Galvanized Self-Drilling Screws for Enhanced Durability and Easy Installation Applications

Dec . 05, 2024 02:49 Back to list

Galvanized Self-Drilling Screws for Enhanced Durability and Easy Installation Applications

The Evolution and Importance of Self-Drilling Screws in Construction

In the dynamic world of construction and manufacturing, the efficiency of fastening methods has greatly influenced the quality and longevity of structural components. Among various fastening systems, self-drilling screws, particularly galvanized ones, stand out due to their unique features and applications.

Understanding Self-Drilling Screws

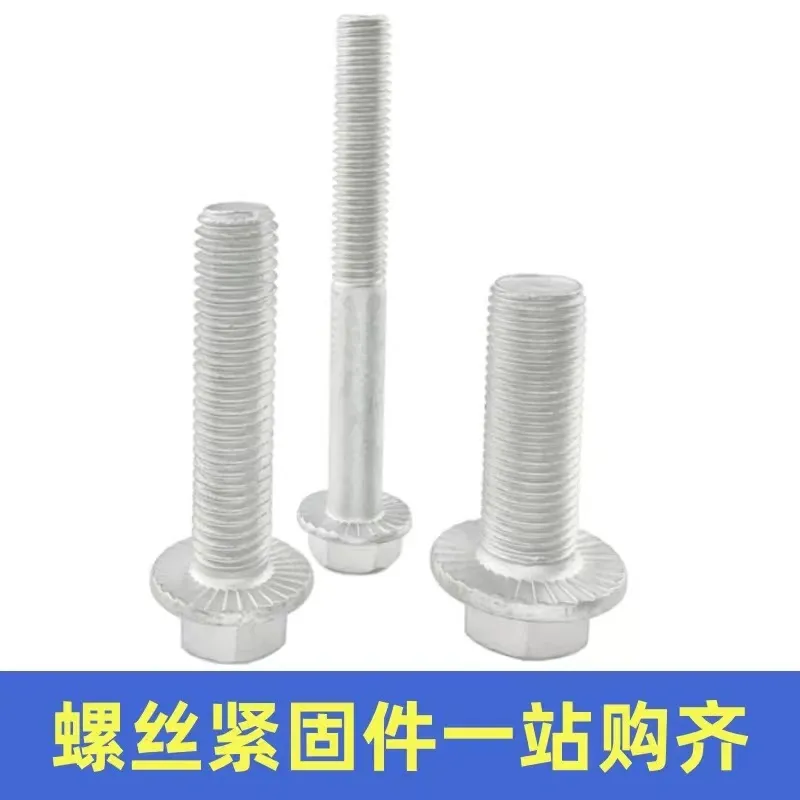

Self-drilling screws, also known as self-tapping screws, come equipped with a drill bit tip that enables them to drill through materials such as metal and wood, eliminating the need for pre-drilling. This characteristic not only saves time but also increases productivity on construction sites. When it comes to galvanization, it involves the process of coating steel with zinc to enhance its resistance to corrosion. This is crucial for screws used outdoors or in environments exposed to moisture, chemicals, or extreme temperatures.

Advantages of Galvanized Self-Drilling Screws

The combination of self-drilling and galvanized features provides several advantages

1. Corrosion Resistance Galvanization protects the steel screws from rust and degradation, prolonging their lifespan, especially in harsh environments. Construction projects near coastal areas or in regions with high humidity significantly benefit from this feature.

2. Ease of Installation The self-drilling design allows for quick and efficient installation, reducing labor costs and the need for additional tools. This efficiency makes them a favorite among contractors who focus on speed without compromising quality.

3. Versatile Applications Galvanized self-drilling screws are suitable for a variety of materials, including wood, sheet metal, and composite materials. This versatility makes them ideal for diverse applications such as metal roofing, siding, HVAC installations, and wood construction.

self drilling screws galvanized

4. Strong Hold The unique threading and the drill bit design provide a secure and tight fit, ensuring that the materials remain firmly attached even under significant stress or movement. This strength is vital for structures where integrity is paramount.

Industry Applications

Galvanized self-drilling screws have found their place in numerous industries. In the construction sector, they are commonly used in roofing systems, where they secure metal panels and withstand high winds and various weather conditions. Additionally, they are utilized in the assembly of pre-engineered metal buildings, which are increasingly popular due to their cost-effectiveness and efficiency in construction.

Moreover, in the automotive and aerospace industries, self-drilling screws play a crucial role in assembling parts and components—offering reliable and sturdy connections. Their usage in manufacturing processes extends to products such as furniture and appliances, where quick assembly is a key factor.

Environmental Considerations

As sustainability becomes a central theme in construction practices, the use of galvanized self-drilling screws aligns well with this movement. The longevity of these screws reduces the frequency of replacements, thus minimizing waste over time. Additionally, their recyclability supports eco-friendly practices within the industry.

Using self-drilling screws also contributes to efficiency in energy use. The expedited installation process leads to reduced labor hours, which translates to lower energy consumption during building projects. Consequently, contractors can complete projects faster, reducing downtime and overall resource usage.

Conclusion

In summary, galvanized self-drilling screws are an essential component in modern construction and manufacturing. Their corrosion-resistant properties, ease of use, versatility, and strength make them indispensable tools across various industries. As construction trends evolve, the demand for efficient and reliable fastening solutions continues to grow, solidifying the position of self-drilling screws as a staple in the building toolkit. As we look to the future, the ongoing innovations in materials and design will undoubtedly further enhance their performance, paving the way for even more advanced applications in the ever-evolving construction landscape.

Latest news

-

High-Strength Hot-Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, High Strength

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance, Grade 8.8

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance,High Strength

NewsJul.29,2025

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze Metal Products Manufacturing Co., Ltd.|corrosion resistance&high strength

NewsJul.29,2025