Understanding the Benefits and Applications of Self-Tapping Structural Screws in Construction

Nov . 19, 2024 17:57 Back to list

Understanding the Benefits and Applications of Self-Tapping Structural Screws in Construction

Understanding Self-Tapping Structural Screws An Essential Component in Modern Construction

In the world of construction and manufacturing, the choice of fasteners plays a pivotal role in ensuring the integrity and longevity of structures. Among various types of fasteners, self-tapping structural screws have gained significant attention due to their unique design and functionality. These screws are not just ordinary fasteners; they are specially designed to facilitate fastening without the need for pre-drilled holes, making them an invaluable asset in many construction projects.

What are Self-Tapping Structural Screws?

Self-tapping structural screws are designed to create their own thread when driven into materials, eliminating the need for separate drilling. This feature makes them particularly advantageous in various applications, such as wood-to-wood or metal-to-metal fastening. The head and shank of these screws are engineered to withstand high levels of torque and shear stress, giving them superior holding power compared to conventional screws. Generally, these screws are utilized in applications where the load-bearing capacity is crucial, such as in framing, decking, and metal connections.

The Advantages of Self-Tapping Structural Screws

1. Time Efficiency One of the primary advantages of self-tapping structural screws is the significant reduction in installation time. Because they do not require pre-drilling, contractors can save time and labor costs, translating into faster project completion.

2. Reduced Risk of Damage Pre-drilling can sometimes lead to inadvertent damage to the materials, such as splitting wood or misaligning metal. Self-tapping screws mitigate this risk, providing a cleaner installation method.

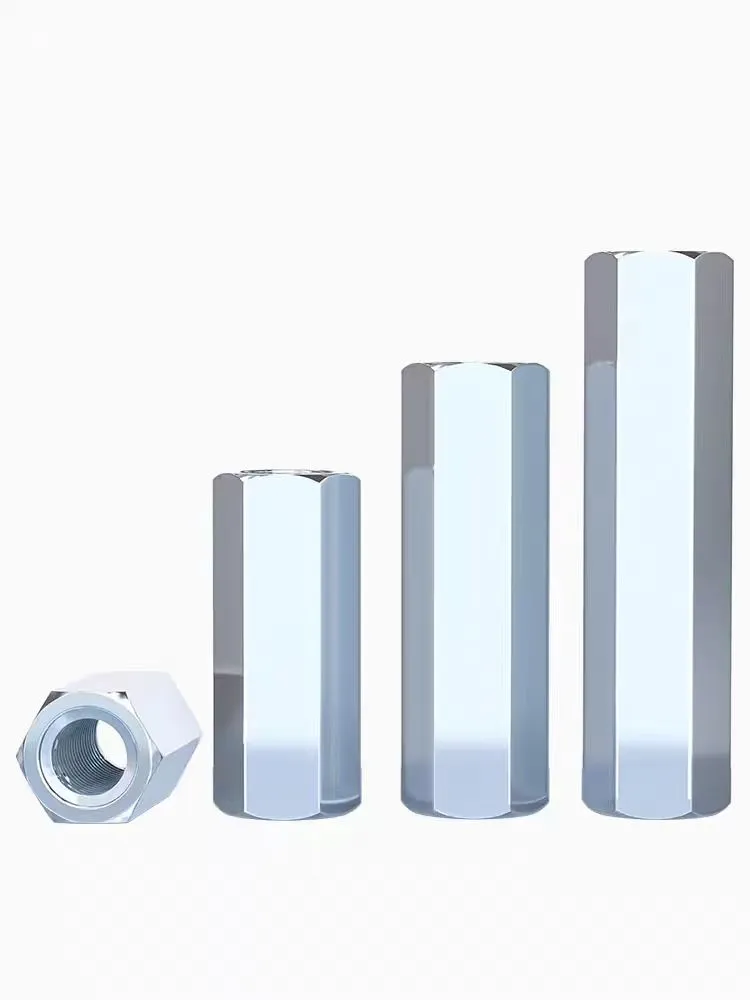

self tapping structural screws

3. Enhanced Strength and Stability These screws are engineered to provide exceptional holding power. Their design allows for deep engagement in the material, delivering superior resistance to withdrawal and shear forces. This strength is particularly important in structural applications where safety is paramount.

4. Versatility Self-tapping structural screws are versatile and can be used with a variety of materials, including wood, steel, and composites. This adaptability makes them suitable for a wide range of construction and manufacturing applications.

5. Material Compatibility Many self-tapping screws are treated to resist corrosion and wear, making them ideal for exterior applications or in environments where exposure to moisture and chemicals is a concern.

Installation Considerations

While self-tapping structural screws simplify the fastening process, proper installation techniques are critical to achieving optimal results. Using the correct screw size and type for the given application is essential, as is ensuring an appropriate torque level during installation. Over-torquing can lead to stripping the threads or breaking the screw, while under-torquing may result in inadequate holding power. Additionally, selecting the appropriate pilot hole size (if specified) can further enhance the performance of the screws.

Conclusion

Self-tapping structural screws represent a remarkable advancement in fastening technology that meets the demands of modern construction and manufacturing. Their ability to create their own threads allows for quick and efficient installation while providing unmatched strength and stability. Whether used in residential construction, industrial settings, or specialized applications, these screws continue to prove their worth. As the industry evolves and new materials are introduced, the role of self-tapping structural screws will likely become even more significant, reinforcing their status as indispensable tools for builders and manufacturers alike. As we embrace innovations in engineering and design, understanding and utilizing such fasteners will remain a cornerstone of effective construction practices.

Latest news

-

High-Strength Hot-Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, High Strength

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance, Grade 8.8

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance,High Strength

NewsJul.29,2025

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze Metal Products Manufacturing Co., Ltd.|corrosion resistance&high strength

NewsJul.29,2025