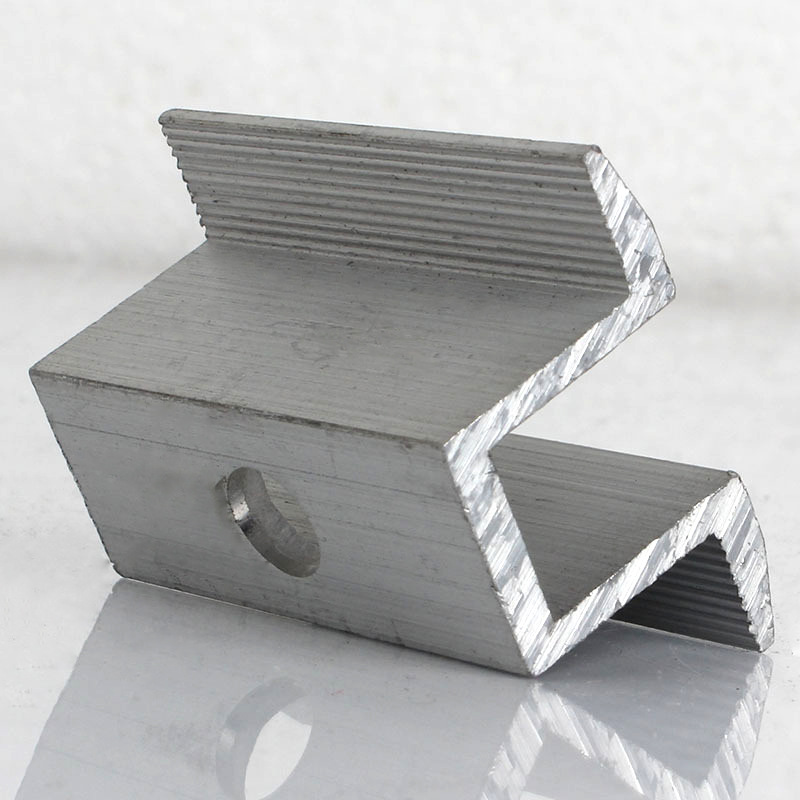

Slotted steel channels have become a staple in construction and manufacturing due to their versatility and strength. These channels are essentially U-shaped steel pieces with strategically placed slots along their length, allowing for the easy attachment of various components. The design not only enhances their functionality but also reduces installation time and labor costs, making them a preferred choice for many applications.

Design and Composition

Slotted steel channels are typically made from high-quality steel, which provides excellent durability and load-bearing capabilities. The slots in the channel can vary in size and spacing, depending on the specific needs of a project. This flexibility allows engineers and architects to customize the channel to suit their design requirements. The channels can be galvanized or coated to prevent rust and corrosion, thereby extending their lifespan, especially in outdoor applications.

Applications

One of the primary applications of slotted steel channels is in the construction of frameworks and support structures. They are widely used in building frames, shelving systems, and racking solutions. Their slotted design allows for easy adjustments during installation, enabling users to reposition components without the need for cutting or modifying the channel itself.

In industrial settings, slotted channels are often used to create equipment mounting systems, conveyor supports, and even safety barriers. The ability to attach various brackets and fittings directly into the slots provides a convenient way of adapting the setup to changing operational needs.

slotted steel channel

Slotted steel channels are also prevalent in electrical and plumbing applications. They serve as cable trays or conduit supports, providing a robust support mechanism for running electrical wires or piping throughout a facility. Their design helps manage and organize these essential systems while maintaining accessibility for future maintenance and upgrades.

Advantages

The advantages of using slotted steel channels are numerous. First and foremost, their adaptability makes them perfect for a dynamic work environment where changes are frequent. The slotted design allows for quick modifications, reducing downtime associated with reconfiguring system layouts.

Moreover, slotted channels are lightweight compared to other structural members, which simplifies handling and installation. Despite their light weight, they do not compromise on strength, capable of supporting significant loads while being easy to transport and install.

Another notable benefit is cost-effectiveness. The reduction in labor time and ease of installation contributes to overall project savings, making slotted steel channels a budget-friendly option for builders and manufacturers.

Conclusion

In summary, slotted steel channels are an invaluable component in modern construction and manufacturing. Their innovative design enhances functionality, allowing for adaptable and efficient solutions across various industries. Whether for structural support, equipment mounting, or cable management, the robustness and versatility of slotted steel channels make them an essential choice for anyone looking to optimize their design and installation processes. As industries continue to evolve and requirements shift, these channels will undoubtedly remain relevant and widely used for years to come.

Latest news

-

Hot Dip Galvanized Bolts-About LongZe|High Strength, Corrosion Resistance

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Customization

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

High-Strength Hot-Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, High Strength

NewsJul.30,2025