M18 1.5 Flange Nut Specifications and Applications for Various Industries

Nov . 25, 2024 04:40 Back to list

M18 1.5 Flange Nut Specifications and Applications for Various Industries

Understanding the M18 201.5 Flange Nut A Critical Component in Engineering

In the world of engineering and mechanical design, the importance of fasteners cannot be overstated. Among these, the M18 201.5 flange nut stands out due to its unique design and versatile applications. This specialized fastener plays a crucial role in providing secure connections in a variety of mechanical assemblies.

Understanding the M18 201

.5 Flange Nut A Critical Component in EngineeringOne of the primary advantages of the flange nut is its ability to distribute the load over a wider area, which reduces the risk of damage to the surface being fastened. This makes it ideal for applications involving softer materials, where traditional nuts might dig in and compromise structural integrity. Additionally, the flange helps to prevent loosening, serving as a locking mechanism when properly torqued.

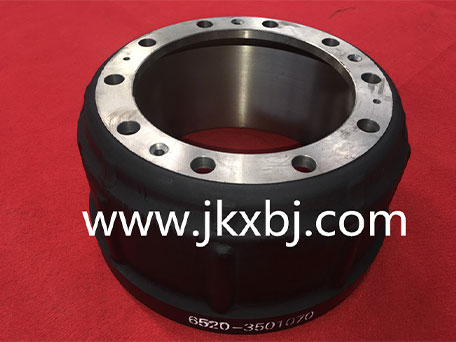

m18 1.5 flange nut

Flange nuts are extensively used in automotive, construction, and industrial applications. In the automotive industry, they can be found in engine assemblies, chassis connections, and suspension systems, ensuring that vital components remain securely attached despite continuous vibration and strain. In construction, these nuts are often used for securing structural components, providing peace of mind that buildings and infrastructures remain stable under various loads.

Aside from their mechanical benefits, flange nuts are crafted from a variety of materials, including steel, stainless steel, and even non-ferrous metals to withstand specific environmental conditions. Corrosion resistance is a key consideration, especially in outdoor or harsh environments where moisture and chemicals can compromise fastener integrity.

When selecting an M18 201.5 flange nut for a project, engineers must also consider the appropriate torque specifications to ensure optimal performance. This ensures that the nut performs effectively without over-torquing, which could lead to failure.

In conclusion, the M18 201.5 flange nut is a vital component in engineering that combines design, functionality, and practicality. Its ability to secure connections reliably makes it an essential choice for various applications, ensuring safety and durability in mechanical systems. Understanding its properties and proper usage can significantly enhance the performance and longevity of any assembly it is used in.

Latest news

-

High-Strength Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, Customization

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

High-Strength Hot-Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&High Strength

NewsJul.30,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | Corrosion Resistance, High Strength

NewsJul.30,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance, Grade 8.8

NewsJul.30,2025