Exploring the Benefits and Varieties of M4 Nuts for Your Health and Diet

Oct . 04, 2024 19:06 Back to list

Exploring the Benefits and Varieties of M4 Nuts for Your Health and Diet

The Fascinating World of M4 Nuts A Comprehensive Guide

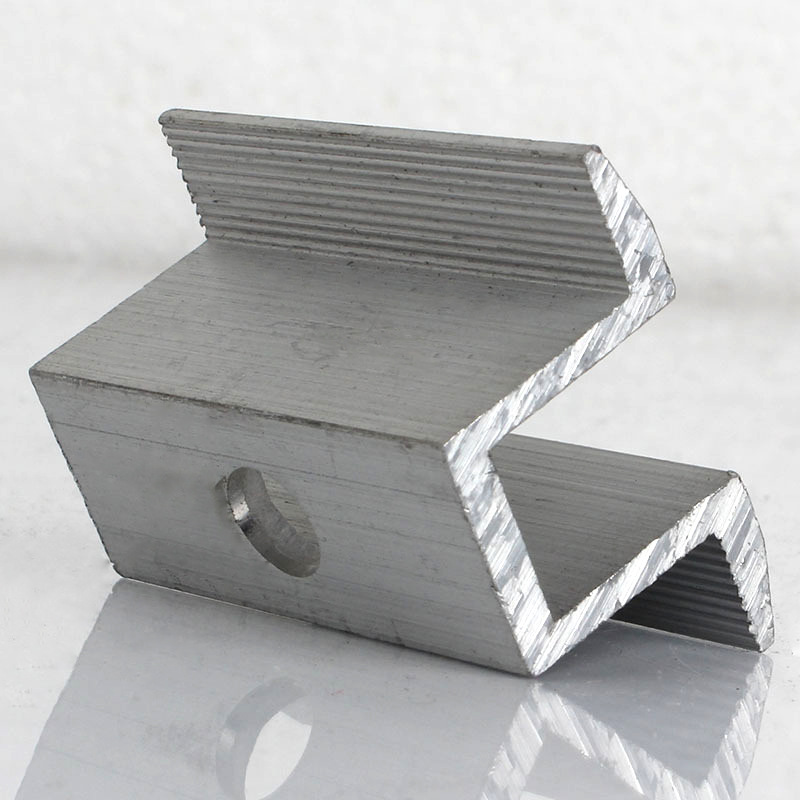

In the realm of mechanical engineering and assembly, nuts play a critical role in ensuring the stability and integrity of constructions. Among the various types of nuts available, the M4 nut stands out as a versatile and widely used component. This article explores the characteristics, applications, and importance of M4 nuts in various industries.

.

One notable aspect of M4 nuts is their compatibility with M4 bolts and screws, creating a secure and reliable fastening system. This compatibility is essential in various fields such as construction, automotive, electronics, and furniture manufacturing. The choice of material and finish for M4 nuts can significantly affect their performance. A zinc-plated M4 nut, for example, offers additional protection against rust and enhances its durability when exposed to the elements.

m4 nuts

M4 nuts are commonly used in assembling machinery and equipment where space is limited but strength is required. They are integral to the assembly of devices like bicycles, computer hardware, and automotive parts. In these applications, using the right torque when fastening the M4 nut onto the corresponding bolt is crucial. An insufficient torque can lead to a loose connection, while over-tightening can strip the threads or damage the components involved.

The importance of M4 nuts extends beyond their mechanical properties; they also play a significant role in safety. In automotive engineering, for instance, ensuring that all M4 nuts are fastened correctly is vital to the vehicle's overall safety and performance. A loose nut could lead to catastrophic failures, whereas a well-secured nut contributes to the integrity of the structure.

Moreover, M4 nuts are particularly favored in the realm of hobbyist projects and DIY applications. Many hobbyists utilize M4 nuts in assembling custom electronics, robotics projects, and model airplanes. The ease of availability and the wide range of complementary fasteners make M4 nuts a go-to component for enthusiasts looking to create something unique.

In summary, M4 nuts may be small, but their impact on various industries and applications is significant. Their versatility, durability, and ease of use make them a staple in both professional and DIY settings. Understanding the characteristics and proper applications of M4 nuts can help engineers and hobbyists alike to create safer, more efficient constructions. As technology continues to evolve, so too will the innovations surrounding fasteners like the M4 nut, ensuring they remain a crucial element in engineering and manufacturing for years to come.

Latest news

-

Hot Dip Galvanized Bolts-About LongZe|High Strength, Corrosion Resistance

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Customization

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

High-Strength Hot-Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, High Strength

NewsJul.30,2025