m5 flat washer

Nov . 13, 2024 02:08 Back to list

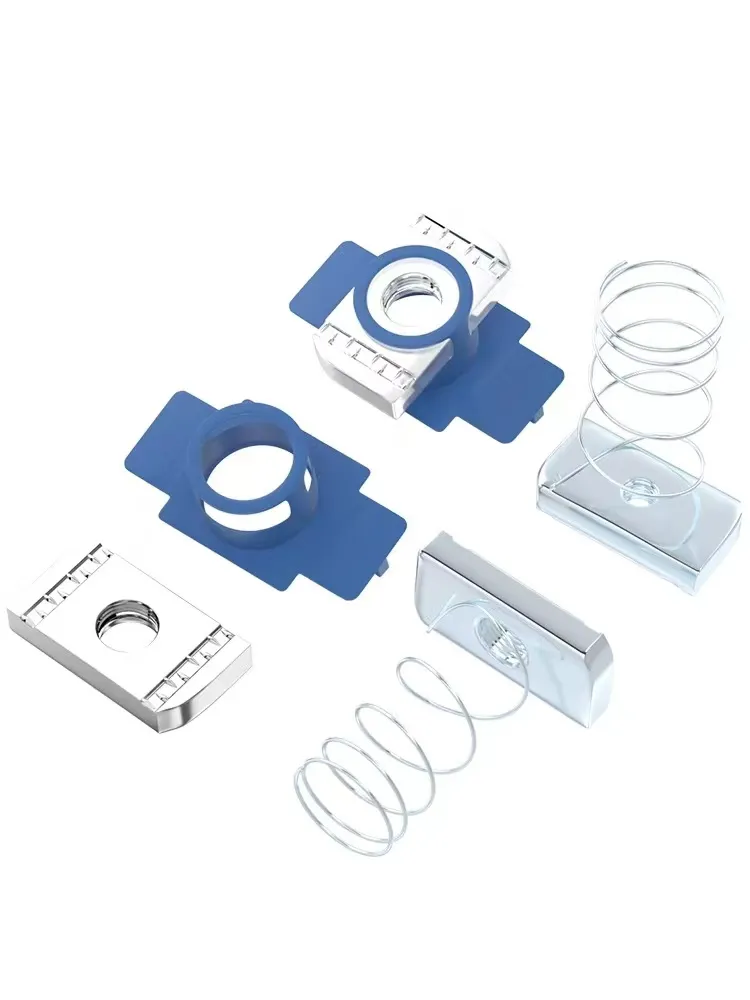

m5 flat washer

Understanding the M5 Flat Washer A Key Component in Fastening

In the world of mechanical engineering and construction, the importance of small components often goes unnoticed. Among these humble yet crucial elements is the M5 flat washer, a simple disc-shaped piece of metal or plastic that plays a vital role in numerous applications. This article delves into the significance of M5 flat washers, their specifications, uses, and benefits.

What is an M5 Flat Washer?

The term M5 refers to the standard metric size of the washer, specifically designed to fit M5 (5 mm diameter) bolts and screws. The flat washer is typically made from various materials, including stainless steel, zinc-plated steel, and plastic. Its primary function is to distribute the load of a threaded fastener, such as a screw or bolt, over a larger area. This load distribution helps to prevent damage to the surfaces being joined and ensures a more secure and stable connection.

Specifications and Types

M5 flat washers typically have an outer diameter larger than their inner diameter, providing a bearing surface that enhances the joint's strength. They come in various thicknesses to accommodate different applications. Standard thickness for M5 washers usually ranges from 0.5 mm to 3 mm. Additionally, washers can be classified based on their material properties, with options like stainless steel offering corrosion resistance, making them ideal for outdoor or humid environments.

Applications of M5 Flat Washers

M5 flat washers are utilized across various industries, including automotive, construction, electronics, and machinery. In automotive applications, they help secure components together, such as when attaching brackets or panels to a vehicle's chassis. In construction, M5 washers are often used in fastening elements of structures, ensuring the safety and integrity of buildings. In electronics, they assist in securing printed circuit boards (PCBs) or other components, providing a reliable connection that can endure vibrations and thermal expansion.

m5 flat washer

Advantages of Using M5 Flat Washers

Using flat washers, particularly M5 sizes, offers several advantages

1. Load Distribution By spreading the load over a wider surface area, washers reduce the stress on the connected materials, minimizing the risk of damage.

2. Protection They serve as a shield between the fastener and the surface, preventing wear and tear that could lead to failure over time.

3. Vibration Resistance In applications involving movement or vibration, flat washers can help maintain a secure connection by reducing loosening and shifting.

4. Improved Aesthetics Flat washers can provide a neater, more finished look to assemblies by concealing the embellishments of screws and bolts.

Conclusion

The M5 flat washer may seem like a minor component, but its role is integral in creating secure and reliable connections in various applications. Its ability to distribute load, protect surfaces, and enhance the longevity of assemblies makes it a must-have in any toolkit. Whether you are a professional engineer or a DIY enthusiast, understanding the function and benefits of M5 flat washers allows for more informed decisions in construction and repair projects, ultimately leading to better outcomes in terms of safety and durability.

Latest news

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Customization

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

High-Strength Hot-Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, High Strength

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance, Grade 8.8

NewsJul.30,2025