nut hex flange

Dec . 14, 2024 00:43 Back to list

nut hex flange

Understanding the Nut and Hex Flange Key Components in Fastening Technology

In the world of mechanical engineering and construction, the importance of reliable fastening systems cannot be overstated. Among the various components utilized in these systems, the nut and hex flange stand out as essential elements that contribute significantly to the overall integrity of assemblies. In this article, we will explore the design, functionality, applications, and advantages of the nut and hex flange, and why they are critical in industries ranging from automotive to aerospace.

What is a Nut?

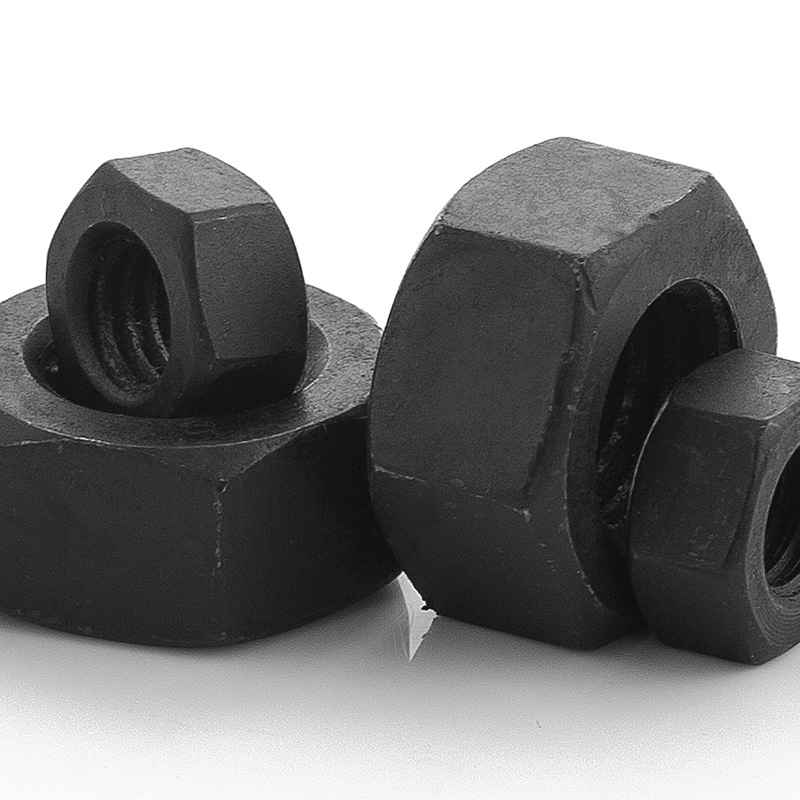

A nut is a hexagonal block of metal or another material with a hole in the center, designed to fit over a bolt. The internal thread of the nut interacts with the external thread of the bolt, allowing it to secure components by creating a clamping force. The traditional hex nut is characterized by its six-sided shape, providing a flat surface for tools such as wrenches or sockets to easily grip.

The Hex Flange Nut

The hex flange nut, on the other hand, is a variation that combines the traditional hex nut design with an integrated flange. The flange is essentially a wider, circular base that extends from one side of the nut. This design not only increases the surface area but also helps distribute the load over a larger area when the nut is tightened. This feature is particularly valuable in applications where thin materials or softer substrates are involved, as it minimizes the risk of damage during installation.

Key Advantages of Hex Flange Nuts

1. Load Distribution The primary advantage of the hex flange nut is its ability to distribute the load across a larger surface area. This reduces the chances of material deformation and increases the fastening integrity.

nut hex flange

2. Elimination of Washers In many applications, the flange eliminates the need for additional washers, simplifying the assembly process and reducing component count. This can lead to cost savings and fewer potential points of failure.

3. Prevention of Loosening The design of the hex flange nut often includes additional features like serrations or a locking mechanism. These enhancements help maintain torque and prevent loosening due to vibration or dynamic loads.

4. Versatility Hex flange nuts are available in various sizes, materials, and thread configurations, making them suitable for a wide range of applications. From automotive assemblies to heavy machinery, their adaptability is one of their greatest strengths.

Applications in Industry

Hex flange nuts are widely used in a variety of industries. In the automotive sector, for instance, they are employed to secure components such as engine mounts, suspension parts, and chassis assemblies. The increased resistance to loosening and enhanced load distribution are critical in environments subject to high levels of vibration and stress.

Similarly, in construction, hex flange nuts can be found securing steel beams, bridges, and other structures where safety and reliability are paramount. Their ability to withstand harsh conditions makes them suitable for outdoor fabrication and installations, where exposure to the elements can compromise other fastening methods.

Conclusion

In conclusion, the nut and hex flange play a vital role in fastening technology across various industries. Their distinct design offers multiple advantages, including enhanced load distribution, elimination of additional components, and improved resistance to loosening. As the demand for reliable and durable fastening solutions continues to grow, understanding the function and applications of these components becomes increasingly essential for engineers and manufacturers alike. Whether in the automotive industry, construction, or beyond, the hex flange nut proves to be an indispensable tool in ensuring the safety and integrity of mechanical assemblies.

Latest news

-

Hot Dip Galvanized Bolts-About LongZe|High Strength, Corrosion Resistance

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Customization

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

High-Strength Hot-Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, High Strength

NewsJul.30,2025