self drilling self tapping

Nov . 14, 2024 16:28 Back to list

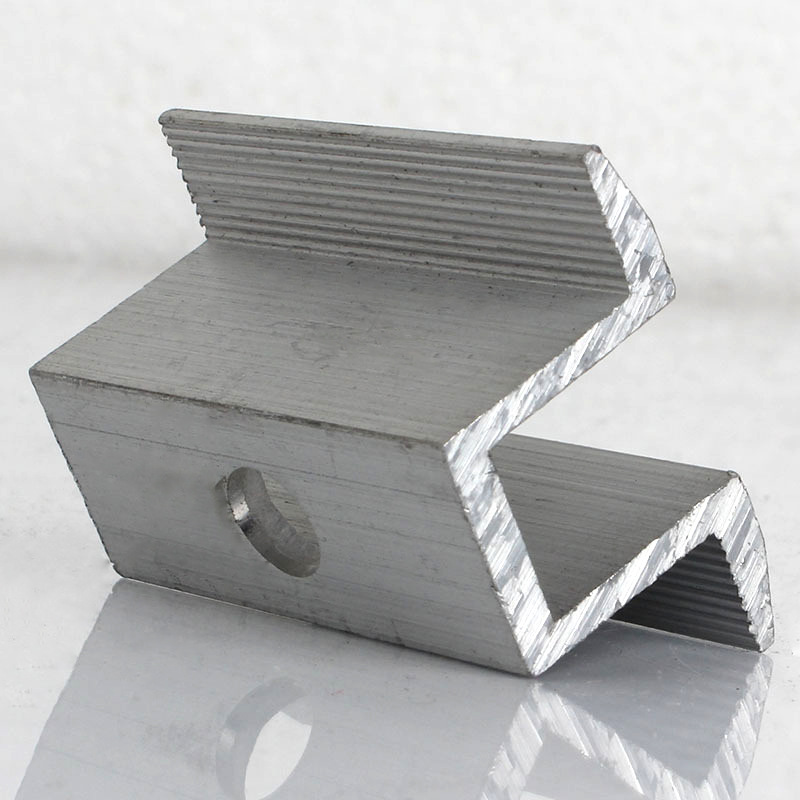

self drilling self tapping

Understanding Self-Drilling and Self-Tapping Screws A Comprehensive Guide

In the realm of construction and manufacturing, fastening systems play a crucial role in ensuring the integrity and durability of structures and products. Among these systems, self-drilling and self-tapping screws have gained significant popularity due to their efficiency and versatility. This article will delve into the characteristics, advantages, applications, and distinctions between self-drilling and self-tapping screws.

What are Self-Drilling and Self-Tapping Screws?

Self-drilling screws, often referred to as drywall screws or Tek screws, are designed with a sharp, drill-like tip that allows the screw to create its own hole as it is driven into various materials. This feature eliminates the need for a pilot hole, simplifying the installation process significantly. These screws are typically used in metal-to-metal applications or when fastening metal to wood.

On the other hand, self-tapping screws are designed with a pointed tip that allows them to cut their own thread into pre-drilled holes. Unlike self-drilling screws, self-tapping screws may require an initial pilot hole when working with harder materials. This type of screw is commonly used in wood, plastic, and sometimes metal applications, depending on the specific design and coating of the screw.

Advantages of Self-Drilling Screws

1. Time Efficiency The primary advantage of self-drilling screws is the reduction in installation time. Their ability to drill through materials means that workers spend less time preparing holes, which translates to faster project completion.

3. Strength and Stability These screws are specifically engineered for robust applications, providing excellent holding power and resistance to loosening over time. This quality is essential in constructions where structural integrity is paramount.

4. Versatility Self-drilling screws are available in various sizes, materials, and coatings, making them suitable for a wide range of applications, from roofing and siding to automotive and industrial manufacturing.

Advantages of Self-Tapping Screws

self drilling self tapping

1. Material Compatibility Self-tapping screws are highly versatile and can be used in various materials, including wood, metal, and plastic. This adaptiveness makes them popular among builders who work with different substrates.

2. Reduced Risk of Material Splitting When used properly, self-tapping screws can minimize the risk of damaging the material, especially in the case of wood, where traditional screws might cause splitting.

3. Cost-Effectiveness Self-tapping screws are often less expensive than self-drilling screws, making them a budget-friendly option for projects that do not require extensive drilling capabilities.

4. Variety of Designs Available in numerous designs, self-tapping screws can cater to specific needs, such as those with unique head shapes or materials that provide superior corrosion resistance.

Key Differences

While self-drilling and self-tapping screws may seem similar, their functional differences are notable. The primary distinction lies in their operation self-drilling screws can create holes without any prior drilling, whereas self-tapping screws may require a pre-drilled hole depending on the application and material. Moreover, self-drilling screws are generally better suited for projects involving metals, while self-tapping screws are versatile enough for wood, plastic, and light metals.

Applications in Various Industries

Both types of screws have found applications across different sectors. In construction, self-drilling screws are favored for their speed and ease when attaching heavy materials like steel framing. In contrast, self-tapping screws are often employed in furniture assembly and electronics due to their compatibility with a wide range of materials and ease of use.

Conclusion

Self-drilling and self-tapping screws are indispensable tools in the construction and manufacturing industries. Understanding their unique characteristics, advantages, and applications helps to make informed choices when selecting the appropriate fastening system for a project. With ongoing advancements in fastening technologies, these screws are likely to remain essential components in building projects and product assembly, contributing to safer, more efficient construction practices. Whether you're a seasoned professional or an enthusiastic DIYer, harnessing the right fastening solution can make all the difference in achieving optimal results.

Latest news

-

High-Strength Hot Dip Galvanized Bolts - LongZe | Corrosion Resistance, Custom Sizes

NewsAug.01,2025

-

Best Self Tapping Screws for Drywall - Fast & Secure Installation

NewsJul.31,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&Customization

NewsJul.31,2025

-

Hot Dip Galvanized Bolts-Hebei Longze Metal Products|Corrosion Resistance&High Strength

NewsJul.31,2025

-

Hot Dip Galvanized Bolts-About LongZe|High Strength, Corrosion Resistance

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Customization

NewsJul.30,2025