Advantages of Using Self-Tapping Screws for Efficient Assembly and Fastening Applications

Nov . 07, 2024 14:43 Back to list

Advantages of Using Self-Tapping Screws for Efficient Assembly and Fastening Applications

The Versatility of Self-Tapping Cap Screws

Self-tapping cap screws are a marvel of engineering, designed to simplify assembly and fastening in various applications. Unlike traditional screws, which require pre-drilled holes, self-tapping screws can create their own threads in the material they are driven into. This unique capability makes them an essential tool in industries ranging from construction and automotive to electronics and furniture manufacturing.

What Are Self-Tapping Cap Screws?

Self-tapping cap screws are fasteners that integrate the functionality of a cap screw with the self-threading feature. They are typically characterized by a flat or rounded head and a sharp, pointed tip that allows the screw to penetrate materials without the need for additional tools. The cap head serves to provide a larger surface area, distributing the load more evenly and offering a neat finish that enhances the aesthetic of the assembly.

These screws are made from various materials, including stainless steel, carbon steel, and brass, ensuring they can withstand different environmental conditions while providing strength and durability. Their design significantly reduces assembly time and labor costs, making them ideal for mass production.

Applications of Self-Tapping Cap Screws

1. Construction In the construction industry, self-tapping cap screws are commonly used to secure metal and wood components. Their ability to drive into different materials makes them extremely versatile, allowing for applications ranging from framing and roofing to securing structural elements.

2. Automotive The automotive industry benefits greatly from self-tapping cap screws, especially in the assembly of vehicle parts. They are used to fasten everything from body panels to engine components. Their reliable holding power and resistance to vibration make them indispensable in maintaining vehicle integrity.

3. Electronics In the electronics realm, self-tapping cap screws help secure components within devices such as computers, appliances, and more. Their precision fit ensures that electronic components are held securely in place, which is vital for the proper functioning of these devices.

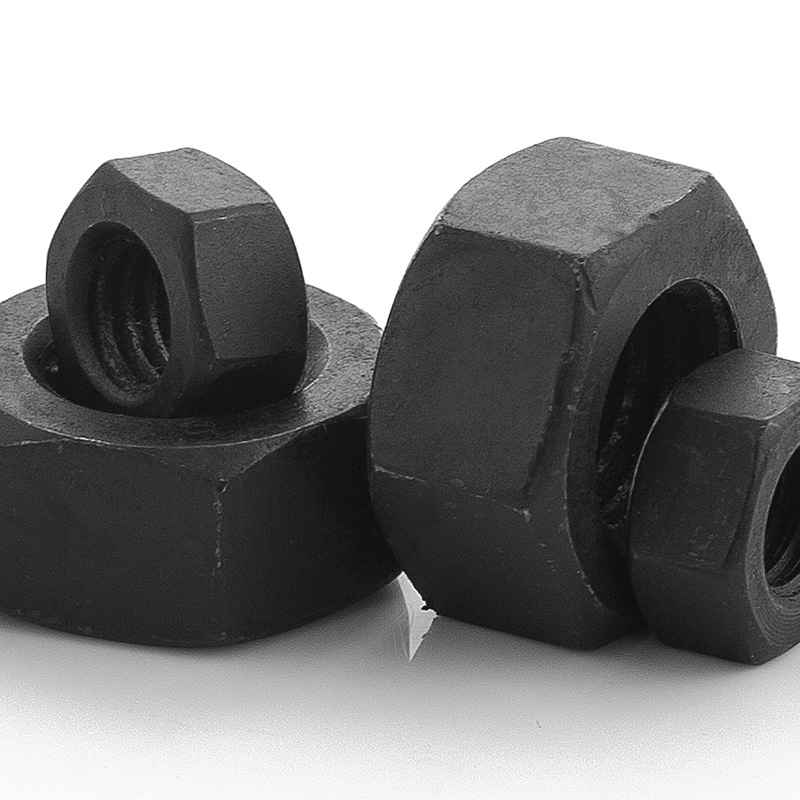

self tapping cap screws

4. Furniture The furniture industry also utilizes self-tapping cap screws for easy assembly. Many modern flat-pack furniture designs include these screws, allowing consumers to assemble their furniture quickly and efficiently without the need for specialized tools.

Advantages of Self-Tapping Cap Screws

The advantages of using self-tapping cap screws are numerous

- Time Efficiency Since these screws do not require pre-drilled holes, they save considerable time during the assembly process. This is especially beneficial in production environments where efficiency is key.

- Cost-Effectiveness The reduction of labor and the elimination of the need for additional tools contribute to lower overall costs in manufacturing and construction projects.

- Improved Strength Self-tapping cap screws provide better fatigue strength and can handle various loads, making them ideal for demanding applications.

- Aesthetic Appeal The cap design allows for a more finished look compared to standard screws, which can enhance the overall appearance of the final product.

Conclusion

In summary, self-tapping cap screws represent a significant advancement in fastening technology, combining ease of use, cost-effectiveness, and functionality. Their widespread applications across various industries underscore their importance in modern manufacturing and construction. As technology advances and new materials are developed, the role of self-tapping cap screws will undoubtedly continue to evolve, further solidifying their place as a critical component in the assembly of countless products. Whether in a workshop, factory, or at home, these screws are an essential tool for any DIY enthusiast or professional tradesperson looking to streamline their projects with reliability and efficiency.

Latest news

-

Hot Dip Galvanized Bolts - Hebei Longze | High Strength, Corrosion Resistance

NewsAug.01,2025

-

High-Strength Hot Dip Galvanized Bolts - LongZe | Corrosion Resistance, Custom Sizes

NewsAug.01,2025

-

Best Self Tapping Screws for Drywall - Fast & Secure Installation

NewsJul.31,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&Customization

NewsJul.31,2025

-

Hot Dip Galvanized Bolts-Hebei Longze Metal Products|Corrosion Resistance&High Strength

NewsJul.31,2025

-

Hot Dip Galvanized Bolts-About LongZe|High Strength, Corrosion Resistance

NewsJul.30,2025