m6 weld stud

Oct . 11, 2024 14:12 Back to list

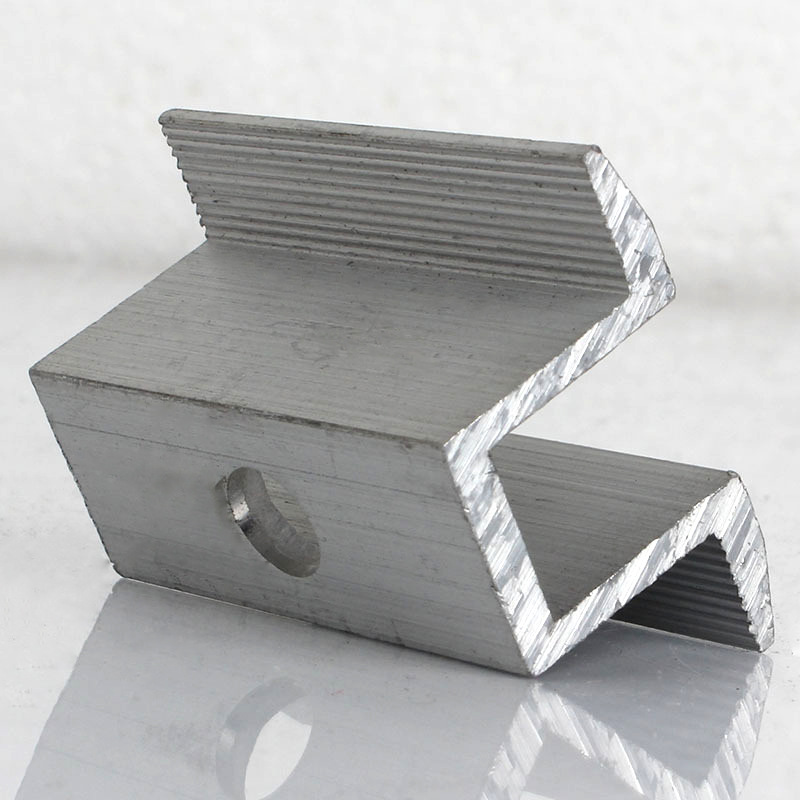

m6 weld stud

Understanding M6% Weld Studs

Weld studs, a vital component in various industrial applications, are designed to create strong, reliable connections in a range of materials. The M6% weld stud is a specific type that has garnered attention for its versatility and effectiveness in numerous fields such as construction, automotive, and electronics. This article delves into the intricacies of M6% weld studs, exploring their characteristics, applications, and benefits.

Definition and Characteristics

An M6% weld stud typically refers to a stud with a nominal diameter of 6mm that is utilized in welding processes to create durable and stable connections. The '%' in the designation often indicates specific alloy compositions or tensile strengths that enhance the stud's performance in various environments. These studs can come in various lengths and head styles, including flat, dome, and hex heads, allowing for further customization based on specific project requirements.

Manufacturing Process

The production of M6% weld studs involves several steps to ensure optimal performance and durability. Initially, high-quality raw materials, usually steel or alloys, are selected for their strength and corrosion resistance. The studs are then shaped using techniques such as machining or cold forming. After forming, the studs undergo processes like heat treatment, which enhances their mechanical properties by increasing hardness and tensile strength. Finally, surface treatments may be applied to improve corrosion resistance and prolong service life.

Applications

m6 weld stud

The applications for M6% weld studs are vast. In the automotive industry, they are commonly used to attach components to vehicle bodies, ensuring structural integrity and safety. In construction, these studs are utilized for mechanical fastening in steel structures, contributing significantly to the overall stability of builds. Additionally, in the electronics field, M6% weld studs are employed to create secure ground connections in various electronic enclosures, protecting sensitive components from electrical surges.

Benefits of Using M6% Weld Studs

One of the primary advantages of M6% weld studs is their ability to create strong, permanent connections. Unlike traditional fastening methods such as bolts or screws, which may loosen over time due to vibration and stress, weld studs offer a fixed connection that can withstand harsh environmental conditions. This stability is particularly crucial in structures exposed to dynamic loads or vibrations.

Furthermore, the installation of weld studs is often more efficient. The welding process can significantly reduce the time required for fastening components, leading to increased productivity on the manufacturing floor or construction site. Additionally, using weld studs generally results in a lighter assembly compared to bolts, reducing the overall weight of the structures or devices.

Conclusion

M6% weld studs exemplify the intersection of innovation and practicality in fastening technology. Their robust design, reliable performance, and versatility make them an essential component in various industries, from automotive to construction. As technology advances and industries continue to seek efficient and durable solutions, M6% weld studs will undoubtedly remain a critical fixture in modern engineering practices. Understanding their characteristics and applications enables professionals to make informed choices, ensuring safety and reliability in their projects.

Latest news

-

Hot Dip Galvanized Bolts-About LongZe|High Strength, Corrosion Resistance

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Customization

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

High-Strength Hot-Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, High Strength

NewsJul.30,2025