Understanding Self-Tapping Shoulder Screws and Their Applications in Various Industries

Oct . 31, 2024 15:19 Back to list

Understanding Self-Tapping Shoulder Screws and Their Applications in Various Industries

Understanding Self-Tapping Shoulder Screws

Self-tapping shoulder screws are specialized fasteners that play an essential role in various applications across different industries. Unlike regular screws, these unique fasteners are designed to create their own thread in materials, offering enhanced installation efficiency and reliability. Their unique structure comprises a shoulder, which provides a solid support surface, and a threaded shaft that allows them to self-tap into materials, making them ideal for numerous engineering and construction applications.

Understanding Self-Tapping Shoulder Screws

Self-tapping shoulder screws can be made from various materials, including stainless steel, brass, and plastic, which makes them suitable for different environments. For instance, stainless steel self-tapping screws are particularly resistant to corrosion, making them ideal for outdoor or marine applications. On the other hand, plastic options are lightweight and resistant to chemical exposure, which can be crucial in certain industrial settings.

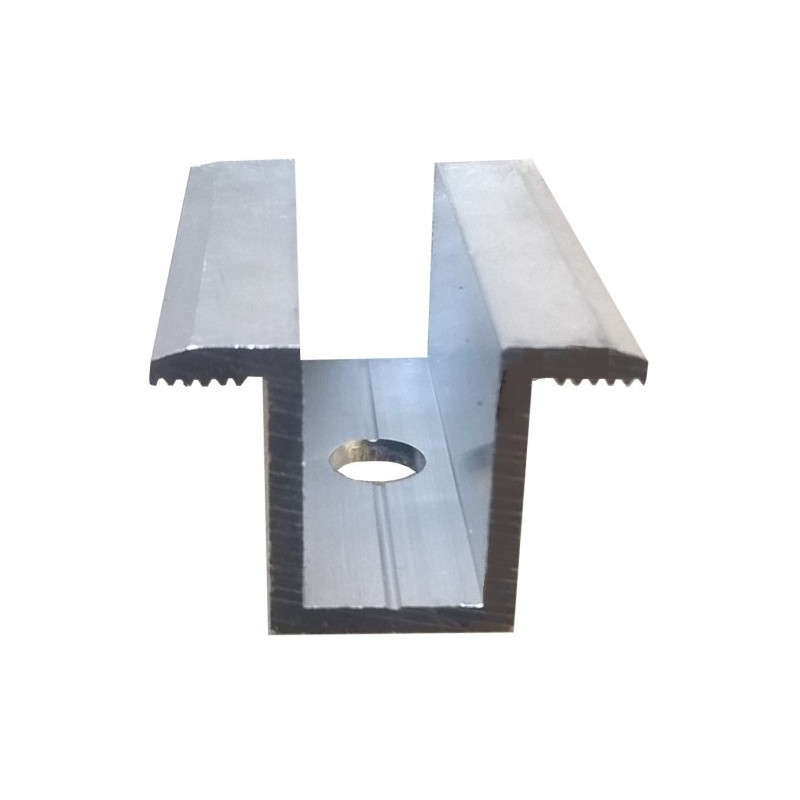

self tapping shoulder screw

When choosing self-tapping shoulder screws for a project, it is essential to consider factors such as material compatibility, load requirements, and environmental conditions. The size and length of the screw also play a significant role in ensuring the integrity of the assembly. Proper torque specifications should be followed during installation to avoid damaging the material or the screw itself.

In addition to their use in manufacturing and construction, self-tapping shoulder screws have applications in the electronics industry, automotive assembly, and furniture manufacturing. Their versatility and reliability make them a preferred choice among engineers and manufacturers alike.

In conclusion, self-tapping shoulder screws are a vital component in many industrial applications. Their ability to self-tap into materials combined with the functionality provided by the shoulder makes them an efficient and effective fastening solution. When employed correctly, they enhance assembly processes and improve the durability of the finished product, solidifying their place in modern manufacturing practices. Understanding their features and applications can help industries leverage their potential, ensuring projects are completed with precision and efficiency.

Latest news

-

High-Strength Hot-Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, High Strength

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance, Grade 8.8

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance,High Strength

NewsJul.29,2025

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze Metal Products Manufacturing Co., Ltd.|corrosion resistance&high strength

NewsJul.29,2025