oversized flange nuts

Dec . 15, 2024 16:57 Back to list

oversized flange nuts

Understanding Oversized Flange Nuts A Comprehensive Overview

In the world of industrial fasteners, oversized flange nuts have carved a niche for themselves, serving a variety of applications across different sectors. This article aims to delve into the characteristics, advantages, and applications of oversized flange nuts, providing insights into why they are an essential component in modern engineering.

What Are Oversized Flange Nuts?

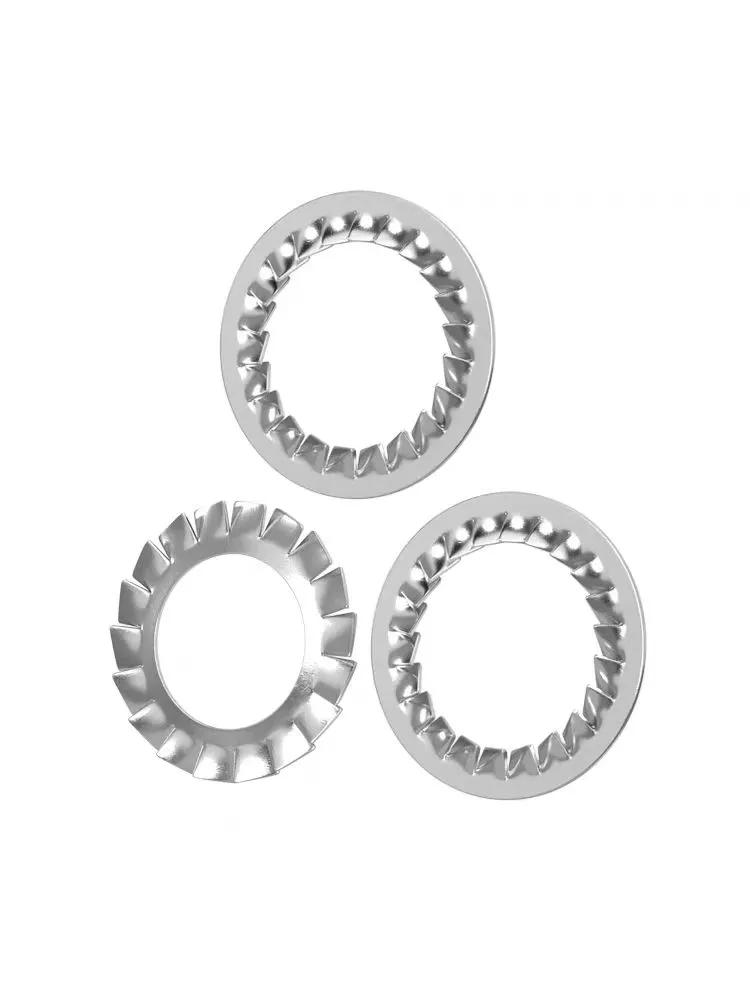

Oversized flange nuts are a type of nut that features a larger flange on one end than standard nuts. The flange serves two primary purposes it acts as a built-in washer, distributing the load over a larger area, and it helps to prevent the nut from loosening under vibrations and fluctuating loads. The added size of the flange offers enhanced contact with the mating surface, which can lead to improved stability and a lower likelihood of warping over time.

Key Characteristics

One of the defining characteristics of oversized flange nuts is their dimensions. The flange is significantly wider than that of standard nuts, which generally enhances their load-bearing capacity. Common materials used in the manufacture of these nuts include steel, stainless steel, and various alloys, offering a balance between strength, weight, and resistance to environmental factors such as corrosion. Sizes can vary from small to large, accommodating a wide range of bolt sizes.

Another crucial aspect is the thread type, which can be coarse or fine, depending on the application requirements. Selection of the right thread type and size is critical to ensure a proper pairing with the corresponding bolts, which ultimately affects the overall performance of the assembly.

Advantages of Oversized Flange Nuts

1. Enhanced Load Distribution The larger flange distributes the load more evenly, reducing the risk of deformation or damage to the material being fastened. This is particularly beneficial in applications where materials are soft or prone to scratching.

2. Improved Vibration Resistance The flange design helps to absorb vibrations, preventing the nut from loosening over time. This is especially important in mechanical systems that experience high levels of movement or shock.

oversized flange nuts

3. Simplified Installation Since oversized flange nuts combine the functions of a nut and a washer, they can simplify installation processes. This can lead to reduced assembly times and lower labor costs.

4. Corrosion Resistance Many oversized flange nuts are treated or manufactured from corrosion-resistant materials, making them suitable for harsh environments, including marine and industrial applications.

5. Versatility These nuts are adaptable for various applications, from construction to automotive industries, making them a popular choice for engineers and designers.

Applications of Oversized Flange Nuts

Oversized flange nuts are commonly used in a variety of fields, including

- Construction In building projects, these nuts are often utilized to secure heavy structures, ensuring stability and safety. - Automotive They are frequently employed in automotive manufacturing for securing components, particularly in areas vulnerable to vibrations. - Aerospace High-strength oversized flange nuts are critical in the aerospace industry, where they are used to hold together essential components that must endure dynamic forces. - Manufacturing Equipment Machines often require robust fastening solutions that can withstand intensive use, making oversized flange nuts an ideal choice.

Choosing the Right Flange Nut

When selecting oversized flange nuts for a specific application, it is vital to consider factors such as load requirements, environmental conditions, and compatibility with existing components. Engineers often refer to industry standards and specifications to ensure that the chosen nut meets safety and performance standards.

Conclusion

Oversized flange nuts play a crucial role in modern engineering and construction. Their unique design and benefits make them invaluable in applications that demand reliability and performance. As industries evolve and new challenges arise, the importance of these fasteners will likely continue to grow, solidifying their place as a critical component in various applications. Understanding their characteristics and advantages allows engineers and designers to leverage them effectively, ensuring safety and functionality in their projects.

Latest news

-

Hot Dip Galvanized Bolts-About LongZe|High Strength, Corrosion Resistance

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Customization

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

High-Strength Hot-Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, High Strength

NewsJul.30,2025