self drilling screw 1

Dec . 10, 2024 07:14 Back to list

self drilling screw 1

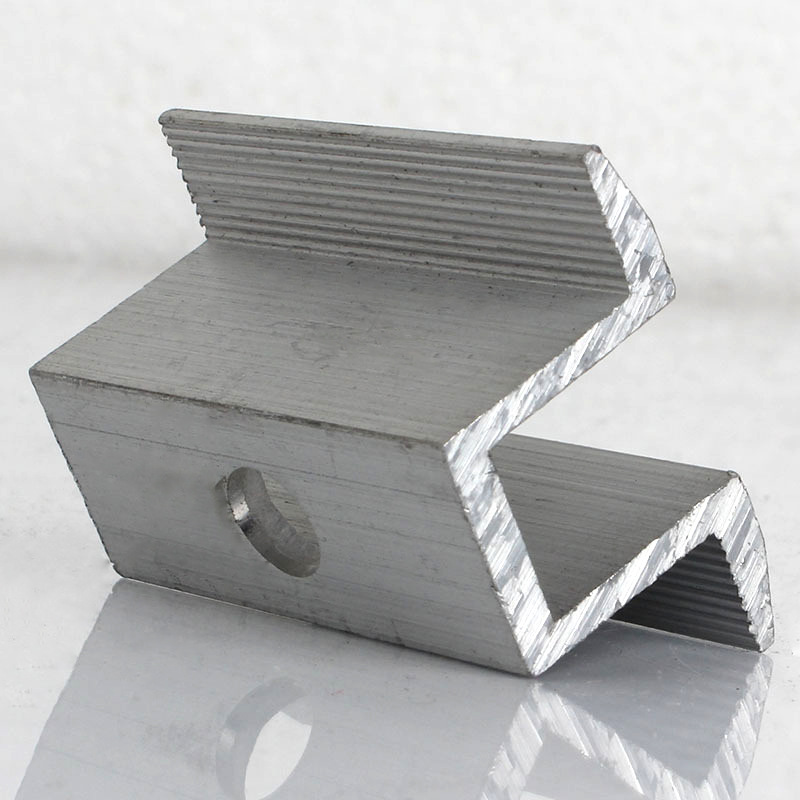

Understanding Self-Drilling Screws The Fastener of Choice in Modern Construction

In the realm of construction and manufacturing, fasteners play a significant role in ensuring the strength and durability of structures. Amongst the myriad of fastening options available, self-drilling screws stand out as a versatile and efficient choice. This article delves into the intricacies of self-drilling screws, discussing their design, application, and advantages.

What Are Self-Drilling Screws?

Self-drilling screws, often referred to as Tek screws or self-tappers, are designed with a sharp point and fluted shafts. This unique design allows them to create their own hole as they are driven into the material, eliminating the need for pre-drilling. This feature is particularly advantageous for construction professionals and DIY enthusiasts alike, as it significantly reduces installation time and effort.

Self-drilling screws come in a variety of sizes and materials. The most common materials include steel, stainless steel, and sometimes aluminum, catering to diverse applications. The choice of material and the coating (such as zinc or epoxy) plays a critical role in preventing corrosion, particularly in outdoor or harsh environments.

Applications in Construction

Self-drilling screws find extensive usage across several sectors including construction, automotive, and appliance manufacturing. One of their primary applications is in metal framing, where they securely fasten metal studs without the need for additional parts or fasteners. In roofing, self-drilling screws are employed to attach metal panels, ensuring a watertight seal that withstands the elements.

In addition to metal applications, self-drilling screws are also effective in wood and composite materials. Their versatility allows them to be used in wooden frameworks or furniture assembly, providing strong hold and structural integrity. The ability to produce a clean pilot hole means they can be driven near edges without splitting the material, thus enhancing their usability.

self drilling screw 1

Advantages of Self-Drilling Screws

1. Time-Efficiency The most significant benefit of using self-drilling screws is the time saved during installation. Traditional screws require pre-drilling, which can be labor-intensive and time-consuming. Self-drilling screws streamline the process, enabling quicker assembly and reducing labor costs.

2. Cost-Effectiveness Beyond the saved labor costs, self-drilling screws are often cost-effective in terms of the materials needed for a project. By eliminating the need for drill bits and additional fasteners, overall expenses can be significantly reduced.

3. Strong Mechanism The design of self-drilling screws allows for a superior grip and strength compared to standard screws. They maintain a tight fit and resist loosening over time, contributing to the longevity and safety of the constructed items.

4. Versatility As mentioned, these screws can be used in various materials, making them suitable for a wide range of projects. From roofing and siding to metal-to-metal connections and woodworking, their adaptability is a key attribute.

5. Reduced Risk of Damage Since self-drilling screws create their own holes, there is a lower risk of damage to the materials being joined. This aspect is particularly crucial in applications where aesthetics matter, as it helps maintain the integrity of the project appearance.

Conclusion

Self-drilling screws have revolutionized the fastening process in construction and manufacturing, proving themselves as superior tools for modern building needs. Their ability to self-tap into materials, facilitate speed, and minimize costs makes them a preferred choice among professionals. As construction practices continue to evolve, the reliance on innovative fasteners like self-drilling screws will only grow, reinforcing their vital role in the industry. Whether you're a seasoned contractor or a weekend DIY warrior, understanding the benefits and applications of these screws can greatly enhance the quality and efficiency of your work.

Latest news

-

Hot Dip Galvanized Bolts-About LongZe|High Strength, Corrosion Resistance

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Customization

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

High-Strength Hot-Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, High Strength

NewsJul.30,2025