m4 steel washers

Dec . 04, 2024 13:56 Back to list

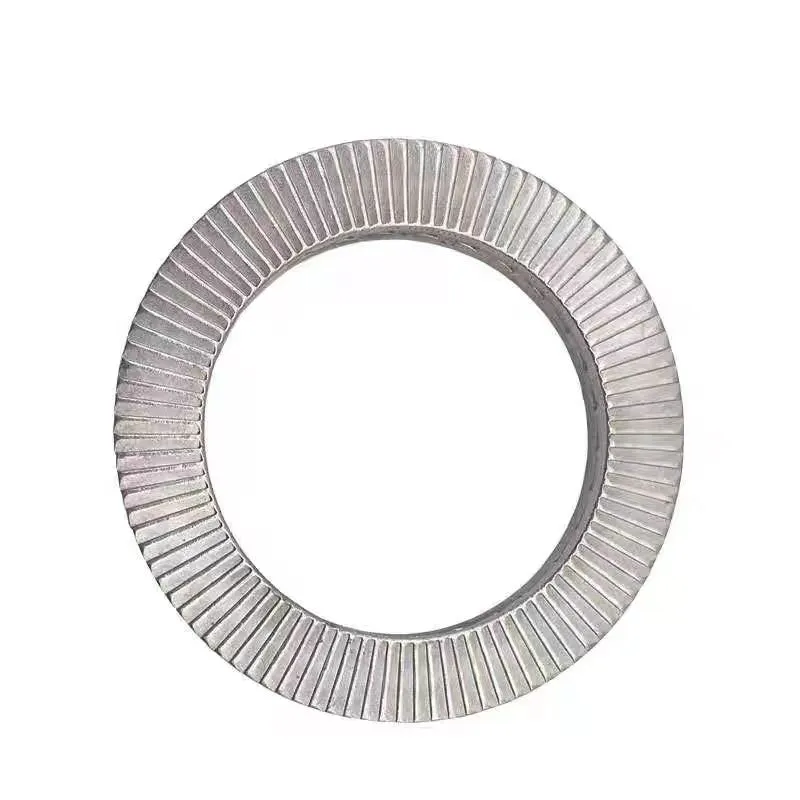

m4 steel washers

Understanding M4 Steel Washers The Unsung Heroes of Fastening

In the world of engineering and construction, the importance of choosing the right hardware cannot be overstated. Among these essential components are washers, specifically M4 steel washers. While these small discs may seem insignificant at first glance, they play a crucial role in ensuring the stability and reliability of various mechanical assemblies.

What is an M4 Steel Washer?

An M4 steel washer is a thin disc with a hole in the center, designed to distribute the load of a threaded fastener, such as a screw or bolt. The M4 designation indicates that the washer is suitable for use with fasteners that have a nominal diameter of 4 millimeters. Steel, as a material, provides the washer with strength and durability, making it suitable for a range of applications.

Washers come in various sizes and materials, but M4 steel washers are particularly valued for their strength, corrosion resistance, and versatility. They are widely used in automotive, aerospace, and construction industries, among others, to secure and stabilize components in assembly.

The Functions of M4 Steel Washers

1. Load Distribution One of the primary functions of washers is to distribute the load of the fastener over a larger surface area. This prevents the fastener from cutting into the material being fastened, which can lead to structural failure. For example, when securing a metal plate with screws, an M4 washer helps spread the load evenly, reducing the likelihood of deformation.

2. Preventing Damage M4 steel washers protect the surface of the materials being joined. Without washers, the edges of the fastener can dig into the surface, causing scratches or indentations, especially in softer materials. By providing a smooth barrier, washers ensure a tidy and professional finish.

3. Reducing Wear and Tear Over time, friction between components can lead to wear. Washers, particularly those designed with features like a spring effect or a special coating, can reduce friction and prevent wear, extending the lifespan of both the fastener and the components it secures.

m4 steel washers

4. Vibration Resistance In applications where there is a considerable amount of vibration, such as in automotive or machinery contexts, steel washers can help maintain the integrity of the connection. By absorbing some of the vibrations, they prevent the fastener from loosening over time.

5. Corrosion Resistance While not all M4 steel washers are coated, many are treated or galvanized to resist rust and corrosion. This feature is critical in environments where exposure to moisture or chemicals could compromise the integrity of the fastening system.

Choosing the Right M4 Steel Washer

When selecting M4 steel washers, the material, finish, and type of washer are crucial factors to consider. Common types include flat washers, spring washers, and lock washers, each serving specific purposes.

- Flat Washers These are the most common type and are used primarily for load distribution. - Spring Washers Designed to offer a spring effect, they help maintain tension and resist loosening.

- Lock Washers These washers have unique designs that help prevent rotation of the fastener, providing additional security in high-vibration applications.

It is also important to consider the environmental conditions the washers will face. For example, in marine applications or areas prone to chemical spills, stainless steel or copper washers might be more appropriate due to their superior corrosion resistance.

Conclusion

In conclusion, M4 steel washers are more than mere accessories; they are vital components that enhance the performance and durability of fastening systems. Understanding their functions and selecting the appropriate type is essential for engineers and builders alike. As industries increasingly strive for reliability and efficiency, the importance of these unsung heroes of fastening cannot be overlooked. Investing in high-quality M4 steel washers is not just a choice; it's a commitment to excellence in engineering and construction.

Latest news

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Customization

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

High-Strength Hot-Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, High Strength

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance, Grade 8.8

NewsJul.30,2025