m14 1.5 flange nut

Dec . 16, 2024 14:06 Back to list

m14 1.5 flange nut

Understanding the M14 201.5 Flange Nut A Comprehensive Overview

In the world of mechanical engineering and construction, nuts and bolts play a crucial role in ensuring the integrity and stability of structures and machinery. Among the myriad of fasteners available, the M14 201.5 flange nut stands out due to its specific design and applications. This article aims to delve into the intricacies of the M14 201.5 flange nut, exploring its characteristics, uses, and advantages.

What is an M14 201.5 Flange Nut?

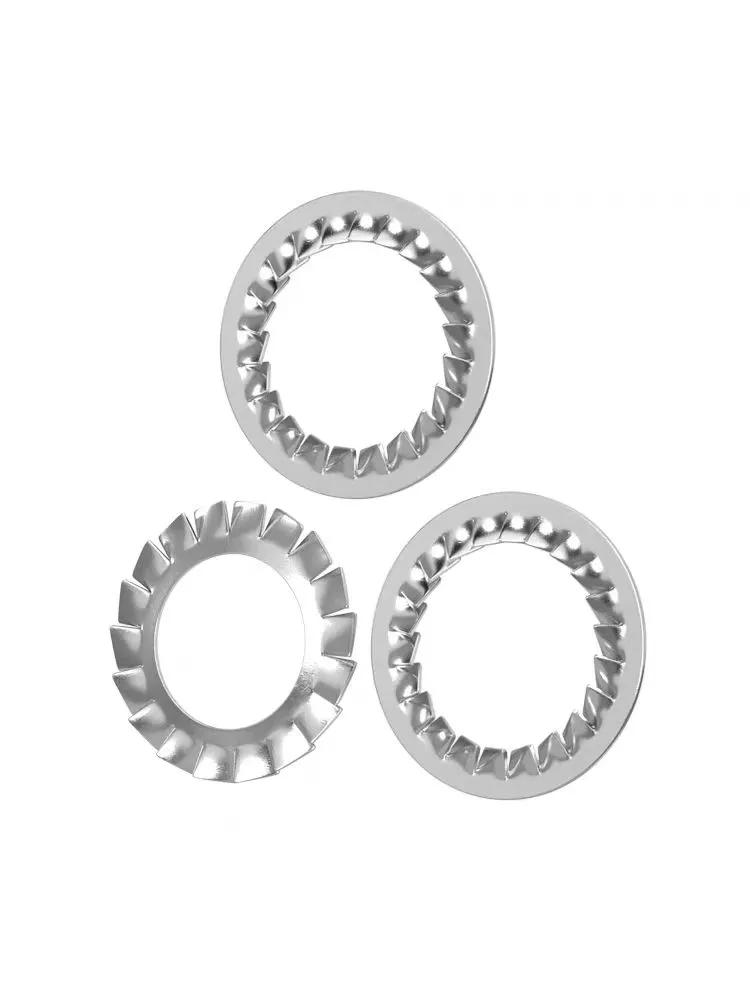

The designation M14 refers to the metric thread size, specifically indicating a nominal diameter of 14 millimeters. The 201.5 likely correlates to a specific measurement that defines the flange's characteristics or the nut's height. Flange nuts are distinct due to their integrated flange, which provides a wider bearing surface. This feature helps distribute the load over a larger area, reducing the risk of damage or failure in the material being fastened.

Flange nuts are commonly used in various industries, including automotive, construction, and machinery. Their design enables them to maintain a firm grip even under vibration and dynamic loads, making them ideal for applications where stability is paramount.

Key Features of M14 201.5 Flange Nuts

1. Thread Specifications The M14 flange nut features metric threads, conforming to international standards. The thread pitch can vary, but typically, it ranges around 2.0 mm for an M14 nut. This compatibility makes it easier to find matching bolts and screws.

2. Flange Design The flange design of the nut serves multiple purposes. It acts as a washer, providing additional surface area to prevent the nut from loosening over time and to ensure better contact with the surface of the material being fastened. The flange also helps in aligning parts during assembly.

3. Material Composition M14 201.5 flange nuts are usually made from durable materials such as carbon steel, stainless steel, or alloy steel. The choice of material affects the nut's strength, corrosion resistance, and suitability for various environments.

m14 1.5 flange nut

4. Finish Options Depending on where and how they are used, flange nuts can come with different finishes, such as zinc plating or black oxide. These finishes enhance corrosion resistance and provide aesthetic properties, particularly in visible applications.

Applications of M14 201

.5 Flange NutsM14 201.5 flange nuts find applications across various sectors

- Automotive Industry These nuts are frequently used in assembling various components such as engines and chassis, where vibration resistance is critical. - Construction In construction, they are utilized to secure structural components, ensuring stability and safety in building projects. - Manufacturing Machinery Machinery production often incorporates flange nuts in their assemblies, where they provide reliable fastening solutions under dynamic loads.

Advantages of Using M14 201.5 Flange Nuts

- Increased Load Distribution The flange design enhances load distribution, significantly reducing the chance of material damage. - Resistance to Loosening The wider bearing surface helps prevent the nut from loosening due to vibrations, a common issue in many industrial applications. - Versatility These nuts can be used in various applications across multiple industries, showcasing their versatility and practicality.

Conclusion

The M14 201.5 flange nut serves as a vital component in numerous fastening applications. Its unique characteristics, including metric thread specifications, a robust flange design, and material versatility, make it an excellent choice for industries that require reliability and stability. Understanding the features and benefits of flange nuts can aid engineers and construction professionals in making informed decisions when selecting fasteners for their projects. Whether in automotive assembly or construction frameworks, the M14 201.5 flange nut stands as a testament to the importance of quality fasteners in modern engineering.

Latest news

-

Premium Fasteners Manufacturer | AI-Driven Solutions

NewsAug.01,2025

-

Hot Dip Galvanized Bolts - Hebei Longze | High Strength, Corrosion Resistance

NewsAug.01,2025

-

High-Strength Hot Dip Galvanized Bolts - LongZe | Corrosion Resistance, Custom Sizes

NewsAug.01,2025

-

Best Self Tapping Screws for Drywall - Fast & Secure Installation

NewsJul.31,2025

-

High-Strength Hot Dip Galvanized Bolts-Hebei Longze|Corrosion Resistance&Customization

NewsJul.31,2025

-

Hot Dip Galvanized Bolts-Hebei Longze Metal Products|Corrosion Resistance&High Strength

NewsJul.31,2025