Hexagon Washer Flange Tapping Screw With EPDM Rubber Gasket

Feb . 15, 2025 15:26 Back to list

Hexagon Washer Flange Tapping Screw With EPDM Rubber Gasket

M8 mudguard washers might seem like a simple component within various construction and automotive projects, yet their importance cannot be understated. These reliable and specially designed washers deliver significant benefits, especially in applications involving soft or oversized materials. Their distinct features, coupled with expert utilization, lend greatly to improved structural stability. Let's delve into their significance, usage, and best practices associated with M8 mudguard washers to underscore their utility and enhance project outcomes.

The authority of M8 mudguard washers also lies in their standardization and compliance within industry norms. Manufactured from high-quality materials such as stainless steel or zinc-plated steel, these washers are resilient to corrosion and environmental degradation. Their standardized specifications ensure compatibility with M8 fixtures, making them indispensable in environments subject to rigorous quality controls. By adhering to established metrics, these washers earn trust among engineers and builders. Furthermore, credibility strengthens through an understanding of procurement and quality assurance practices. Trustworthiness in deploying M8 mudguard washers is enhanced by sourcing from reputable manufacturers known for precision engineering. Reviews from seasoned technicians and feedback loops from extensive usage across sectors contribute to refining their effectiveness. Keeping abreast of industry advancements and the introduction of innovative materials like polymer-coated alternatives extends the beneficial options available to experts. Practical case studies highlight the transformative impact M8 mudguard washers have on project efficiency and product durability. In one scenario, a furniture production company faced issues with joint stability and customer returns due to ineffective fasteners. By integrating M8 mudguard washers into their assembly line, the company witnessed a 30% reduction in complaints related to product assembly stability. This integration not only safeguarded material integrity but also enhanced customer satisfaction and business reputation. In conclusion, M8 mudguard washers may appear to be a minor facet of construction or repair tasks, yet they epitomize precision engineering's critical detail. Their purposeful use not only enhances structural efficacy but also contributes to the realms of safety and material preservation. For professionals seeking reliable, authoritative, and trustworthy fastening solutions, integrating M8 mudguard washers into project protocols serves as both a strategic and practical enhancement, ensuring a higher calibre output and fostering industry confidence.

The authority of M8 mudguard washers also lies in their standardization and compliance within industry norms. Manufactured from high-quality materials such as stainless steel or zinc-plated steel, these washers are resilient to corrosion and environmental degradation. Their standardized specifications ensure compatibility with M8 fixtures, making them indispensable in environments subject to rigorous quality controls. By adhering to established metrics, these washers earn trust among engineers and builders. Furthermore, credibility strengthens through an understanding of procurement and quality assurance practices. Trustworthiness in deploying M8 mudguard washers is enhanced by sourcing from reputable manufacturers known for precision engineering. Reviews from seasoned technicians and feedback loops from extensive usage across sectors contribute to refining their effectiveness. Keeping abreast of industry advancements and the introduction of innovative materials like polymer-coated alternatives extends the beneficial options available to experts. Practical case studies highlight the transformative impact M8 mudguard washers have on project efficiency and product durability. In one scenario, a furniture production company faced issues with joint stability and customer returns due to ineffective fasteners. By integrating M8 mudguard washers into their assembly line, the company witnessed a 30% reduction in complaints related to product assembly stability. This integration not only safeguarded material integrity but also enhanced customer satisfaction and business reputation. In conclusion, M8 mudguard washers may appear to be a minor facet of construction or repair tasks, yet they epitomize precision engineering's critical detail. Their purposeful use not only enhances structural efficacy but also contributes to the realms of safety and material preservation. For professionals seeking reliable, authoritative, and trustworthy fastening solutions, integrating M8 mudguard washers into project protocols serves as both a strategic and practical enhancement, ensuring a higher calibre output and fostering industry confidence.

Latest news

-

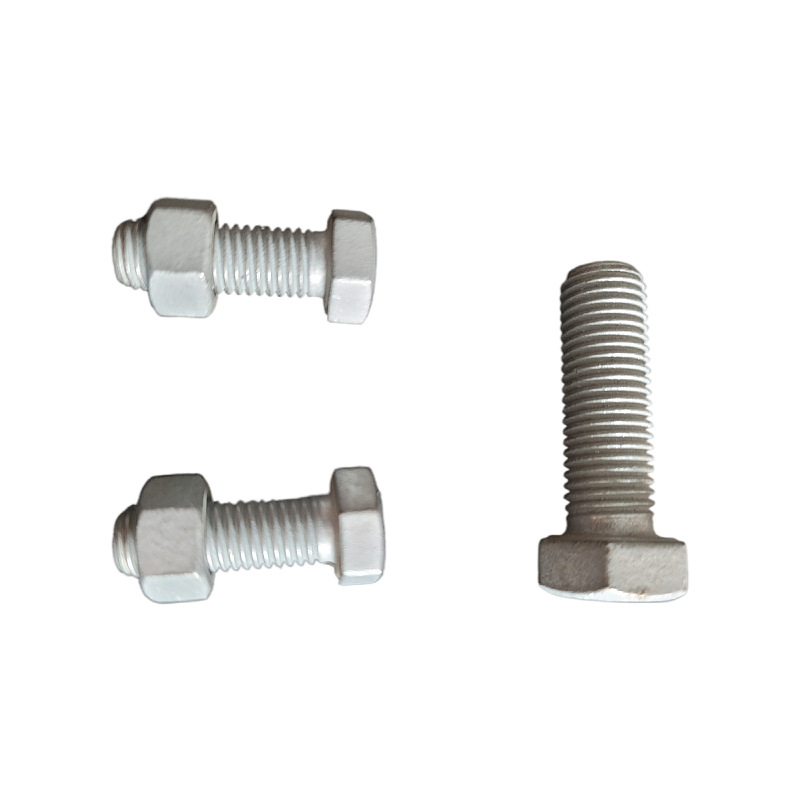

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Customization

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

High-Strength Hot-Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, High Strength

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance, Grade 8.8

NewsJul.30,2025