mid clamp

Nov . 17, 2024 14:10 Back to list

mid clamp

Understanding Mid Clamp A Critical Component in Electrical Systems

In the realm of electrical engineering, certain components play pivotal roles in ensuring that systems operate optimally and safely. One such component is the mid clamp. Although it may seem insignificant at first glance, the mid clamp possesses essential functions that contribute to the overall efficiency and safety of electrical systems, particularly in high-voltage applications. This article explores what mid clamps are, their functions, and their importance in the electrical industry.

What Is a Mid Clamp?

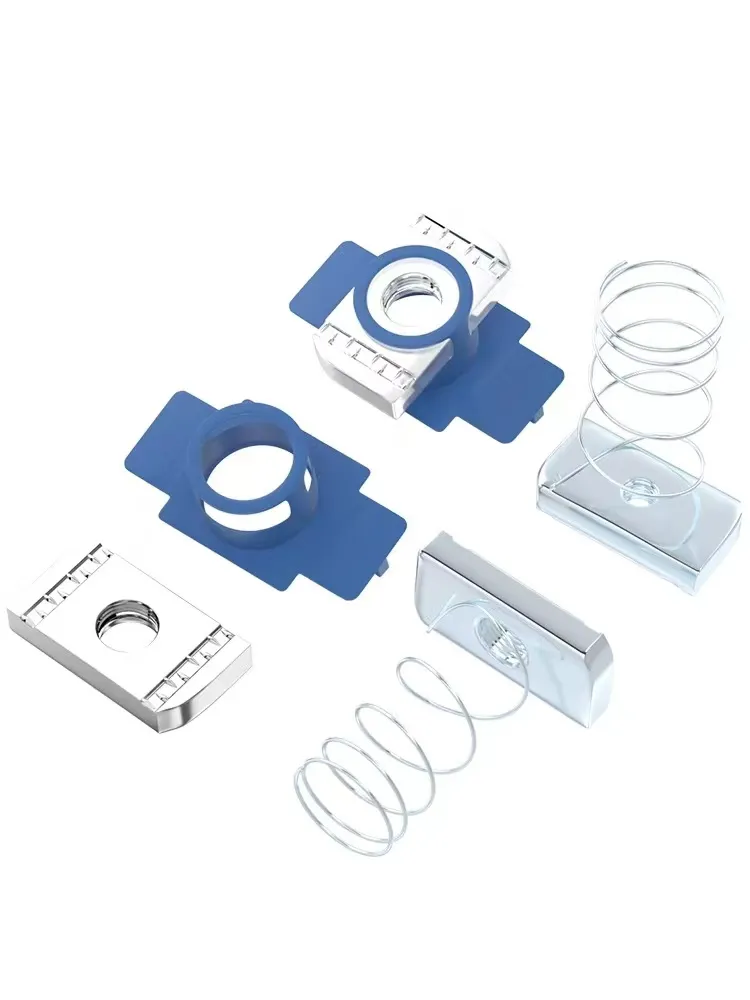

A mid clamp is an electrical connector designed to secure, support, and stabilize electrical conductors within various systems. Its primary purpose is to hold wires or cables in place, preventing any movement that could result in wear, stress, or damage to the conductors. Mid clamps are crucial in busbar systems, power distribution, and renewable energy applications, where reliable connectivity and stability are paramount.

Often made from materials such as aluminum or stainless steel, mid clamps provide a robust and durable solution for securing electrical components. They come in various designs to accommodate different sizes and types of conductors, ensuring versatility in application. Whether it's for solar panel installation, power lines, or electrical panels, mid clamps play a critical role in maintaining system integrity.

Functions of Mid Clamps

Mid clamps serve several functions that collectively enhance the safety and performance of electrical systems

1. Mechanical Support Mid clamps provide mechanical support to electrical conductors, preventing sagging and subsequent damage. This is particularly important in outdoor installations where environmental factors, such as wind and temperature fluctuations, can exert additional forces on the conductors.

2. Vibration Dampening In settings where machinery operates, vibrations can affect the stability of electrical connections. Mid clamps help minimize these vibrations, reducing the risk of connector failure over time.

3. Heat Dissipation With electrical currents passing through conductors, heat generation is inevitable. Proper clamping ensures that heat is distributed evenly, reducing the likelihood of hotspots that could lead to insulation failure or catastrophic system failure.

mid clamp

4. Electrical Connectivity A well-designed mid clamp ensures that electrical connections are secure, minimizing resistance and potential failure points. This is particularly critical in high-power applications where even small inconsistencies can have significant implications.

5

. Corrosion Resistance Given that many installations occur outdoors, mid clamps are often designed with materials that resist corrosion. This characteristic extends the lifespan of the component and the overall electrical system.Importance of Mid Clamps in the Electrical Industry

The importance of mid clamps cannot be understated in the electrical industry. They are particularly relevant in large-scale applications such as substations, wind farms, and solar power plants. In these environments, ensuring that all components are stable and securely connected is essential for operational efficiency and safety.

1. Safety Standards Compliance Many electrical systems must comply with local and international safety standards. Using high-quality mid clamps helps ensure that systems meet these standards, reducing the likelihood of accidents or failures.

2. Cost-Effectiveness By preventing damage to conductors and reducing the need for maintenance and repairs, mid clamps contribute to the cost-effectiveness of electrical installations. Ensuring long-term stability translates to fewer disruptions and lower operational costs.

3. Environmental Considerations As renewable energy installations, such as solar and wind, become increasingly prevalent, mid clamps play a vital role in eco-friendly energy solutions. Robust connections and support mechanisms enable these systems to function effectively, delivering clean energy to the grid.

4. Innovation and Development The ongoing advancements in materials science and engineering have led to the development of improved mid clamp designs. These innovations contribute to more efficient electrical systems, embracing the shift towards automation and smart grid technologies.

Conclusion

In conclusion, mid clamps are more than just simple connectors; they are integral components that ensure the reliability, safety, and efficiency of electrical systems across various applications. From providing mechanical support to enhancing electrical connectivity, their role in the electrical industry is indispensable. As technology continues to advance, the importance of mid clamps will only continue to grow, reinforcing their status as a cornerstone in modern electrical engineering. Understanding and utilizing these components effectively is essential for anyone involved in the design, implementation, or maintenance of electrical systems.

Latest news

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Customization

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

High-Strength Hot-Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, High Strength

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance, Grade 8.8

NewsJul.30,2025